19

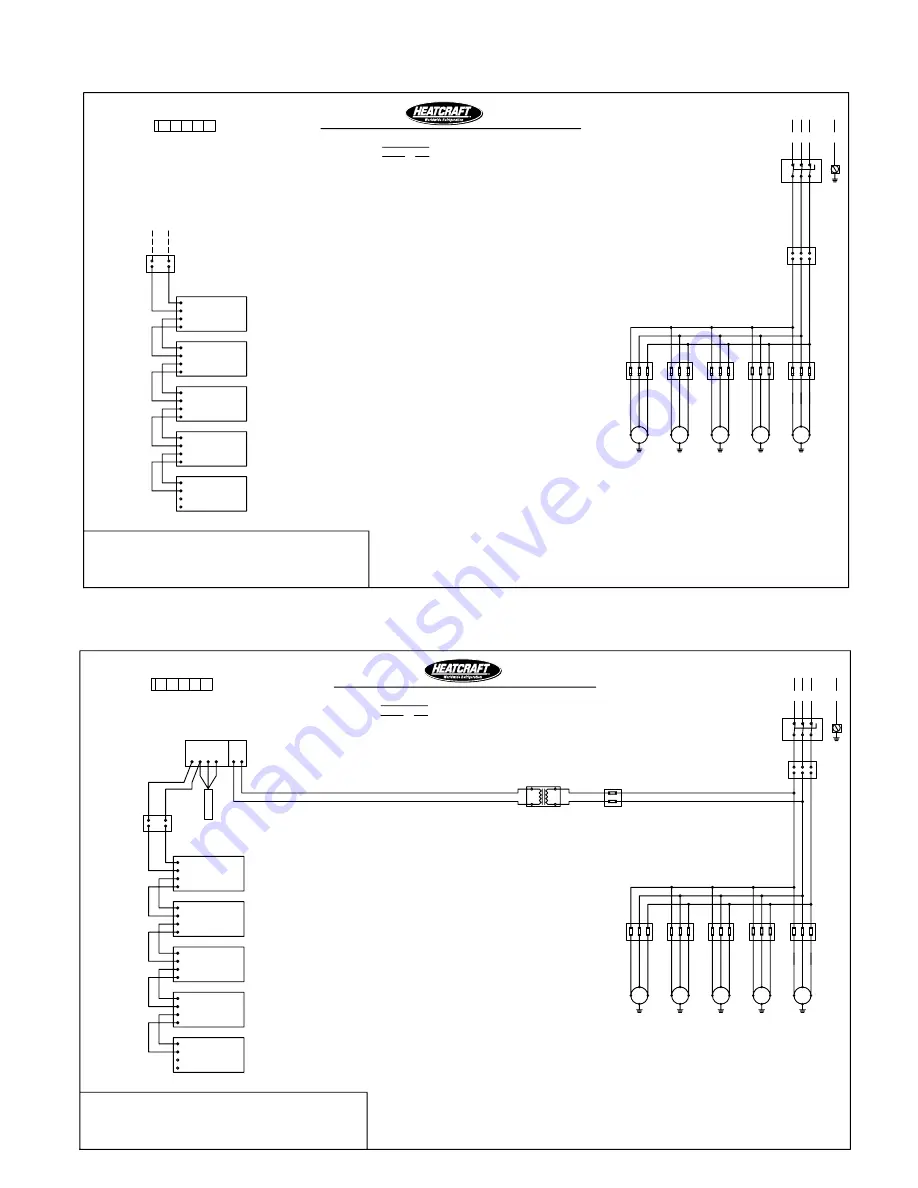

NOTE:

1. UNIT MUST BE GROUNDED.

2. TO BE FIELD FUSED, REFER TO UNIT DATAPLATE FOR VOLTAGE.

3. ALL MOTORS ARE INHERENTLY PROTECTED.

4. USE 60°C WIRE.

5. REFER TO LABEL ADJACENT FUSE HOLDER FOR REPLACEMENT.

USE COPPER CONDUCTORS ONLY

FIELD WIRING

FACTORY WIRING

C FAN CONTACTOR

M FAN MOTOR

F FUSES

R RELAY

FCC FAN CYCLE CONTROL (MAY BE PRESSURE OR TEMPERATURE)

PM POWER MODULE (USED ONLY W/SYSTEM 350 COMPONENTS)

