28

If Your Fireplace

Has Direct Spark

Ignition (DSI)

Appliance Requirements

This appliance requires that 110-120 VAC be wired

to the factory installed junction box. Maintain correct

polarity when wiring the junction box.

NOTE

ELECTRICAL WIRING MUST BE INSTALLED BY

A LICENSED ELECTRICIAN.

Optional Accessories

Optional fan and remote control kits require that

110-120 VAC be wired to the fireplace junction box.

CAUTION

DISCONNECT REMOTE CONTROLS IF ABSENT

FOR EXTENDED TIME PERIODS TO PREVENT

ACCIDENTAL FIREPLACE OPERATION.

Wall Switch

Position the wall switch in the desired position on a

wall. Run a maximum of 25 feet (7.8 m) or less of

16 A.W.G. minimum Romex wire and connect it to

the fireplace ON/OFF switch pigtails.

CAUTION

LABEL ALL WIRES PRIOR TO DISCONNECTION

WHEN SERVICING CONTROLS. WIRING ERRORS

CAN CAUSE IMPROPER AND DANGEROUS OP-

ERATION. VERIFY PROPER OPERATION AFTER

SERVICING.

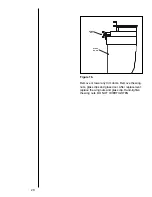

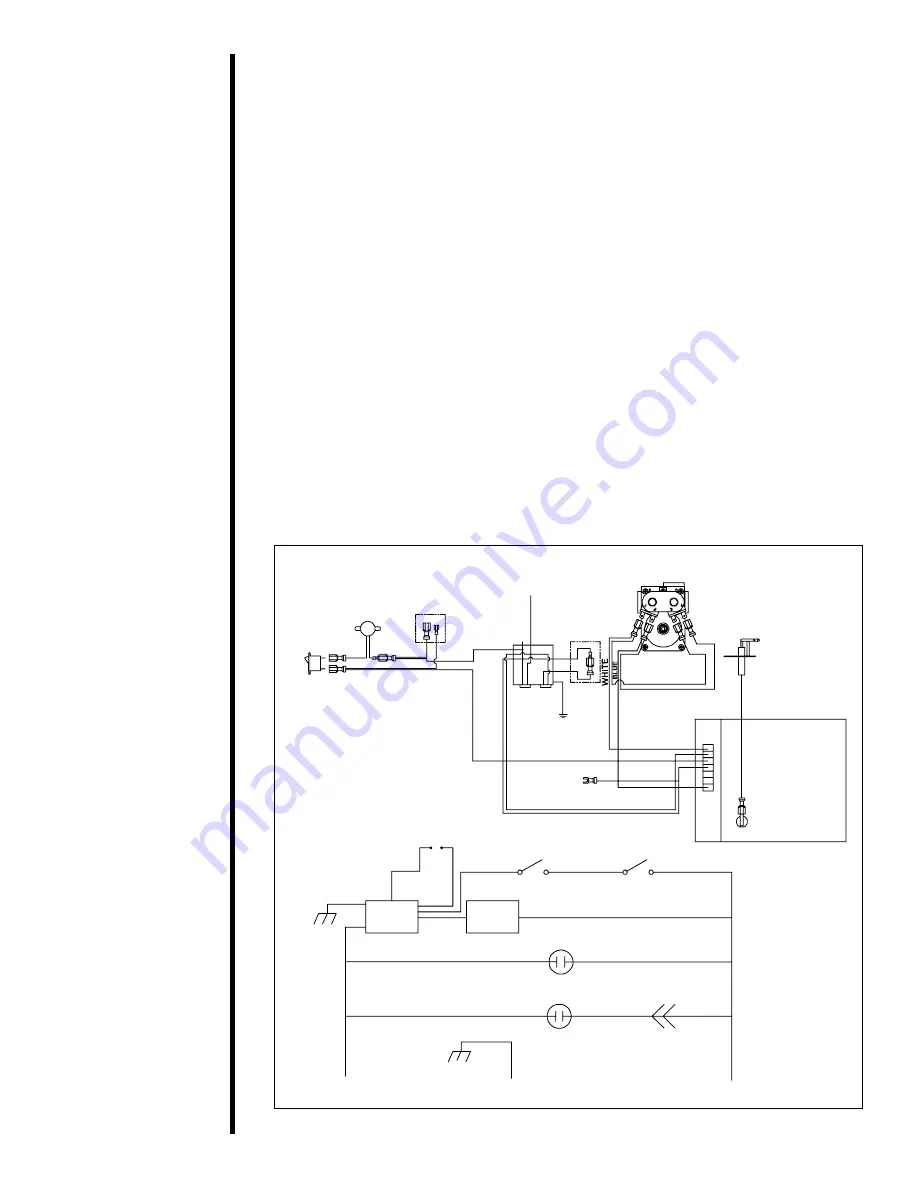

Figure 18. Direct Spark Ignition (DSI) Wiring Diagram

HI TEMP

LIMIT SWITCH

OPTIONAL REMOTE,

WALL SWITCH

OR THERMOSTAT

(ON CERTIFIED UNITS ONLY)

BLACK

GROUND

FAN

REN

OPTIONAL

FAN

SWITCHES

L2

(NEUTRAL)

L2

(HOT)

JUNCTION

BOX

120 VAC

ON/OFF

1

2

0

V

A

C

P

O

W

E

R

C

O

R

D

GROUND TO

FIREPLACE

CHASSIS

WHITE

BLACK

FLAME SENSOR/SPARKER

IGNITION

MODULE

GAS

VALVE

HI-TEMP

LIMIT SWITCH

ON/OFF SWITCH

WHITE

YELLOW

GREEN

BLUE

WHITE

BLUE

DSI

MODULE

O

R

A

N

G

E

IGNITOR

DSI CONTROL VALVE

REMOTE OUTLET

FAN OUTLET

CONNECTORS

HOT

GROUND

NEUTRAL