6

Installation and Operations Manual

1.

O

wner's

O

per

ating

Instr

uc

tions

The Outdoor

comes standard with the

following additional components:

• Crankcase Heater

• Drain Line Heater

• Weather Hood

• Fan Cycling

(Pressure on 1 fan models, Pressure and Ambient

on 2 fan models).

Standard Installation Procedure

PTT Models

For outdoor use

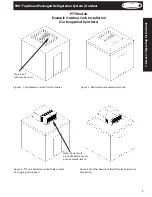

1. Provide a 25" X 25" (medium cabinet) or

25" X 38.5" (large cabinet) opening in the

roof of walk-in cooler or as specified by the

panel manufacturer.

2. Apply silicone caulk around the perimeter of roof

opening. Place the curb on roof of cooler. It is

recommended that the curb be fastened to

the roof panels using non-conductive bolts or

insulating the bolt heads. Bolt heads should be

countersunk or low profile to prevent contact with

the

system. (See Figure 1, page 7) Check the

top of the curb with a level.

units require

a surface that is within 1° of level or better and no

more than a 5/8" drop per 3 feet

(17mm drop per meter).

3. Install the membrane onto the roof of the box and

over the curb. Fasten to roof per panel

manufacturer's instructions. The membrane

material should be slit over the evaporator grill

opening the flaps allowed to drape into the hole

2" - 4". (See Figure 2, page 7) Care should be taken

during the membrane installation to prevent

bunching or folding which could affect the gasket-

to-curb sealing or trap rainwater adjacent to the

curb.

4. Remove the weather hood from the

system.

The compressor compartment cover(s) should be

left in place during lifting/rigging.

5. Place

system onto curbing and center over

opening in roof box. (See Figure 3, page 7)

6. It is recommended that the

system be

secured to the curb with wood screws. Seal

the screw heads as necessary to prevent

moisture from entering beneath the membrane.

Additional caulk may be applied around the

perimeter of the evaporator box gasket. The

compressor compartment should not be caulked.

7. Install trim pieces (if used) around the ceiling

opening in cooler.

General Safety information:

Do NOT lift the

by the weather hood.

This product is not designed to be transported while

installed or operating.

8. Remove compressor compartment cover for

access to electrical box.

9. Connect power wiring in accordance with all

applicable building and electrical codes.

10. Reinstall condensing unit cover(s).

11. Reinstall the protective weather hood.

(See Figure 4, page 7)

12. Apply power and check for proper operation.

Condensate Drain

Outlet Location

Drain Line

A condensate drain outlet is located on the side of the

compressor compartment. Field piping may be connected

to the outlet provided it is adequately sloped and heated

for freezing weather conditions. There is a drain line "P" trap

located in the PTT unit.