4

Job Survey

The person involved in a heat transfer calculation needs

information in order to predict accurately the heat load on a

refrigerated structure. The more complete the information, the

better the calculation. Good calculations are the first step in

assuring adequate refrigeration equipment is selected for the

project.

The initial job survey should be as complete as possible and

include the following:

Design Ambient Temperature

This is the ambient surrounding the box necessary for the load

calculations. Another ambient to be considered on air cooled

projects is the one surrounding the condensing unit which will

affect equipment selection.

Storage Temperature and Humidity Requirements

Refrigeration equipment by its nature is a dehumidification

process. We try to minimize or maximize the drying effect of the

equipment by selecting the appropriate Temperature Difference

(T.D.) between the saturated suction temperature of the

evaporator and the room air. The T.D. selected approximates the

desired relative humidity (see page 21).

Dimensions, Insulation, Type of Construction,

Exposure

This criterion lends itself to well established, straight forward

calculations, but the information while elementary, is often

omitted from the initial job survey. Transmission load for 4”

Styrofoam is double the transmission load for 4” formed in place

urethane.

Infiltration or Air Changed Load

Heat, both sensible and latent, enters an enclosure through door

openings whenever the air surrounding the enclosure is warmer

than the box temperature. Knowing the location, size and

number of the door openings and the temperature to which they

are exposed will greatly aid in determining the heat load of the

infiltration air.

Product

1. Type - storage requirements

2. Weight

3. Entering temperature

4. Pull down time

Miscellaneous Loads

1. Lights

2. Motors including fan motors, fork lifts, conveyers

3. People

4. Glass doors

Operations

1. Holding cooler or freezer

2. Blast cooling or freezing

3. Preparation, processing or cutting rooms

4. Distribution warehouses

5. Reach-in or walk-in boxes

Unusual Conditions

Electrical Service and Type of Equipment Desired

While not directly affecting refrigeration load calculations,

this is essential in the job survey to select the proper equipment.

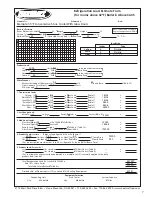

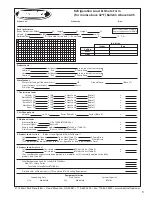

Refrigeration Load Calculations

With the initial survey complete, the heat load calculation is

separated into the following main sources of heat for a given 24

hour period:

1. Transmission load

2. Air change load

3. Miscellaneous load

4. Product load

Accuracy

Accuracy in calculation is the first step in having a satisfied

customer. There are short cuts, based on averages, that may

be taken and which must be used when the product load is

indefinite or unknown (see Quick Selection Guide on page 41

and the Rapid Load Calculator on page 43). But when all the data

necessary to calculate the four main sources of heat gain are

available, the complete calculation should be made.

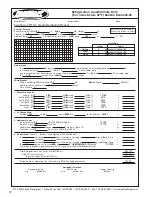

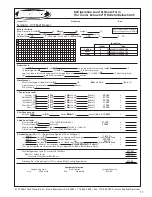

Quick Selection Chart for Small

and Medium Coolers and Freezers

The Quick Selection Guide on page 41 may be used for a quick

comparison of heat load figured on Bulletins Above32-05 or

Below32-05 or to obtain approximate heat loads for small and

medium sized boxes. The loads are shown for a 95ºF. outside

temperature.

Rapid Load Calculator for Large Coolers and Freezers

The Rapid Load Calculator on page 43 may be used for quick

approximations of the heat load in large boxes and for a

reasonable comparison of heat loads figured on Bulletins

Above32-05 or Below32-05. The Calculator graph on page 43 is

based on the following average daily product loadings for coolers

and freezers:

1. Transmission Load

Methods of determining the amount of heat flow through walls,

floor and ceiling are well established. This heat gain is directly

proportional to the Temperature Difference (T.D.) between the

two sides of the wall. The type and thickness of insulation used

in the wall construction, the outside area of the wall and the

T.D. between the two sides of the wall are the three factors

that establish the wall load. Tables are provided to simplify

the calculations (see Table 1, page 13). Some coolers for above

freezing temperatures have been constructed with only a floor

slab (no floor insulation). The factors shown in the wall heat gain

(Table 1) are based on a concrete floor slab and the T.D. between

the local ground temperature and the storage room temperature.

Average Daily

Average Daily

Volume-

Product Loads (lbs.)

Product Loads (lbs.)

Cu. Ft.

for Coolers

for Freezers

500 - 3,000

6,200 - 8,000

1,600 - 2,000

3,000 - 4,600

8,000 - 11,000

2,000 - 2,500

4,600 - 8,100

11,000 - 17,000

2,500 - 4,000

8,100 - 12,800

17,000 - 26,000

4,000 - 6,200

12,800 - 16,000

26,000 - 33,000

6,200 - 7,500

16,000 - 20,000

33,000 - 40,000

7,500 - 9,500

20,000 - 28,000

40,000 - 56,000

9,500 - 13,000

28,000 - 40,000

56,000 - 66,000

13,000 - 17,000

40,000 - 60,000

66,000 - 110,000

17,000 - 25,000

60,000 - 80,000

110,000 - 150,000

25,000 - 34,000

80,000 - up

150,000 - up

34,000 - up