42

Tips for Quick Selection Guide

Walk- In Cooler Box Load Parameter

1. 95ºF. ambient air temperature surrounding box.

2. 4” Styrene (R=16.7, K=0.24) walls/ceilling, 6” concrete slab floor.

3. Average product load with 5ºF. pull down in 24 hours.

4. BTUH load based on 16-18 hour compressor run time for 35ºF.

box (timer recommended) +20 hours for 30ºF. box.

5. See Table C for adjustment to box load for glass doors.

6. For 80ºF. ambient temp. surrounding box, deduct 12%.

7. For 4” Urethane walls+ceiling, 6” concrete slab floor deduct 12%.

8. For 10’ ceiling height add 10%.

9. For additional BTUH load for product cooling see Table A.

Walk-In Freezer Box Load Parameters

1. 95ºF. ambient air temperature surrounding box.

2. 4” Urethane (R=25, K=0.16) walls, c floor.

3. Average product load with 10 degree pull down in 24 hours.

4. BTUH load based on 18 hour compressor run time.

5. See Table C for adjustment to box load for glass doors.

6. For 80ºF. ambient air temp. surrounding box, deduct 12%.

7. For 20 hour compressor run time (light frost load) in lieu of 18

hour run time, deduct 11%

8. For 10’ ceiling height add 10%

9. For additional BTUH load for product freezing, refer to Table D

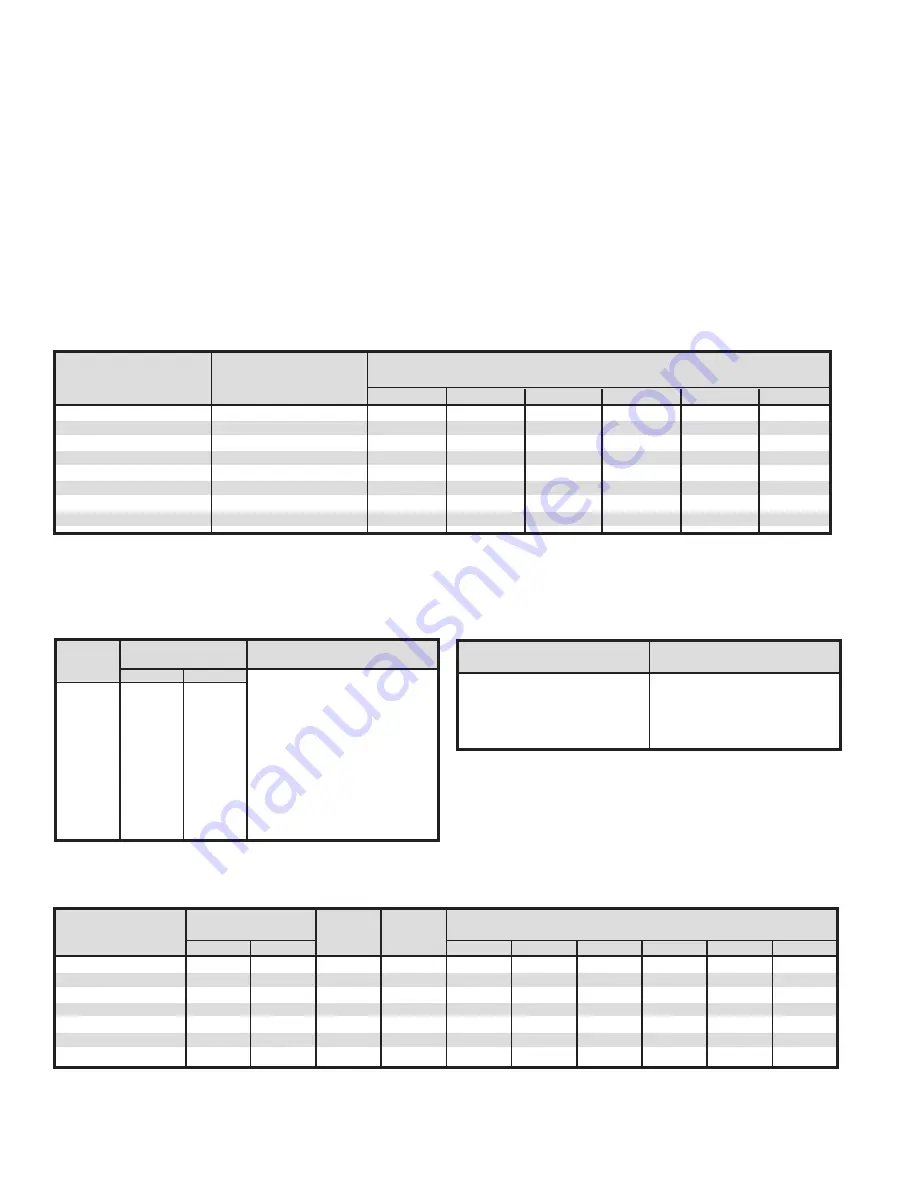

Specific Heat

10 Degree Pull down BTUH Load for Indicated

Product

Above lbs of Product per 24 Hours

Freezing

500

1000

1500

2000

3000

5000

Beef

0.72

240

480

720

960

1440

2400

Pork

0.53

177

353

530

706

1060

1767

Veal & Lamb

0.76

253

506

760

1012

1520

2533

Poultry

0.79

263

526

790

1053

1580

2633

Seafood

0.80

267

533

800

1066

1600

2667

Vegetables

0.92

307

613

920

1226

1840

3067

Bakery Food

0.74

247

494

740

988

1480

2467

Beer

1

333

666

1000

1333

2000

3333

Table A

Product Cooling Loads for Walk-In Coolers

(24 hour pull down/18 hour compressor operation) 24% safety factor added to loads to allow for service.

For product pull down greater than 10 degrees, divide pull down

