12

Revised 2019

MAINTENANCE & CLEANING

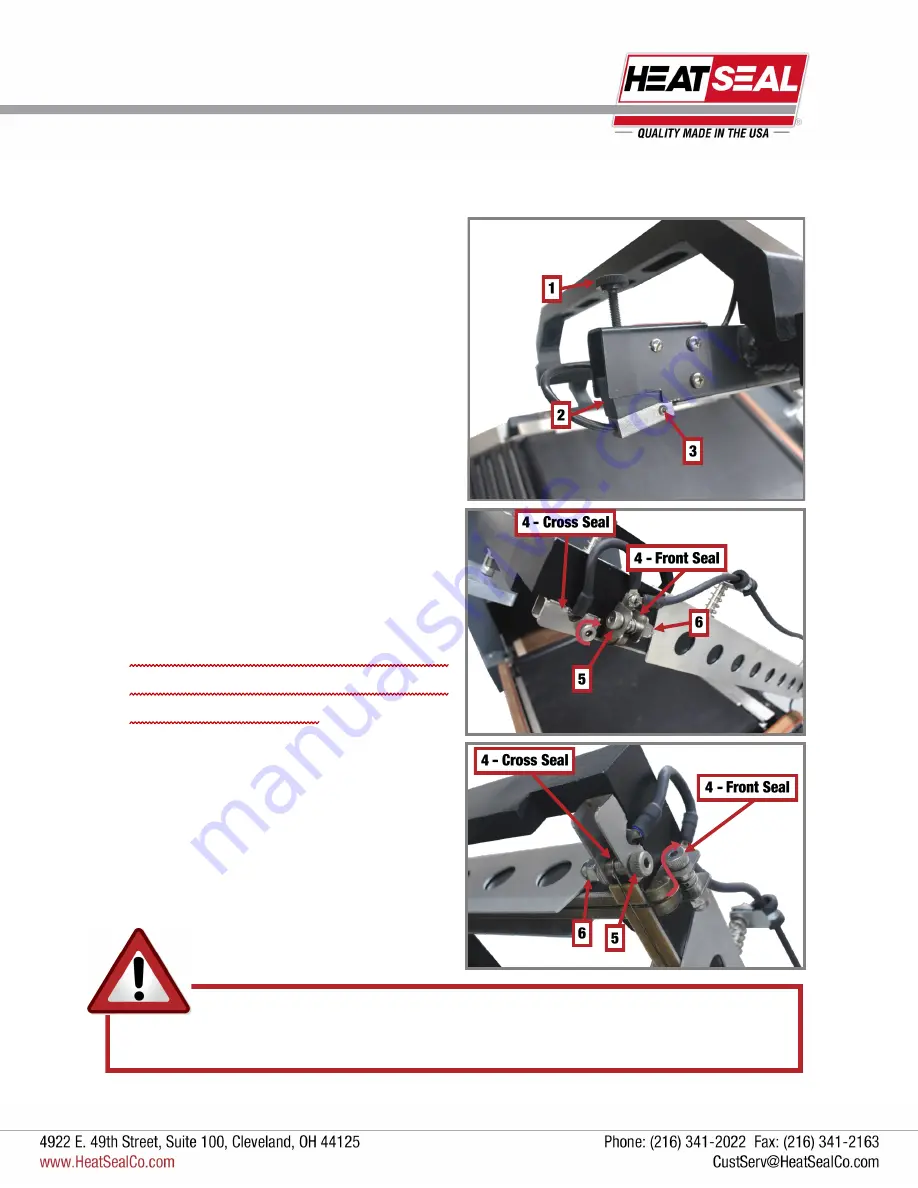

SERVICING THE SEALING WIRES

TO REMOVE WIRES

Tighten the knob (1) on the tension block (2) to relieve the

sealing wire tension.

Using a small screwdriver, loosen the screw (3) in the side

of the tension block and pull out the sealing wire.

Loosen the screw (5) at the other end where the wires

cross and remove the sealing wire.

TO REPLACE WIRES

Insert the new wire in the tension block (2) and re-tighten

the screw (1).

Then, insert the other end of the wire into the hole on the

tensioning screw (4) leaving the wire loose.

Use a 1/8” Allen Key on the screw head (5), and a 3/8”

wrench on the lock nut (6) to tighten the wire Clockwise.

The wire will wind around the screw body Clockwise until

the ideal tension is met.

WIRE MUST WRAP AROUND TENSION

BOLT 2.5-3 TIMES TO ENSURE

PROPER GROUNDING.

** Tensioning the wire Clockwise around the tensioning

screw will provide longevity to the sealing wires. **

COMPLETELY LOOSEN BOTH KNOBS ON THE TENSION BLOCKS BEFORE

TESTING THE SEALER. IF THE WIRES ARE LOOSE WHEN COOL, FOLLOW THE

REPLACEMENT STEPS ABOVE TO RETENSION WIRES.

Summary of Contents for HSE-100

Page 15: ...15 Revised 2019...