Heat & Glo • SL-750TRS-IPI-D, SL-550TRS-IPI-D, SL-350TRS-C • InD • 2065-985 Rev. o • 3/07

36

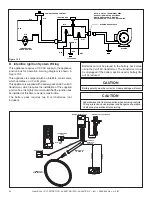

Figure 8.19 Assembling the Storm Collar

Figure 8.20 Assembling the Storm Collar Around the Pipe

Connect both halves of the storm collar with two screws

(see Figure 8.19).

Wrap the storm collar around the exposed pipe section

and align brackets. Insert a bolt (provided) through the

brackets and tighten nut to complete storm collar assembly

(see Figure 8.20).

Slide the assembled storm collar down the pipe section

until it rests on the roof

À

ashing.

Caulk around the top of the storm collar (see Figure

8.17).

CAUTION

Sharp Edges

• Wear protective gloves

and safety glasses dur-

ing installation.

Assembling and Installing Storm Collar