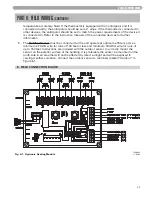

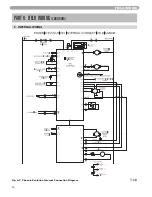

PART 6: FIELD WIRING

FIELD WIRING

A. FIELD WIRING COMPLIANCE REQUIREMENTS

INSTALLATION MUST COMPLY WITH:

1. National Electrical Code and any other national, state, provincial or local codes or regulations.

2. In Canada, CSA C22.1 Canadian Electrical Code Part 1, and any local codes.

B. FIELD WIRING

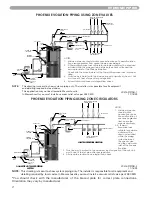

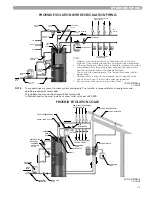

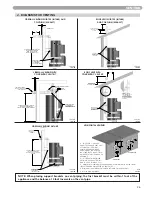

All the wiring connections made to the Phoenix Evolution in the field are done on the field connec-

tion board located on the right side of the cabinet. The cabinet has multiple knockouts available to

route field wiring into and out of the field connection board. The control provides a pump output

thermostat and outdoor sensor inputs to operate the central heating system.

C. LINE VOLTAGE WIRING

1.

Connect the normal

Incoming Power

to the terminals marked as shown in Figure 6-1. A line

voltage fused disconnect switch may be required to be externally mounted and connected

according to local codes and standards.

2.

Connect the

Central Heating Pump

as shown in Figure 6-1 the terminals marked CH/DHW

PUMP. The connection shown are suitable for a maximum continuous pump draw of 3 amps

at 120 volts. If the pump requires more current or voltage other than the 120 volts supplied,

an external motor starter will be required.

3.

Please note that the solar pump connectors on the field connection board are not functional

at this time.

D. LOW VOLTAGE WIRING

1.

Make all low voltage connections to the terminal strip located on the field connection board

(shown in Figure 6-1) as outlined below.

2.

The

Room Thermostat

should be connected to the terminals marked T STAT (shown in

Figure 6-1). Alternately, any dry contact closure across these terminals will cause the unit to

operate the hydronic heating module. NOTE: Caution must be used to ensure neither of the

terminals become connected to ground. Mount the thermostat on an inside wall as central as

possible to the area being heated, away from drafts or heat producing devices such as a

television etc. which could influence the ability of the thermostat to measure room

23

n

WARNING

ELECTRICAL SHOCK HAZARD — For your safety, turn off electrical power supply at

service entrance panel before making any electrical connections to avoid possible

electric shock hazard. Failure to do so can cause severe personal injury or death.

NOTICE

Wiring must be N.E.C. Class 1.

If original wiring as supplied with boiler must be replaced, use only TEW 105 °C wire

or equivalent.

Boiler must be electrically grounded as required by National Electrical Code ANSI/NFPA

70 — latest edition.

Summary of Contents for Phoenix Evolution

Page 71: ...70 ...

Page 72: ...71 ...

Page 73: ...72 MAINTENANCE NOTES ...

Page 74: ...73 MAINTENANCE NOTES ...

Page 75: ...74 MAINTENANCE NOTES ...

Page 76: ... 2009 Heat Transfer Products Inc www htproducts com LP 314 REV 12 21 09 ...