Heat & Glo • SL-550 / 750 / 950TR-D • 2044-985 Rev. J • 6/06

33

For Vertical Runs -

The vent system must be supported

every eight (8) feet (2.4m) above the appliance flue outlet

by wall brackets. To install support brackets for vertical runs:

• Attach wall brackets to the vent pipe and secure the wall

bracket to the framing members with nails or screws.

Figure 23. Installing Support Brackets

2. Continue Adding Vent Components

• Continue adding vent components, locking each succeed-

ing component into place.

• Ensure that each succeeding vent component is secure-

ly fitted and locked into the preceding component.

• 90° elbows may be installed and rotated to any point

around the preceding component’s vertical axis. If an el-

bow does not end up in a locked position with the pre-

ceding component, attach with a minimum of two (2)

sheet metal screws.

Figure 22. Adding Venting Components

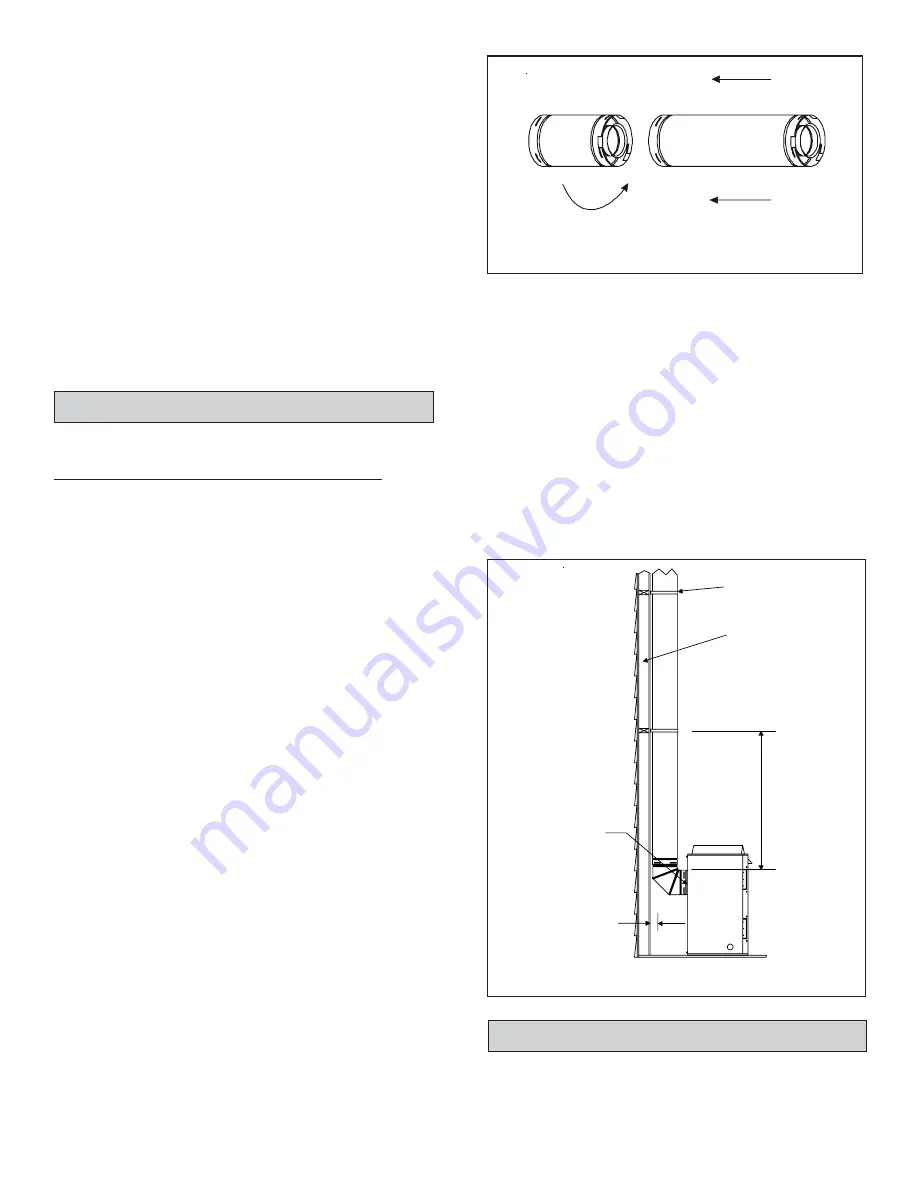

3. Install Support Brackets

For Horizontal Runs -

The vent system must be supported

every five (5) feet of horizontal run by a horizontal pipe support.

To install support brackets for horizontal runs:

• Place the pipe supports around the vent pipe.

• Nail the pipe supports to the framing members.

WALL BRACKET

WALL STUD

1 INCH MIN.

(25.4mm)

8 FT. (2.4m)

FLUE

OUTLET

If the installation is for a termination cap attached directly

to the appliance, skip to the sections,

Install Firestops

and

Vent Termination

.

SL-D and SL-Flex Series Venting Only:

1. Attach the First Vent Component to the

Starting Collars

To attach the first vent component to the starting collars

of the appliance:

• Lock the vent components into place by sliding the con-

centric pipe sections with four (4) equally spaced interior

beads into the appliance collar or previously installed com-

ponent end with four (4) equally spaced indented sections.

• When the internal beads of each outer pipe line up, ro-

tate the pipe section clockwise about one-quarter (1/4)

turn. The vent pipe is now locked together.

• Slide the ceramic fiber pad over the first vent section and

place it flush to the appliance (see Fig. 1). This will pre-

vent cold air infiltration. High temp caulk may be used to

hold the part in place. Continue to add vent components.

Go to Step 4 Install Firestops.

2. Continue Adding Vent Components

Refer to Cinch Pipe and Termination Cap installation in-

structions.

• Continue adding vent components, locking each succeed-

ing component into place.

• Ensure that each succeeding vent component is secure-

ly fitted and locked into the preceding component in the

vent system.

• 90° elbows may be installed and rotated to any point

around the preceding component’s vertical axis. If an el-

bow does not end up in a locked position with the pre-

ceding component, attach with a minimum of two (2)

sheet metal screws.

3. Install Support Brackets

Refer to Cinch Pipe and Termination Cap installation in-

structions.

Go to Step 4 Install Firestops.