21

Refrigeration Equipment Selection

General

When the hourly BTU load has been determined, equipment can

now be selected based on the information obtained in the initial

job survey. Some of the factors affecting equipment selection are:

1.

Equipment Balance

2.

Temperature Difference (T.D.)

3.

Capacity Control/Product Safety

4. Type of Operation/Air Flow

1. Equipment Balance

The condensing unit is generally selected first to have capacity

greater than the calculated cooling or freezing load. The

unit cooler(s) must be selected to balance the capacity of the

condensing unit.

The capacity of the condensing unit should be selected at a

suction temperature (after correction for suction line pressure

drop) which will balance with the unit cooler(s) at a desirable

T.D. between the refrigerant in the unit cooler and the air in the

refrigerated storage room. The condensing unit capacity must also

be selected at a condensing temperature corresponding to the

condensing medium (ambient air or water) temperature available

at the job location.

2. Temperature Difference

For Storage Rooms Above 32ºF. (0ºC.)

The nature of the product determines the desirable relative

humidity for the storage room. The desirable relative humidity,

in turn, dictates the approximate design T.D. between the air in

storage room and the refrigerant in the unit cooler.

For the general purpose cooler involving meats, vegetables, and

dairy products, it is common procedure to balance the low side

to the condensing unit at a 10ºF. to 12ºF. T.D.. It has been learned

by experience that if this is done, one may expect to maintain in

a cooler 80% to 85% relative humidity, which is a good range for

general storage.

Load Calculation Example 2 (page 8) involved the cooling and

storage of beef. The table shows that the recommended T.D.

is approximately 10ºF. Since the calculated load per hour based

on 16 hr. of condensing unit operation was 12696 BTU/hr., the

condensing unit to be selected should have a greater capacity

than 12696 BTU/hr. based on a suction temperature of +23ºF.

(10ºF. T.D. plus 2ºF. allowance for suction line pressure drop).

The unit cooler to be selected should have a minimum base

capacity (BTU/º T.D.) of 12696/10º T.D. or 1270 BTU/º T.D./hr. to be

sure that the unit cooler is large enough to balance properly with

the condensing unit.

Low relative humidity requirements permit higher T.D. which in

turn will allow selection of unit coolers with small base ratings

(BTU/hr./º T.D.)

For Storage Rooms Below 32ºF. (0ºC.)

In low temperature rooms the amount of dehydration of

unwrapped products is proportional to the T.D. Since the

prevention of excess dehydration is important and since low

temperature condensing unit capacities drop off sharply as the

suction temperature reduced, it is considered good practice to use

a maximum T.D. of 10ºF.

T.D.’s can be approximated by dividing the unit cooler capacity at

a 1º T.D. into the condensing unit capacity at the desired saturated

suction temperature (S.S.T.) for example:

Condensing Unit Capacity at S.S.T. = T.D.

Evaporating Capacity at 1º T.D.

