25

Line Sizing

The following Tables 22 through 24A on pages 25 through 30

indicate liquid lines and suction lines for all condensing units

for R-22, R-404A, R-134a, and R-507.

When determining the refrigerant line length, be sure to add an

allowance for fittings. See Table 26 on page 31. Total equivalent

length of refrigerant lines is the sum of the actual linear footage

and the allowance for fittings.

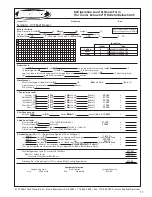

Table 22. Recommended Line Sizes for R-134a *

SUCTION LINE SIZE

SUCTION TEMPERATURE

SYSTEM

+40˚F

+30˚F

+20˚F

CAPACITY

Equivalent Lengths

Equivalent Lengths

Equivalent Lengths

BTU/H

25'

50'

75'

100'

150'

200'

25'

50'

75'

100'

150'

200'

25'

50'

75'

100' 150'

200'

1,000

3/8

3/8

3/8

3/8

3/8

1/2

3/8

3/8

3/8

3/8

1/2

1/2

3/8

1/2

1/2

1/2

1/2

5/8

3,000

3/8

1/2

1/2

1/2

5/8

5/8

1/2

1/2

1/2

5/8

5/8

5/8

1/2

5/8

5/8

7/8

7/8

7/8

4,000

1/2

1/2

5/8

5/8

5/8

5/8

1/2

1/2

5/8

5/8

5/8

7/8

5/8

5/8

7/8

7/8

7/8

7/8

6,000

1/2

5/8

5/8

5/8

7/8

7/8

1/2

5/8

5/8

7/8

7/8

7/8

5/8

5/8

7/8

7/8

7/8

7/8

9,000

5/8

5/8

7/8

7/8

7/8

7/8

5/8

7/8

7/8

7/8

7/8

7/8

5/8

7/8

7/8

7/8

7/8

1 1/8

12,000

5/8

7/8

7/8

7/8

7/8

7/8

7/8

7/8

7/8

7/8

1 1/8

1 1/8

7/8

7/8

7/8

1 1/8 1 1/8 1 1/8

15,000

7/8

7/8

7/8

7/8

1 1/8

1 1/8

7/8

7/8

7/8

1 1/8

1 1/8

1 1/8

7/8

7/8

7/8

1 1/8 1 1/8 1 1/8

18,000

7/8

7/8

7/8

7/8

1 1/8

1 1/8

7/8

7/8

1 1/8

1 1/8

1 1/8

1 1/8

7/8

7/8

1 1/8 1 1/8 1 1/8 1 3/8

24,000

7/8

7/8

1 1/8

1 1/8

1 1/8

1 1/8

7/8

1 1/8 1 1/8

1 1/8

1 3/8

1 3/8

7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8

30,000

7/8

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

7/8

1 1/8 1 1/8

1 3/8

1 3/8

1 3/8

1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8

36,000

7/8

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

1 1/8

1 1/8 1 3/8

1 3/8

1 3/8

1 5/8

1 1/8 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8

42,000

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 1/8

1 1/8 1 3/8

1 3/8

1 5/8

1 5/8

1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8

48,000

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 5/8

1 1/8

1 3/8 1 3/8

1 3/8

1 5/8

1 5/8

1 1/8 1 3/8 1 5/8 1 5/8 1 5/8 1 5/8

54,000

1 1/8

1 1/8

1 3/8

1 3/8

1 5/8

1 5/8

1 1/8

1 3/8 1 3/8

1 5/8

1 5/8

1 5/8

1 1/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8

60,000

1 1/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 1/8

1 3/8 1 3/8

1 5/8

1 5/8

2 1/8

1 3/8 1 3/8 1 5/8 1 5/8 2 1/8 2 1/8

66,000

1 1/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 3/8

1 3/8 1 5/8

1 5/8

2 1/8

2 1/8

1 3/8 1 5/8 1 5/8 1 5/8 2 1/8 2 1/8

72,000

1 1/8

1 3/8

1 5/8

1 5/8

1 5/8

2 1/8

1 3/8

1 3/8 1 5/8

1 5/8

2 1/8

2 1/8

1 3/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8

78,000

1 1/8

1 3/8

1 5/8

1 5/8

1 5/8

2 1/8

1 3/8

1 5/8 1 5/8

1 5/8

2 1/8

2 1/8

1 3/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8

84,000

1 3/8

1 3/8

1 5/8

1 5/8

2 1/8

2 1/8

1 3/8

1 5/8 1 5/8

2 1/8

2 1/8

2 1/8

1 3/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8

90,000

1 3/8

1 3/8

1 5/8

1 5/8

2 1/8

2 1/8

1 3/8

1 5/8 1 5/8

2 1/8

2 1/8

2 1/8

1 3/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8

120,000

1 3/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

1 5/8

1 5/8 2 1/8

2 1/8

2 1/8

2 5/8

1 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8

150,000

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

1 5/8

2 1/8 2 1/8

2 1/8

2 5/8

2 5/8

2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 2 5/8

180,000

1 5/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

1 5/8

2 1/8 2 1/8

2 5/8

2 5/8

2 5/8

2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8

210,000

1 5/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 1/8

2 1/8 2 5/8

2 5/8

2 5/8

3 1/8

2 1/8 2 1/8 2 5/8 2 5/8 3 1/8 3 1/8

240,000

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 1/8

2 1/8 2 5/8

2 5/8

2 5/8

3 1/8

2 1/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8

300,000

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

3 1/8

2 1/8

2 5/8 2 5/8

2 5/8

3 1/8

3 1/8

2 1/8 2 5/8 3 1/8 3 1/8 3 1/8 3 5/8

360,000

2 1/8

2 5/8

2 5/8

2 5/8

3 1/8

3 1/8

2 1/8

2 5/8 2 5/8

3 1/8

3 1/8

3 5/8

2 5/8 3 1/8 3 5/8 3 5/8 4 1/8 4 1/8

480,000

2 5/8

2 5/8

3 1/8

3 18

3 1/8

3 5/8

2 5/8

3 1/8 3 1/8

3 1/8

3 5/8

3 5/8

3 1/8 3 5/8 3 5/8 4 1/8 5 1/8 5 1/8

600,000

2 5/8

3 1/8

3 1/8

3 1/8

3 5/8

3 5/8

2 5/8

3 1/8 3 1/8

3 5/8

3 5/8

4 1/8

3 1/8 3 5/8 4 1/8 4 1/8 5 1/8 5 1/8

* NOTES:

1. Sizes that are highlighted indicate maximum suction line sizes that should be used for risers. Riser size should not exceed horizontal size.

Properly placed suction traps must also be used for adequate oil return.

All sizes shown are for O.D. Type L copper tubing.

2. Suction line sizes selected at pressure drop equivalent to 2˚F. Reduce estimate of system capacity accordingly.

3. Recommended liquid line size may increase with reverse cycle hot gas systems.

4. Consult factory for R-134a operation at winter conditions below 0° ambient.

Heated and insulated receiver required below 0° ambient.

If system load drops below 40% of design, consideration to installing double suction risers should be made.