60

ELECTRONICS

Controller

Principles of the Controller

The 400-4S controls the burn of the stove by monitoring the firebox thermocouples temperatures and giving

more or less primary to the burn chamber depending on those temperatures. It has two burn modes, “Normal”

and “Boost”. The 400-4S will run in “Normal” mode most of the time. The only times it will switch to Boost

would be if the user went to the controller and pressed the boost button, or the water temperature falls 10

degrees below the restart temperature. At that point the fan will turn to high speed and the BTU output will

increase. Boost mode will be reset when the stove reaches the 185 water temperature limit and cycles. On

restart the stove will run in normal mode.

The light switch on the inside of the front of the stove is used to turn off the fan and turn on the light in the

front. When the switch is flipped up, the front light will turn on and the powered flipper(solenoid) will open up.

The solenoid/flipper opens up to help give some air to the firebox while a fire is being started. The powered

flipper(solenoid) will close if the light is on for more than 10 minutes. When the switch is closed, the fan will

turn on and the primary/secondary motor will be set to the initial loading setting. The 400-4S is considered

“Loaded” when the light switch is flipped up then down. This should be done every time the stove is loaded to

ensure proper startup.

When the front door is opened, and the stove is in its off cycle the Automatic Fan Switch will cause the fan to

run. The user should wait approximately 1 minute from opening the outer door to opening the inner door to

allow for the volatile smoke to be cleared out of the firebox. If the front door is left open, the stove will continue

to run until the water temp hits the high limit(200F). When the front door is closed, it will run until the stove hits

the 185 water temperature limit and then will shut down.

Pressing F1 will bring up the main screen with the boost and Load buttons. Pressing F2 will bring up a screen

that will show the firebox thermocouple temperatures, the fan speed percent and the primary/secondary motor

percent. This screen will be helpful if problems arise on the stove. F3 will bring up a screen that will tell you

if any firebox thermocouple probes are not reading or if the thermocouple block isn’t reading. Pressing F4 will

bring up the start screen which shows the Program version number and the serial number of the stove.

CHAPTER 19

Summary of Contents for 400-4S

Page 1: ...Outdoor Furnaces TM SAVE THESE INSTRUCTIONS...

Page 10: ...5 HEATMOR Stainless Steel Outdoor Furnace Model 400 4S Chapter 1...

Page 73: ...68...

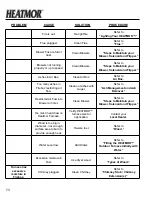

Page 88: ...83 PROBLEM CAUSE SOLUTION PROCEDURE...

Page 92: ...87 Outdoor Furnaces...

Page 93: ...88 NOTES...

Page 94: ...89 wiring diagram...

Page 95: ...90 Revised Manual on 07 11 12...