A319 THERMOSTAT FAN CYCLE CONTROL

MTB MOTOR TERMINAL BOARD

TB TERMINAL BOARD

CB CIRCUIT BREAKER

R RELAY

LEGEND

FAN MOTOR IDENTIFICATION

HEADER EN

D

M1

BOARD 1

TERMINAL

T1

T2

T3

3ÿ/60Hz

DISCONNECT

SWITCH

L1

L2

L3

L3

L1

L2

OPERATION MODE: Open Loop, Pulse Width Modulation

PRIORITY: Poti

PE

ALL MOTORS TO BE PROGRAMMED AS FOLLOWS:

L1

PE

L2

M2

L3

PE

M3

L1

L3

L2

L2

PE

L1

M4

L3

PE

L3

L1

M5

L2

F1

F5

F3

F4

F2

4

3

2

1

EBO

X

5

0 to 10V DC

FAN SPEED CONTROL CIRCUIT

T2

TERMINAL

BOARD 2

T1

M5

7 - 0-10V PWM

1 - OUT

2 - GND

8 - GND

KL3

M4

7 - 0-10V PWM

1 - OUT

2 - GND

8 - GND

KL3

M3

7 - 0-10V PWM

1 - OUT

2 - GND

8 - GND

KL3

M2

7 - 0-10V PWM

1 - OUT

2 - GND

8 - GND

KL

3

M1

7 - 0-10V PWM

1 - OUT

2 - GND

8 - GND

KL

3

RED

BL

K

RE

D

BLK

RE

D

BLK

RE

D

BLK

BL

K

RED

Diagram 3. Typical EC Condenser Wiring Diagram with External Signal

Diagram 4. Typical EC Condenser Wiring Diagram with Proportional Pressure Control

NOTE:

1. UNIT MUST BE GROUNDED.

2. TO BE FIELD FUSED, REFER TO UNIT DATAPLATE FOR VOLTAGE.

3. ALL MOTORS ARE INHERENTLY PROTECTED.

4. USE 60°C WIRE.

5. REFER TO LABEL ADJACENT FUSE HOLDER FOR REPLACEMENT.

USE COPPER CONDUCTORS ONLY

FIELD WIRING

FACTORY WIRING

C FAN CONTACTOR

M FAN MOTOR

F FUSES

R RELAY

FCC FAN CYCLE CONTROL (MAY BE PRESSURE OR TEMPERATURE)

PM POWER MODULE (USED ONLY W/SYSTEM 350 COMPONENTS)

A319 THERMOSTAT FAN CYCLE CONTROL

MTB MOTOR TERMINAL BOARD

TB TERMINAL BOARD

CB CIRCUIT BREAKER

R RELAY

LEGEND

FAN MOTOR IDENTIFICATION

HEADER EN

D

M1

BOARD 1

TERMINAL

T1

T2

T3

3ÿ/60Hz

DISCONNECT

SWITCH

L1

L2

L3

L3

L1

L2

OPERATION MODE: Open Loop, Pulse Width Modulation

PRIORITY: Poti

PE

ALL MOTORS TO BE PROGRAMMED AS FOLLOWS:

L1

PE

L2

M2

L3

PE

M3

L1

L3

L2

L2

PE

L1

M4

L3

PE

L3

L1

M5

L2

F1

F5

F3

F4

F2

4

3

2

1

EBO

X

5

T2

TERMINAL

BOARD 2

T1

M5

7 - 0-10V PWM

1 - OUT

2 - GND

8 - GND

KL3

M4

7 - 0-10V PWM

1 - OUT

2 - GND

8 - GND

KL3

M3

7 - 0-10V PWM

1 - OUT

2 - GND

8 - GND

KL3

M2

7 - 0-10V PWM

1 - OUT

2 - GND

8 - GND

KL

3

M1

7 - 0-10V PWM

1 - OUT

2 - GND

8 - GND

KL

3

RED

BL

K

RE

D

BLK

RE

D

BLK

RE

D

BLK

BL

K

RED

P352PN

VDC

SENSOR

V

C

SN

24

0

C

O

M

TRANSFORMER

F13

SET P352PN INTEGRATION DIPSWITCH TO FAST

SET P352PN THROTTLING RANGE TO 100 PSI

SET P352PN MIN OUTPUT TO 0%

SET P352PN J1 FOR DIRECT ACTING CONTROL

Y350