11

PRO

3

Top Mount Packaged Refrigeration System | Outdoor

Programming the PJEZC Carel

Electronic Controller

Reprinted with permission from Carel.

The Carel PJEZC control is a fully configurable electronic

refrigeration controller. The Top Mount packaged

refrigeration system uses the Carel controller on all three

temperature designated models. The models differ by

a pre-programmed parameter list that is specific for

each application.

There are two levels of programming with the C controller.

The first level can be accessed through the keypad. Set

Point (st), Interval between defrost (do), Maximum Defrost

Duration (dP), and Dripping Time (dd) are examples of first

level parameters. Second level parameters can be accessed by

entering a password. See “Modifying Parameters” (page 17).

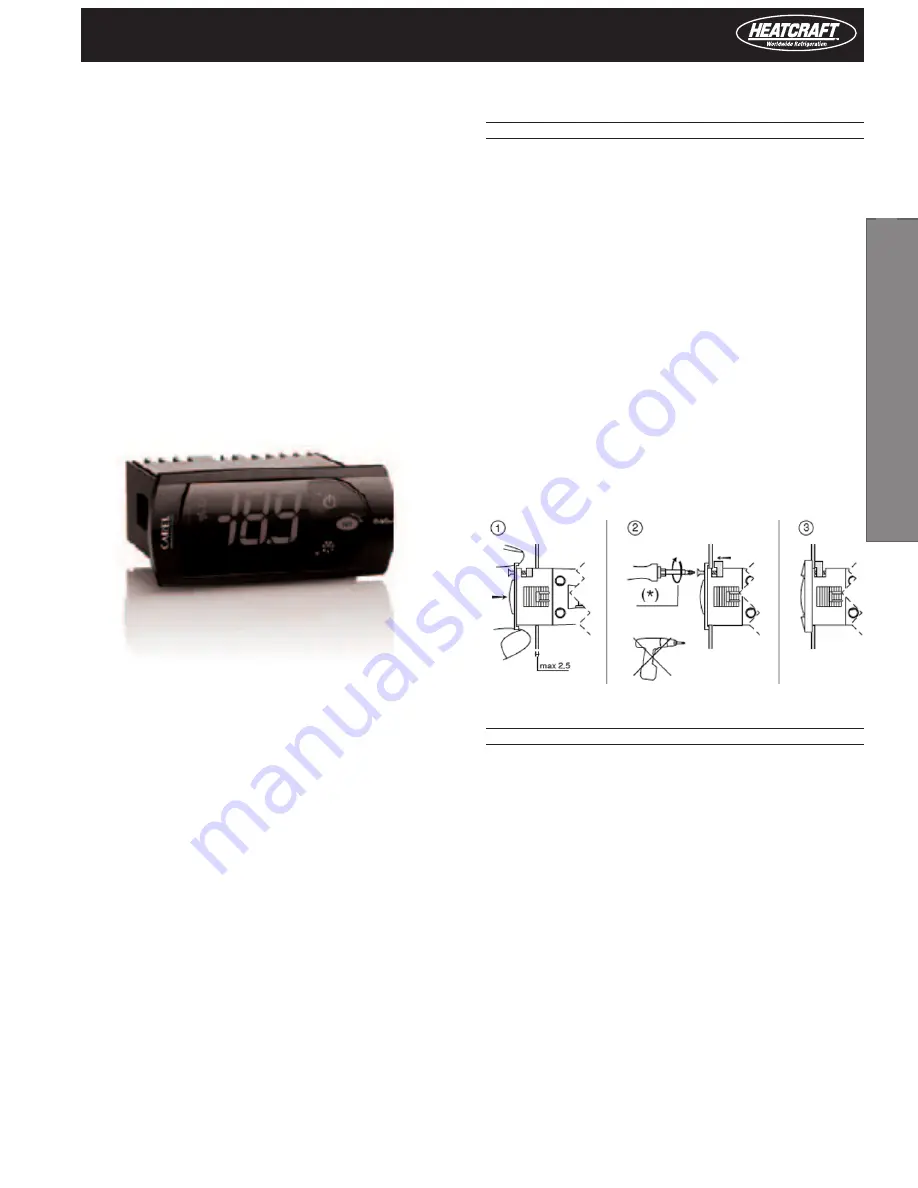

Installation and Removal

PANEL INSTALLATION FROM THE FRONT USING SCREWS

• The thickness of the fastening panel must not exceed 3 mm;

• Remove the front frame and make sure that the two catches

are in place (these must not protrude from the outline of the

drilling template). If necessary, unscrew the two screws. Do not

unscrew excessively, the screws must not be detached from the

front panel (phase 1);

• Insert the instrument in the opening in the panel and hold it in

position by the centre of the front panel (phase 1);

• Using the screwdriver, tighten the bottom screw 90°, the catch

must come out of its slot and click onto the panel, then tighten

until the front panel is secure; Do not over-tighten, when the

front panel is secured blocks simply make another ½ turn to

compress the gasket; If the catch does not click onto the panel,

unscrew the screw, applying pressure at the same time with

the screwdriver so that the catch moves back. Do not unscrew

too much, the head of the screw must not be raised from the

surface of the front panel (phase 2);

• Repeat the same operation for the top screw (phase 2);

• Apply the front frame (phase 3).

DISMANTLING USING THE SCREWS FROM THE FRONT

• Unclip the front frame;

• Unscrew the bottom screw, at the moment the front panel

detaches from the panel keep pressure on the screw and

unscrew a further 90° to make the catch go back into its slot;

• Repeat for the top screw;

• Remove the instrument from panel, keeping it horizontal

* Do not over-tighten the screws.

3.

C

on

tr

ollers