temperature by 10. Multiply this number by the BTUH shown on

Table A, then add to Box Load

Floor

Approx. 65% R.H.

SQ FT

Room Temp.

55ºF.

50ºF.

100

93

105

200

88

99

300

85

95

400

81

90

500

78

87

600

75

85

700

72

81

800

69

78

900

67

75

1000

65

73

1200

62

69

Room Loads based on continuous

operation and includes allowance

for average number of personnel,

processing equipment, etc., with

glass panel in one wall and walls

and ceiling insulated with 3” of

styrene with box located in air

conditioned area. Evaporator

should be low outlet velocity type

to avoid drafts and should be

selected for continuous operation

and not less than 30ºF. evap. temp.

Table B

Meat Cutting/Prep Room Load

(BTU/HR/SQ FT of floor area)

Table C

Glass Door Loads

Box

BTU per

Temperature

Door

+35

1060

+30

960

0

1730

-10

1730

-20

1730

* Adjusted for 16-18 hour run time. Multiply number of doors

times door load above and add to box load.

Spec. Heat

Latent

Freezer

Product BTU/lb/Deg. F. Heat

Temp. -10ºF. Freezer Temperature BTUH for Indicated lbs. Prod/Day

32 +

32 -

BTU/lb.

(F)

100

300

750

1000

1500

3000

Beef

0.72

0.40

95

29

790

2370

5925

7900

11850

23700

Pork

0.53

0.32

60

28

523

1571

3926

5235

7853

15710

Veal & Lamb

0.76

0.45

100

28

841

2524

6311

8414

12621

25240

Poultry

0.79

0.42

106

27

878

2636

6590

8787

13181

26360

Seafood

0.80

0.43

110

28

906

2719

6797

9063

13595

27190

Vegetables

0.92

0.47

130

30

1053

3159

7898

10530

15795

31590

Bakery Foods

0.74

0.34

53

20

520

1560

3900

5200

7800

15600

Table D

Product Freezing Loads for Walk-In Freezers

Freezing loads based on product entering at 40ºF. maximum.

For a specific pull down time, the product load BTU/hr. may be

adjusted by multiplying the above loads by 24 and dividing by

the specific pull down time in hours. To adjust for 0ºF. freezer

temperature, multiply the above loads by 0.97, and for -20ºF.

freezer, multiply by 1.04.