MGD Gas Furnace

Service Manual

A 115-volt motor drives the exhaust blower. Basically there are only two problems that can be

experienced with this component. It can have a motor failure, or it can become noisy due to bad

bearings, loose blades, etc.

When servicing the blower be certain to insure that gaskets and sealing material are replaced.

Leaks can cause operational problems, such as the pressure switch not closing.

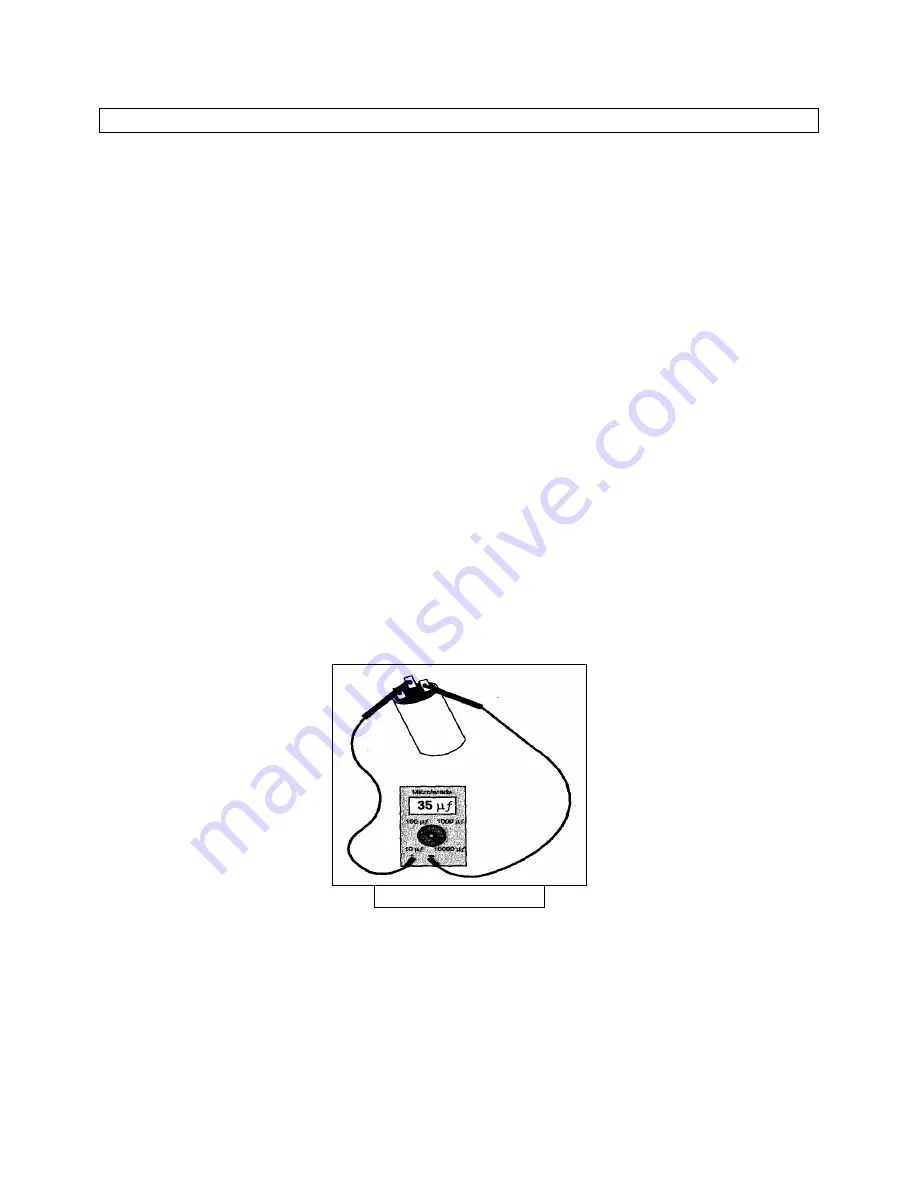

CAPACITORS

A permanent split capacitor is used for the circulating blower fan motor. Before replacing a motor,

the condition of the capacitor should be verified, since it, and not the motor may be the source of

the problem.

Before checking the capacitor, the supply power to the unit should be turned OFF.

The capacitor should then be discharged through a resistor before testing. A 20,000 Ohm 2 Watt

resistor can be used for this purpose.

The condition of the capacitor should be verified with a capacitor analyzer, one that indicates the

capacitor’s value in microfarads, rather than with an Ohmmeter. The reason for this is that an

Ohmmeter test can only indicate if a capacitor is OPEN, or SHORTED. It cannot verify if its

value (microfarads) is within an acceptable range.

Capacitor should test to within 10% of its rated value. Capacitors testing outside this range should

be replaced. A weak capacitor can be the cause of a motor failing to start, or failing to run at

proper speed.

Checking Capacitor

BLOWER ASSEMBLY

All models use a multi-speed, permanent split capacitor motor, direct-drive, blower assembly.

Different size (HP) motors and/or different diameter blower wheels are used in each model to

obtain the required airflow. The method for accessing and removing the blower motor/assembly

for servicing is described below.

15 of 22