Heat & Glo • 6000C-IPI, 8000C-IPI • 2164-900 Rev. W • 8/14

44

10

10

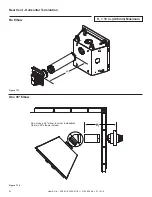

Installing Vent Pipe (DVP and SLP Pipe)

A. Assemble Vent Sections (DVP Pipe Only)

Attach Vent to the Firebox Assembly

Note:

The end of the pipe sections with the lanced tabs will face

toward the appliance.

Attach the

fi

rst pipe section to the starting collar:

• Lanced pipe end to the starting collar

• Inner pipe over inner collar

• Push the pipe section until all lanced tabs snap in place

• Lightly tug on pipe to con

fi

rm it has locked.

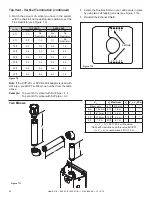

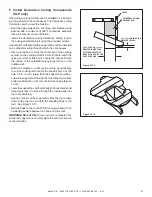

Figure 10.1 High Temperature Silicone Sealant

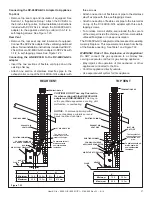

Figure 10.2

A

B

Figure 10.3

Assemble Pipe Sections

Per Figure 10.2:

• Start the inner pipe on the lanced end of section A into

the

fl

ared end of section B.

• Start the outer pipe of section A over the outer pipe of

section B.

• Once both vents sections are started, push

fi

rmly until

all lanced tabs lock into place.

• Lightly tug on the pipe to con

fi

rm the tabs have locked.

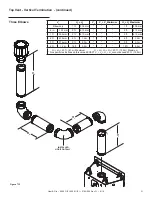

It is acceptable to use screws no longer than 1/2 in. (13

mm) to hold outer pipe sections together. If predrilling holes,

DO NOT

penetrate inner pipe.

For 90º and 45º elbows that are changing the vent direction

from horizontal to vertical, one screw minimum should be

put in the outer

fl

ue at the horizontal elbow joint to prevent

the elbow from rotating. Use screws no longer than 1/2

in. (13 mm). If predrilling screw holes,

DO NOT

penetrate

inner pipe.

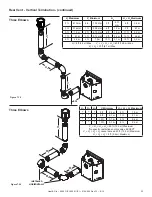

Commercial, Multi-family (Multi-level exceeding two sto-

ries), or High-Rise Applications

All outer pipe joints must be sealed with silicone with a

minimum of 300ºF continuous exposure rating, including the

slip section that connects directly to the horizontal termi-

nation cap.

• Apply a bead of silicone sealant inside the female outer

pipe joint prior to joining sections. See Figure 10.1

• Only outer pipes need to be sealed. All unit collar, pipe,

slip section, elbow and cap outer

fl

ues shall be sealed

in this manner, unless otherwise stated.

WARNING! Risk of Fire or Explosion! DO NOT

break

silicone seals on slip sections. Use care when remov-

ing termination cap from slip pipe. If slip section seals

are broken during removal of the termination cap, vent

may leak.

Figure 10.4 Seams

Note:

Make sure that the seams are not aligned to prevent

unintentional disconnection.

INCORRECT

CORRECT

Lances

Lances