230754-EN rev.2 2017-07-13

GP 24

ENGLISH

6. INSTALLATION

• First of all, check if the machine has been damaged

during the transport. If so, report this immediately to

the transport-company.

• Remove the packaging and check again that the

machine has not been damaged during the transport.

If so, report this immediately to the transport

company.

• The machine must be lifted from the right side, where

the service lid is placed.

PLEASE NOTE: The forklift must reach all the way under

the machine (see picture 1) and under the crossbeam

(see picture 2).

• Make sure there is adequate space for the machine to

operate (see picture 14).The machine requires 2 x 3,5

meters when used with two trolleys. For every extra

trolley the machine requires two meters extra (see

picture 14).

• The floor space must be even and horizontal in all

directions where the machine will operate.

• Connect compressed air of max 12 bar (174 psi) and

min 8 bar (120 psi). The connector is placed on the

right side of the unit (see picture 4). Make sure that

the air feed line to the machine is large enough to

avoid pressure drop.

• Open the door and remove the shot medium basket

(see picture 17). Put the basket aside for use later

when changing the water (see chapter 12). Empty the

enclosed bag with shot medium completely into the

machine.

• To the below left in the wash room there is a red

water level indicator (see picture 12) with two

notches. Fill the machine with water, so that the shot

medium level is within the lower notch (see picture

13) of the indicator.

PLEASE NOTE: Correct water level is extremely

important (see chapter 12).

• The machine is equipped with phase recognition

which will prevent the pump motor and rotation

motor from running in the wrong direction. If phases

are connected incorrectly, the machine will be

disabled until phases are switched. This is shown in

the LCD with title PHASE ERROR.

• If one or two of three phases are missing, the machine

will recognize this and the title PHASE MISSING will

be shown.

• In case any of these problems occur, they must be

corrected by a professional electrician.

• If there is a risk of temperature below 0ºC, the

machine must be emptied of water. Otherwise the

pump as well as the bottom tray will be damaged if

the water freezes.

7. INSTRUCTIONS FOR USE

1. Turn on the red/yellow main switch (see picture 3).

2. Place the wheels in the trolley (see picture 15).

Check that the wheels stand straight and lean on the

supports on the left with the outside of the rim facing

right, to avoid damaging the rim.

PLEASE NOTE: Decoration covers i.e. plastic centre

cap and valve caps must be removed before washing

the wheel (see picture 7).

This may cause operational

disturbances if falling off during the wash cycle (see

chapter 19).

Wheels with surfaces protruding

more than 13 mm

(1/2”)

beyond the tyre, are under no circumstances to

be washed in the Wheel Washer

(see picture 8)

. The

protruding surfaces can be damaged.

3. Move the trolley to the machine. Place the trolley so

that the second wheel support is placed to the right of

the lid

(see picture 22)

.

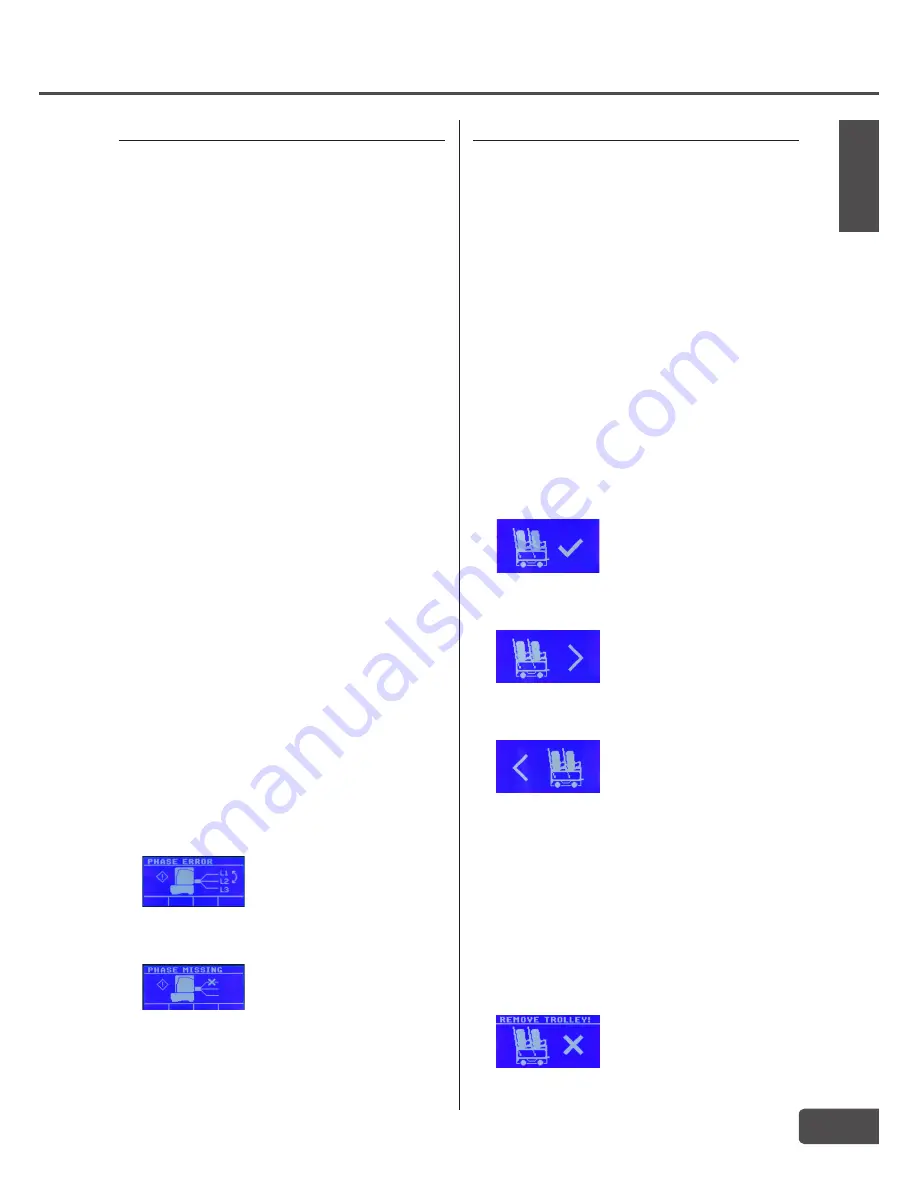

4. When the trolley stands in position and is pressed

towards the machine, the display will show the picture

below and the machine will automatically lower the

guide rail and lock the trolley to the machine then the

trolley is moved one stop to the left.

If the trolley is placed too far to the left, picture below

will be shown on the display and the trolley must be

moved to the right.

If the trolley is placed too far to the right, picture

below will be shown on the display and the trolley

must be moved to the left.

5. Start the machine (see chapter 11.3) by pressing one

of the operation buttons.

6. When the machine is washing a wheel from a

trolley, another trolley can be connected to the

first one (maximum of 4 trolleys can be connected

all together). This allows the machine to continue

washing without interruption. Please note that when

the trolley is moving no trolley may be connected.

7. When the last wheel on the trolley is washed and fed

out from the machine, the guide rail is lifted and the

trolley is disconnected from the machine. The display

will show the picture below and the trolley needs to

be removed from the machine.

Finally, always check that there are no shot medium left

on the rim before it is mounted onto the car.

5