Heat & Glo • SL-36-Ultimate • 2141-900 Rev. i • 5/11

18

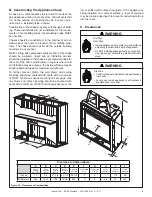

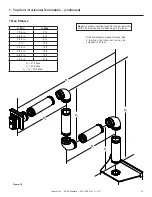

A. Pipe Clearances to Combustibles

6

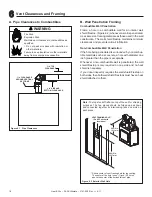

Vent Clearances and Framing

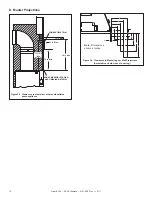

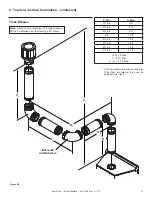

B. Wall Penetration Framing

Combustible Wall Penetration

Frame a hole in a combustible wall for an interior wall

shield fi restop, (Figure 6.2) whenever a wall is penetrated.

Use same size framing materials as those used in the wall

construction. The wall shield fi restop maintains minimum

clearances and prevents cold air infi ltration.

Non-Combustible Wall Penetration

If the hole being penetrated is surrounded by noncombus-

tible materials such as concrete, a hole with diameter one

inch greater than the pipe is acceptable.

Whenever a non-combustible wall is penetrated, the wall

shield fi restop is only required on one side and no heat

shield is necessary.

If your local inspector requires the wall shield fi restop on

both sides, then both wall shield fi restops must have a heat

shield attached to them.

Fire Risk.

Explosion Risk.

Maintain vent clearance to combustibles as

specifi ed.

• Do not pack air space with insulation or

other materials.

Failure to keep insulation or other materials

away from vent pipe may cause fi re.

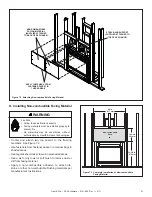

Figure 6.1 Pipe Clearances

1 in. CLEARANCE

AROUND VERTICAL

SECTIONS

3 in. TOP

CLEARANCE

1 in. SIDE AND

BOTTOM CLEARANCE

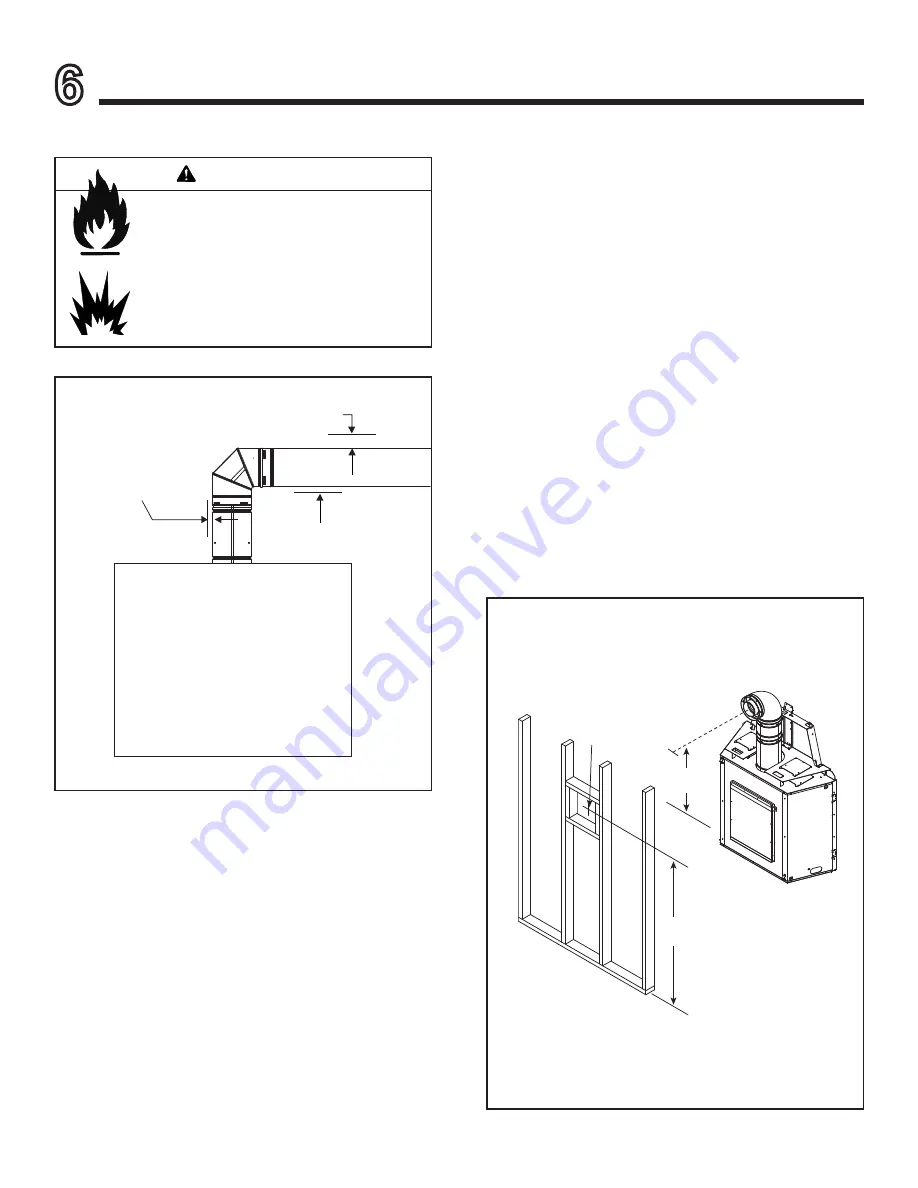

Figure 6.2 Exterior Wall Hole

* Shows center of vent framing hole for top venting.

The center of the hole is one (1) inch (25.4 mm)

above the center of the horizontal vent pipe.

VENT FRAMING HOLE*

(Do NOT pack with

Insulation)

60-1/2 in.

1537 mm

59-1/2 in.

1511 mm

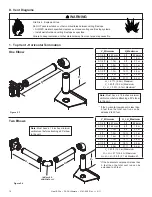

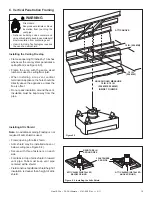

WARNING

Note:

The top standoff is fl at on top of the unit for shipping

purposes. The two pieces should be folded up as shown

and connected together by interlocking tabs and slots on

each piece.