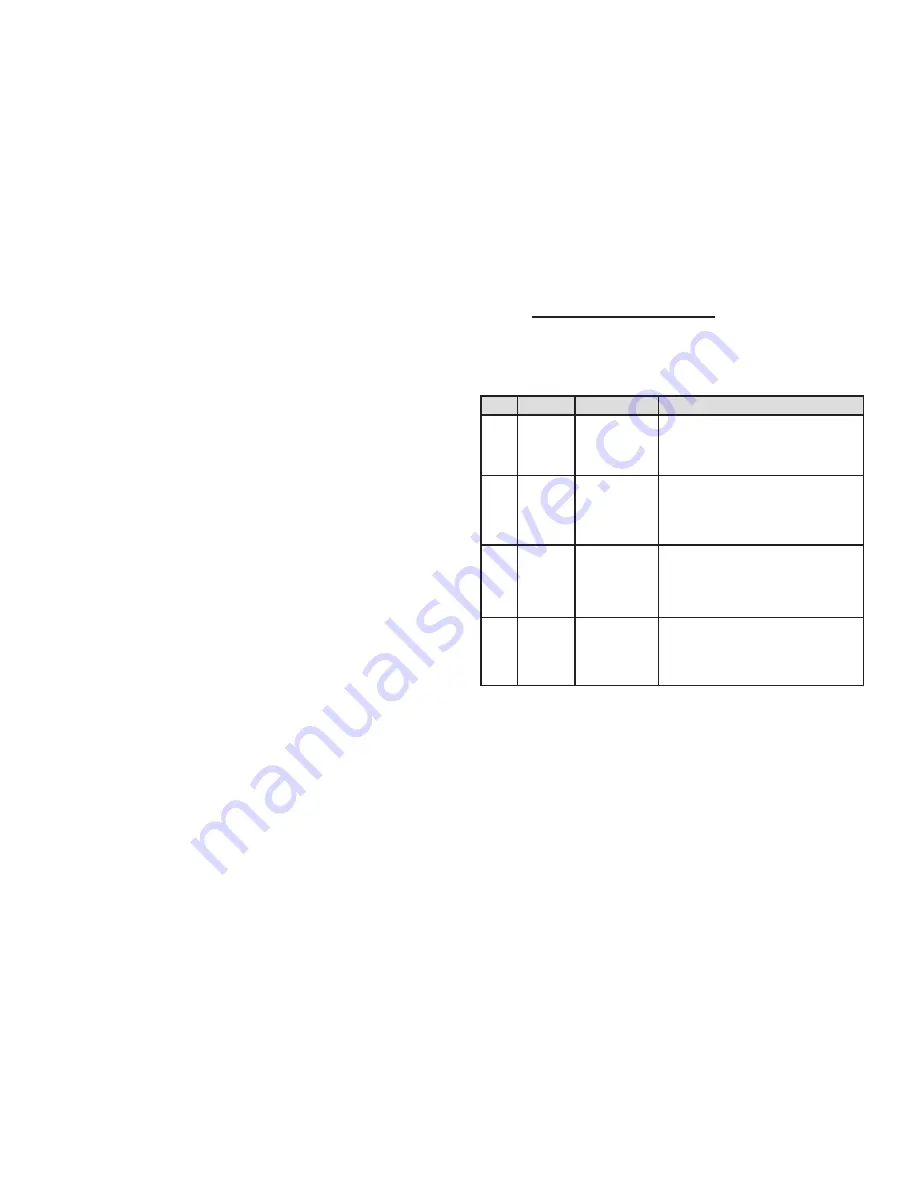

Class

T.D.

Approx. RH

Description of Product Classes

1

7º - 9ºF.

90%

Results in a minimum amount of moisture

evaporation during storage. Includes

vegetables, produce, flowers,

unpackaged ice and chill rooms.

2

10º - 12ºF.

80 - 85%

Includes general storage & convenience

store coolers, packaged meats and

vegetables, fruits and similar products.

Products require slightly lower relative

humidity levels than those in Class I.

3

12º - 16ºF.

65 - 80%

Includes beer, wine, pharmaceuticals,

potatoes and onions, tough skin fruits

such as melons & short term packaged

products. These products require only

moderate relative humidity.

4

17º - 22ºF.

50 - 65%

Includes prep and cutting rooms, beer

warehouses, candy or film storage and

loading docks. These applications need

only low relative humidities or are

unaffected by humidity.

Recommended Temperature Differences (T.D.)

for Four Classes of Foods (Forced Air Unit Coolers)

3. Product Safety/Capacity Control

In large boxes, it is recommended that the load be divided among

multiple units. A load that requires more than a 10 HP unit should

be split to provide the customer with some refrigeration level in the

event of mechanical failure. In addition, as refrigeration is selected

for the 1% worst occurrence of the year, multiple units provide for

some capacity control. In low load situations some units can be

turned off and the box maintained adequately with a fraction of

the horsepower necessary for the summer operation. Multiple units

on staged start up also cut the demand charges assessed by the

utility company which cut your customer’s electric bill.