20

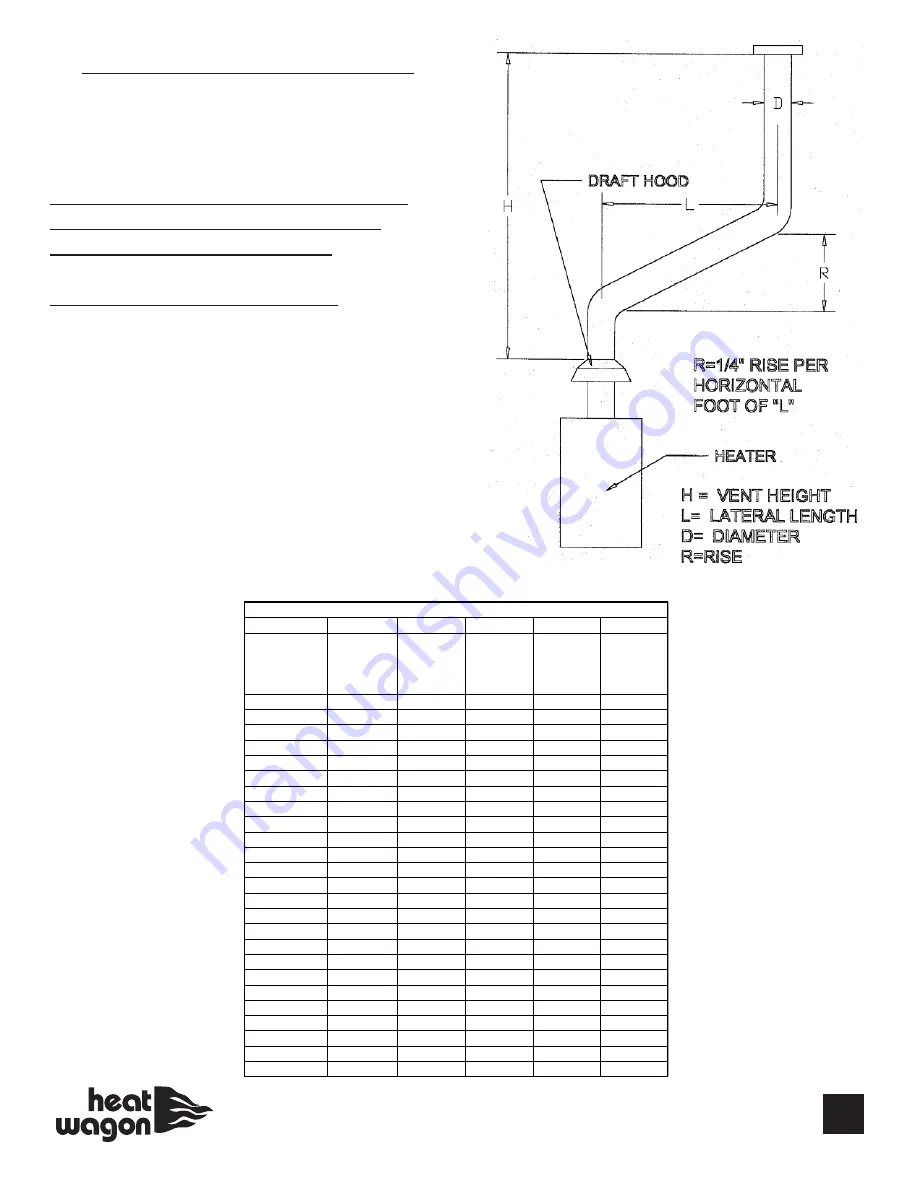

EXHAUST FLUE PIPE GUIDELINES

8

10

12

14

TOTAL

VENT

HEIGHT

((H

H))

F

EET

LATERAL

LENGTH

((LL))

FEET

6

0

370

570

850

1170

2

285

455

650

890

6

273

435

630

870

12

255

406

610

840

8

0

415

660

970

1320

2

322

515

745

1020

8

303

490

720

1000

16

281

458

685

950

10

0

450

720

1060

1450

2

355

560

850

1130

10

330

525

795

1080

20

300

486

735

1030

15

0

525

840

1240

1720

2

414

675

985

1350

15

373

610

905

1250

30

328

553

845

1180

20

0

575

930

1350

1900

2

470

755

1100

1520

10

443

710

1045

1460

20

410

665

990

1390

30

380

626

945

1270

30

0

650

1060

1550

2170

2

535

865

1310

1800

20

473

784

1185

1650

40

415

705

1075

1520

VENT DIAMETER (D) INCHES

CAPACITY OF TYPE B DOUBLE-WALL

VENTS SERVING A SINGLE DRAFT

HOOD-HEATER x 1000 BTU'S

FOR INDOOR APPLICATIONS

F

• The flue pipe is to be made of

non-combustible material and clearances

from combustible materials must be a

minimum 8 inches (temperature of flue

gases is approximately 410º F).

Flue pipe must be used at all times!

For flue pipe lengths over 21”, you must

increase the flue pipe diameter.

See chart below: