23

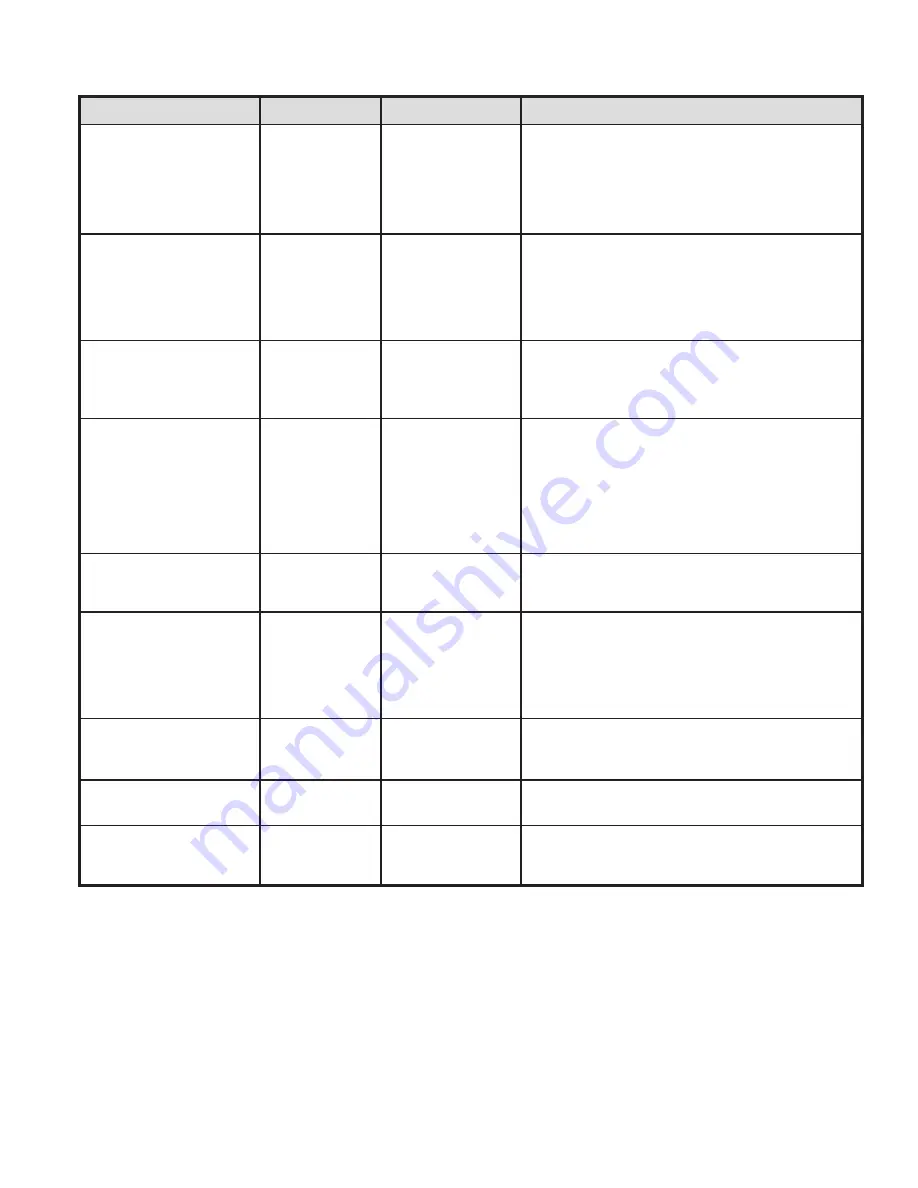

Application

T.D.

Coil

Notes

Convenience Store

10 - 15ºF.

Low Silhouette

Multiple units for adequate air coverage

Up to 18’ long = 1 coil

Up to 30’ long = 2 coils

Up to 40’ long = 3 coils

Estimating guide: Cooler 100 SF/ton*

Freezer 75 SF/ton*

Holding Warehouse

10 - 15ºF.

Medium or

Forklift Operation

Heavy Duty

Average air changes

Product load 10 - 15% of total load

Estimating guide: 200 - 300 SF/ton

Produce Warehouse

7 -10ºF.

Low Velocity

High seasonal loads

Medium

Heavy product respiration

or Heavy Duty

Additional humidity may be required

Estimating guide: 150 - 200 SF/ton

Blast Cooler or Freezer

7 - 10ºF.

Heavy Duty

High air velocity, heavy infiltration

Fast defrost (4-6 FPI coils)

Product spaced to allow air circulation

Equipment sized to extract all interior heat

Box temp below desired product temperature

Multiple units to provide capacity control

1.5 safety factor sometimes applied to handle

initial high rate of product heat evolution

Ice Cream Hardening

10ºF.

Heavy Duty

10 hour pull down with product 30% frozen and a

certain percentage over run

(thickness of ice cream)

Controlled Temperature

15 - 20ºF.

Heavy Duty

Floating box temperature (40-72ºF.) contingent on

Beer Warehouse

average monthly dew point

Auxiliary air circulation may be required due to

high T.D.

Heavy loading - high infiltration

20 - 30ºF. pull down on beer

Candy Warehouse

20 - 25ºF.

Heavy Duty

Low relative humidity

Auxiliary air circulation and reheat may be required

Vapor barrier essential

Prep Room

20ºF.

Low Velocity

Heavy motor and personnel load

Estimating guide: 150 SF/ton

Floral Box

8ºF.

Low Velocity

Light loading conditions

Glass Walls

Estimating guide 100 SF/ton*

General Guidelines

SF = Floor Square Foot ton = 12,000 BTUH

Note: Estimating guide ball park figures only. All attempts should

be made to obtain accurate job survey and subsequent refrigeration

calculations.

* Glass doors assumed on one long wall only