PRO

3

Side Mount Packaged Refrigeration System Installation and Operations Manual, May 008

13

PRO

3

Side Mount Packaged Refrigeration System

N.C.

Line

8(3)A250V

~

1 2 3 4 5

6

6

9 10 11 12

5(

1)

A

Max

20A

Comp

Def

Ev

ap

.

R

oo

m

7

Hot Key/IV probe

TTL or. X-REP output

Fan

8

20(8)A250V

~

N.C.

Line

8(3)A250V

~

1 2 3 4 5

6

6

9 10 11 12

8(3)A

Max

16A

Comp

Def

Fan

Ev

ap

.

R

oo

m

7

Hot Key/IV probe/

TTL or X-REP output

NOTE: The compressor relay is 8(3)A or 16(6)A according to the model.

20A comp. relay - 230 vAC

Service Information

All PRO

3

packaged refrigeration system units are designed for

maximum durability, reliability and simplicity. The PRO

3

packaged

refrigeration system comes to you ready for operation, fully charged

and with all controls preset at the factory. The following information

is provided as an aid in the event that service is required.

Maintenance

The evaporator section of a PRO

3

packaged refrigeration system

should be checked at least once for proper defrosting because the

amount and pattern of frosting can vary greatly.

The frost build-up is dependent on the temperature of the room,

the type of product being stored, how often new product is brought

into the room and percentage of time the door to the room is open.

It may be necessary to periodically change the number of defrost

cycles or adjust the duration of defrost.

System Standard Maintenance guidelines

After first year of operation and under normal usage, maintenance

should cover the following items at least once every six months:

1. Check and tighten ALL electrical connections.

. Check all wiring and insulators.

3. Check contactors for proper operation and for worn contact

points.

4. Check all fan motors. Tighten motor mount bolts/ nuts and

tighten fan set screws.

5. Clean the condenser coil surface.

6. Check the operation of the control system. Make certain all

safety controls are operating properly.

7. Check all defrost controls for proper function.

8. Clean the evaporator coil surface.

9. Clean the drain pan and check the drain pan and drain line for

proper drainage.

CAUTION: Unit is critically charged, care must be taken

not to reduce the system refrigerant charge while

taking pressure readings. Technician must compensate

for any refrigerant that might escape the unit into the

gauge tubing.

Connections

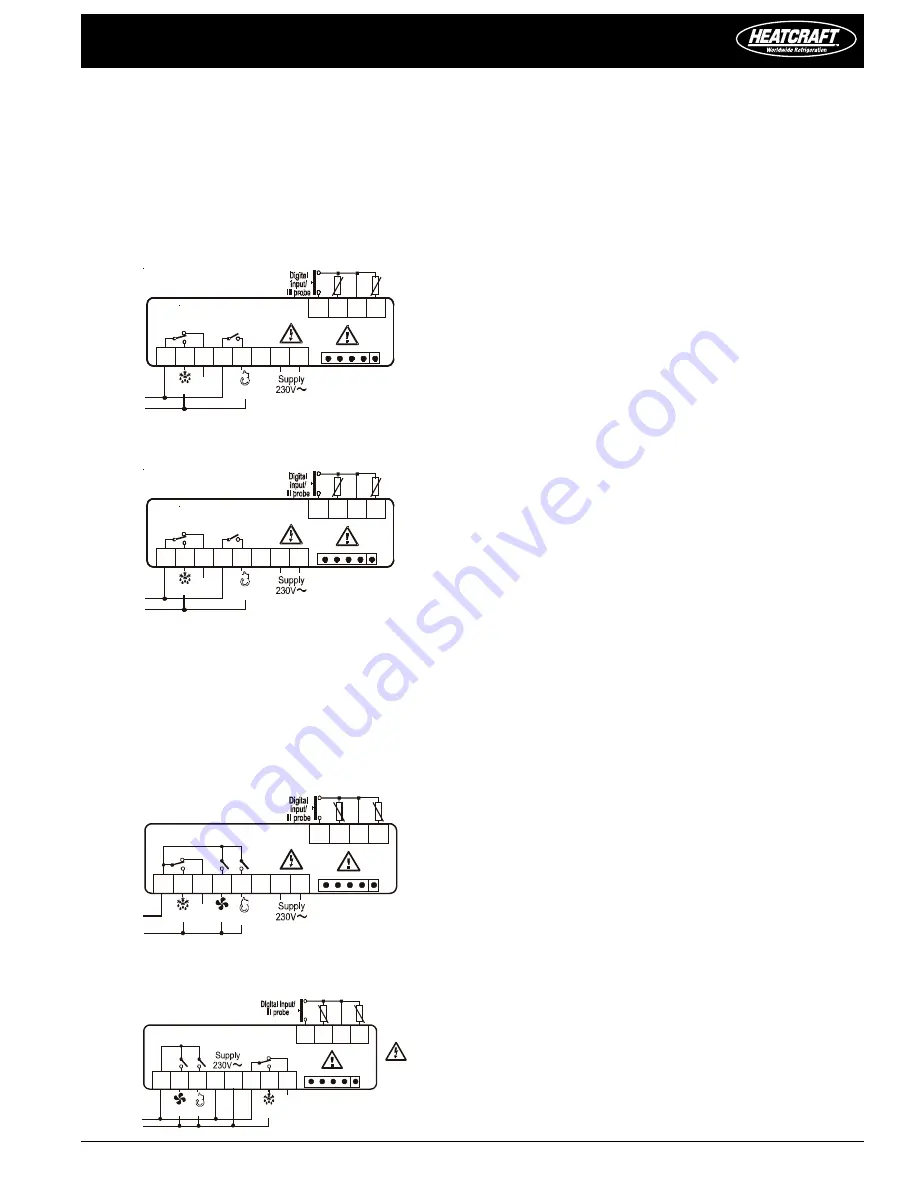

XR40CX

The X-REP output excludes the TTL output. It’s present in the

following codes: XR40CX- xxxx, XR40CX –xx3xx; XR40CX –xx6xx;

XR40CX –xx7xx;

The digital input configurable as third probe is present in the

following codes: XR40CX- xx4xx, XR40CX –xx5xx; XR40CX –xx6xx;

XR40CX –xx7xx;

8A compressor

N.C.

1

3

4

5

6

7

9 1 0 1 1 1

Comp

Def

Ev

ap

.

R

oo

m

8

Hot Key/IV Probe

TTL or X-REPoutput

8(3)A250V

8(3)A250V

Line

20A compressor

N.C.

1

3

4

5

6

7

9 1 0 1 1 1

Comp

Def

Ev

ap

.

R

oo

m

8

Hot Key/IV probe

TTL or X-REP output

8(3)A250V

20(8)A250V

Line

XR60CX

The X-REP output excludes the TTL output. It’s present in the

following codes: XR60CX- xxxx, XR60CX –xx3xx; XR60CX –xx6xx;

XR60CX –xx7xx;

The digital input configurable as third probe is present in the

following codes: XR60CX- xx4xx, XR60CX –xx5xx; XR60CX –xx6xx;

XR60CX –xx7xx;

8A or 16A comp. relay - 230 vAC