11

Water comes in through the inlet, via a flow switch.

The flow switch measures how much water is passing through the unit.

If it detects more than the preset level of:-

2.7 litres/minute for the 9.5kW model and 3.3 litres/minute for the 10.8kW and 12.0kW models

The units heating elements are switched on. This is shown by the neon light glowing.

The water is heated instantly as it passes through the copper heat exchanger tube.

The temperature of the water coming out of the unit depends on:-

The temperature of the mains water supply

The water flow rate

The power consumption of the unit

The temperature of the main supply can vary from 5°C in winter up to about 20°C in summer, with

an average of about 12°C. The charts below show the water temperature (°C) you can expect from

the unit, operating at 9.5/10.8/12.0Kw for the different flow rates (in litres/minute)

9.5kW Multiflow

Flow rate (l/m)

3.0

4.0

6.0

Summer temp °C

_

54°

43°

Winter temp °C

50°

39°

28°

10.8kW Multiflow

Flow rate (l/m)

4.0

5.0

6.0

Summer temp °C

_

51°

46°

Winter temp °C

44°

36°

31°

12.0kW Multiflow

Flow rate (l/m)

5.0

6.0

7.0

Summer temp °C

54°

49°

44°

Winter temp °C

39°

34°

30°

This means that with the 12.0kW unit you can shower at 39°C with a flow rate of 5 litres/minute in

the middle of winter.

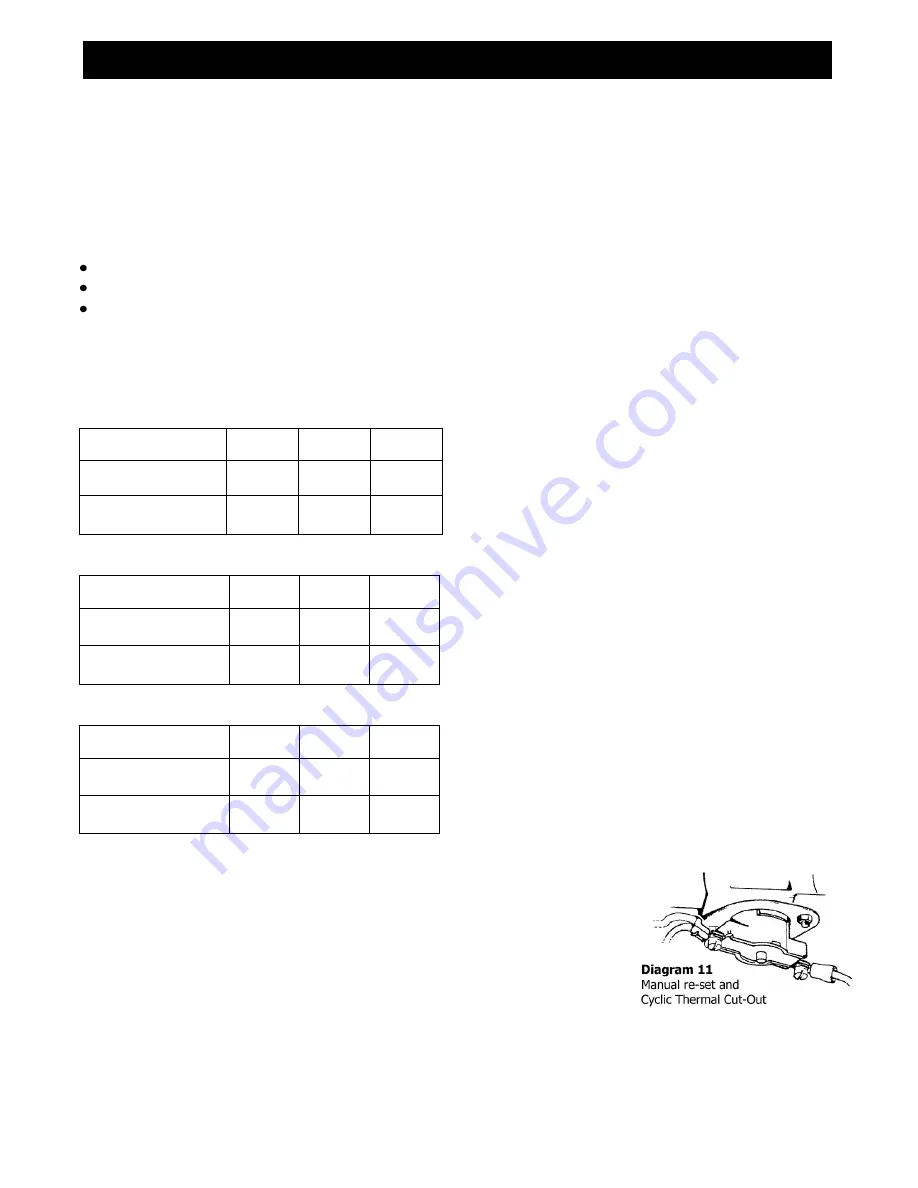

The unit includes a dual thermal cut-out (diagram 11) which is attached to

the heat exchanger tube. It will switch off the heater elements if the water

flow is reduced too much and the temperature goes above a set limit.

The first stage cut-out is cyclic and will automatically reset as the water

temperature falls. The unit will then function normally again.

The second stage cut-out when triggered needs to be reset manually inside the unit.

This cut-out will only operate in exceptional circumstances (diagram 11)

The unit can supply two outlets – for example, a shower and a basin, or up to two basins – but

water from the unit will be shared between the outlets. This is particularly important if a unit

supplies a shower and a basin, as the basin should not be used while someone is using the shower.

The unit is NOT to be fitted to a bath or kitchen sink other than for hand-washing purposes.

HOW YOUR

MULTIFLOW

WORKS

On average

(12°C main water supply at 4 litres/minute)

an outlet temperature of 46°C will be achieved.

On average

(12°C main water supply at 5 litres/minute) an

outlet temperature of 43°C will be achieved.

On average

(12°C main water supply at 6 litres/minute) an

outlet temperature of 41°C will be achieved.