Heat & Glo • Cosmo-I30-C, Cosmo-I35-C • 2239-901 Rev. S • 3/15

14

Burner Ignition and Operation

Frequency:

Annually

By:

Service Technician

Tools needed:

Protective gloves, vacuum cleaner, whisk

broom,

fl

ashlight, voltmeter, indexed drill bit set, and a

manometer.

• Verify burner is properly secured and aligned with pilot

or igniter.

• Clean off burner top, inspect for plugged ports, corrosion

or deterioration. Replace burner if necessary.

• Verify batteries have been removed from battery back-up

IPI systems to prevent premature battery failure or

leaking. For optimal battery life, locate the battery

pack outside of the control cavity on the hearth. This

placement will reduce the chances of overheating the

batteries during extended burns which could result in

reduced battery life or degradation.

• Check for smooth lighting and ignition carryover to all

ports. Verify that there is no ignition delay.

• Inspect for lifting or other

fl

ame problems.

• Verify air shutter setting is correct. See Section 12.G for

required air shutter setting. Verify air shutter is clear of

dust and debris.

• Inspect ori

fi

ce for soot, dirt and corrosion. Verify ori

fi

ce

size is correct. See Service Parts List for proper ori

fi

ce

sizing.

• Verify manifold and inlet pressures. Adjust regulator as

required.

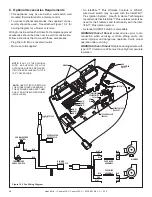

• Inspect pilot

fl

ame pattern and strength. See Figure 3.1

for proper pilot

fl

ame pattern. Clean or replace ori

fi

ce

spud as necessary.

• Inspect thermocouple/thermopile or IPI

fl

ame sensing

rod for soot, corrosion and deterioration. Polish with

fi

ne

steel wool or replace as required.

• Verify that there is not a short in

fl

ame sense circuit by

checking continuity between pilot hood and

fl

ame sense

rod. Replace pilot as necessary. (IPI only)

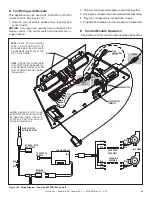

Figure 3.1 IPI Pilot Flame Patterns