43

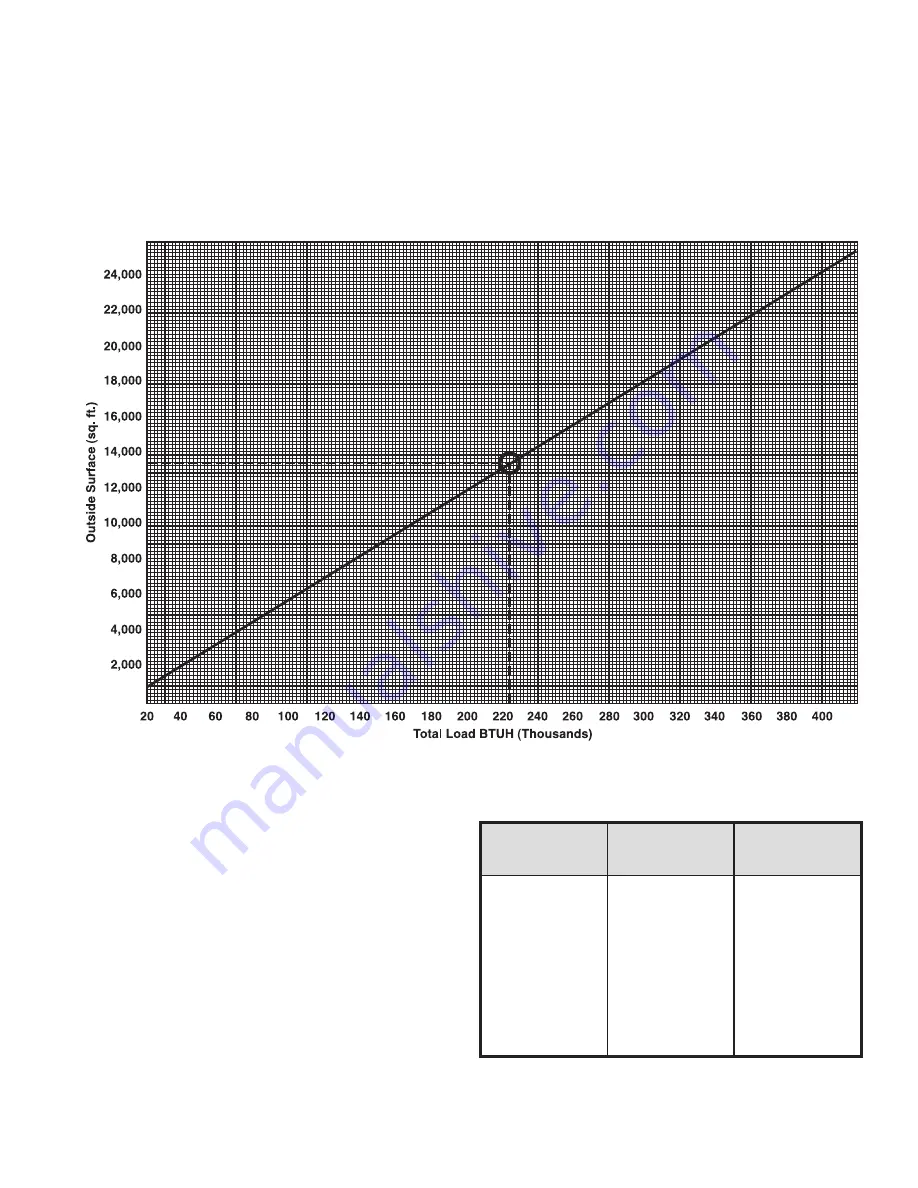

Rapid Load Calculator for Large Coolers and Freezers

Design Conditions: 95ºF. ambient; heavy

service; 16-hr. compressor running time;

average number of lights, motors, and

people; product load figured according

to accompanying table; product traffic

calculated at 30 degree temperature

reduction for coolers, 10 degree

temperature reduction for freezers.

Note: This calculator will work equally well

for coolers and freezers, providing the room

is insulated as indicated below:

35ºF. cooler- 3”

polystyrene or equivalent

30ºF. cooler- 4”

polystyrene or equivalent

0ºF. cooler- 5”

polystyrene or equivalent

-10ºF. cooler- 5 1/2” polystyrene or equivalent

-20ºF. cooler- 6”

polystyrene or equivalent

Example: 100 x 40 x 20’ zero ºF. freezer.

Outside surface totals 13,600 sq. ft. Find

13,600 sq. ft. outside surface line at left

of graph. Follow it across to the straight

line curve. Then drop down to total load

line at bottom of graph. Total load for this

example is 224,000 BTUH. Select equipment

accordingly.

Material originated by Hugo Smith, consulting editor, Air

Conditioning and Refrigeration Business. Reprinted by permission

from the April 1968 issue of Air Conditioning and Refrigeration

Business. Copyright by Industrial Publishing Co., Division of Pittway

Corporation.

Average Daily

Average Daily

Volume-

Product Loads (lbs.)

Product Loads (lbs.)

Cu. Ft.

for Coolers

for Freezers

500 - 3,000

6,200 - 8,000

1,600 - 2,000

3,000 - 4,600

8,000 - 11,000

2,000 - 2,500

4,600 - 8,100

11,000 - 17,000

2,500 - 4,000

8,100 - 12,800

17,000 - 26,000

4,000 - 6,200

12,800 - 16,000

26,000 - 33,000

6,200 - 7,500

16,000 - 20,000

33,000 - 40,000

7,500 - 9,500

20,000 - 28,000

40,000 - 56,000

9,500 - 13,000

28,000 - 40,000

56,000 - 66,000

13,000 - 17,000

40,000 - 60,000

66,000 - 110,000

17,000 - 25,000

60,000 - 80,000

110,000 - 150,000

25,000 - 34,000

80,000 - up

150,000 - up

34,000 - up