4

2.1

Decide on the best position for the heater taking account of paragraphs 1.2 and 1.3

and inlet and outlet connections. The float valve and overflow assembly can be fitted

on either side of the heater.

2.2

Using the template provided mark the position of the top two fixing holes. Before

drilling the wall ensure there are no hidden services such as water, gas or electrical

cables embedded in the area of the wall to be drilled.

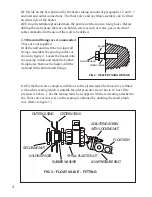

2.3 10mm wall fixings are recommended

These are not supplied

Drill the wall and insert the two top wall

fixings. Assemble the spacing collars as

shown in figure 2. Locate the heater onto

the spacing collars and mark the bottom

fixing holes. Remove the heater, drill the

wall and fit the bottom wall fixings.

2.4

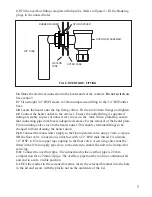

Fit the float valve complete with float, to the cistern tank.The float valve is fitted

with a white seating which is suitable for inlet pressures from 1bar to 10 bar. If the

pressure is below 1 bar the seating must be swapped with the red seating attached to

the float valve arm. Access to the seating is obtained by undoing the small plastic

nut. (Refer to figure 3.)

RUBBER WASHER

ADJUSTING SCREW

WITH LOCKING NUT

CISTERN TANK

OUTER CASING

NYLON SPACER

LOW PRESSURE SEAT

FLOAT ARM

SMALL PLASTIC NUT

FIG 3 : FLOAT VALVE - FITTING

SECURING NUT

WALL

WALL FIXING BOLT

WASHER

SPACING COLLAR

FIG 2 : HEATER FIXING DETAILS