MUL

TIPOINT

3

3

1.0 IMPORTANT INSTALLATION POINTS

1.1

Ensure that the wall or supporting structure is of adequate strength to support the

heater. (Refer to table 1.)

1.2

The Water Regulations require a minimum of 350 mm unobstructed space above

the heater lid to allow the float valve to be replaced. However, a space of 200 mm is

sufficient to replace the HSR Series float valve.

1.3

The base of the heater MUST be level with, or higher than, the highest draw off

point. (Refer to figure1)

1.4

To meet the requirements of the Water Supply (Water Fittings) Regulations 1999,

Water Byelaws 2000 Scotland and the Water Regulations Northern Ireland:

1. A servicing valve shall be installed on the inlet pipe adjacent to the storage

cistern. Schedule 2 - Section 16(2).

2 . A servicing valve shall be installed on the outlet pipe.

Schedule 2 - Section 16(3).

2.0 INSTALLATION - GENERAL REQUIREMENTS

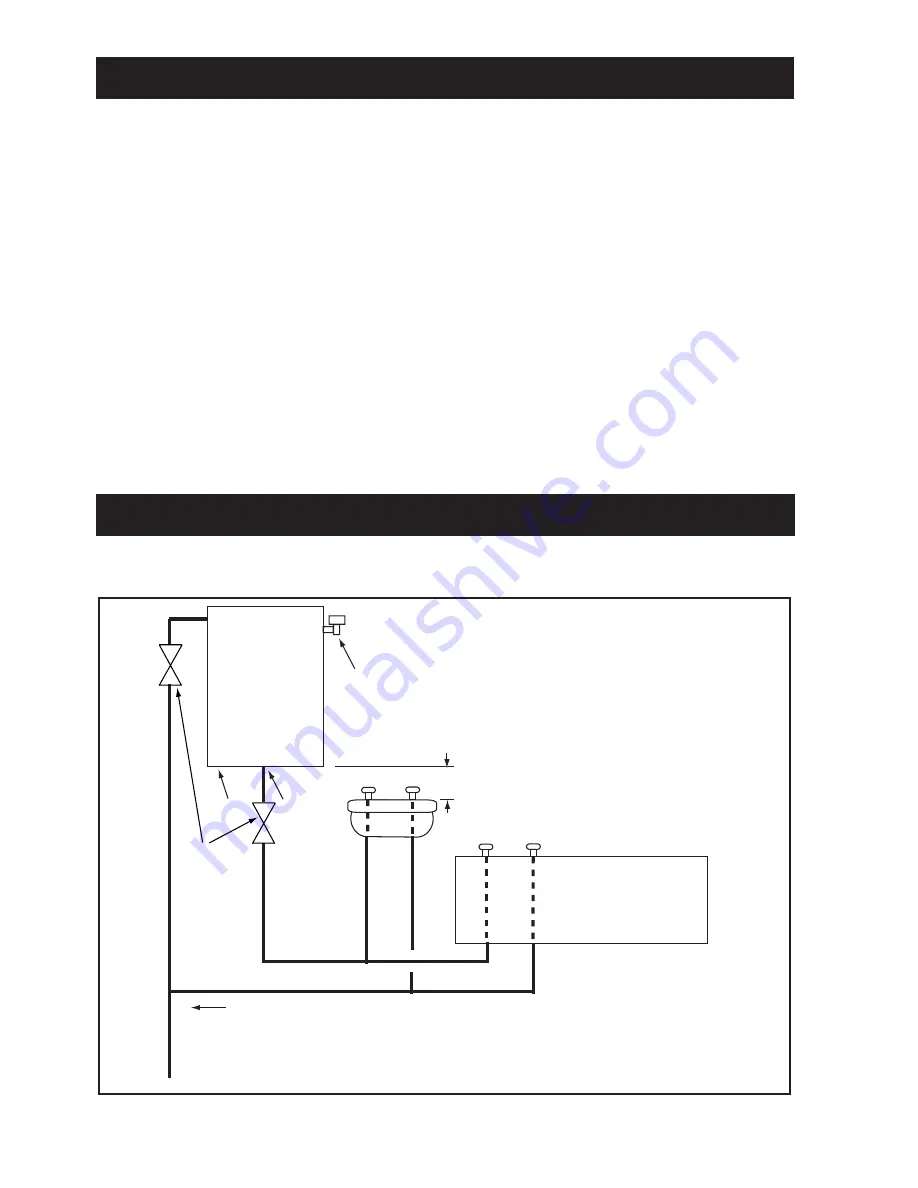

DRAIN

HOT

OUTLET

OVERFLOW

MAINS COLD FEED

NB THE HEATER MUST BE LEVEL WITH OR

HIGHER THAN THE HIGHEST OUTLET

FIG : 1 TYPICAL INSTALLATION

SERVICING

VALVES