8 Programming: Cycles

182

8.3 Cy

cle f

or Milling P

o

c

k

ets,

St

uds and Slots

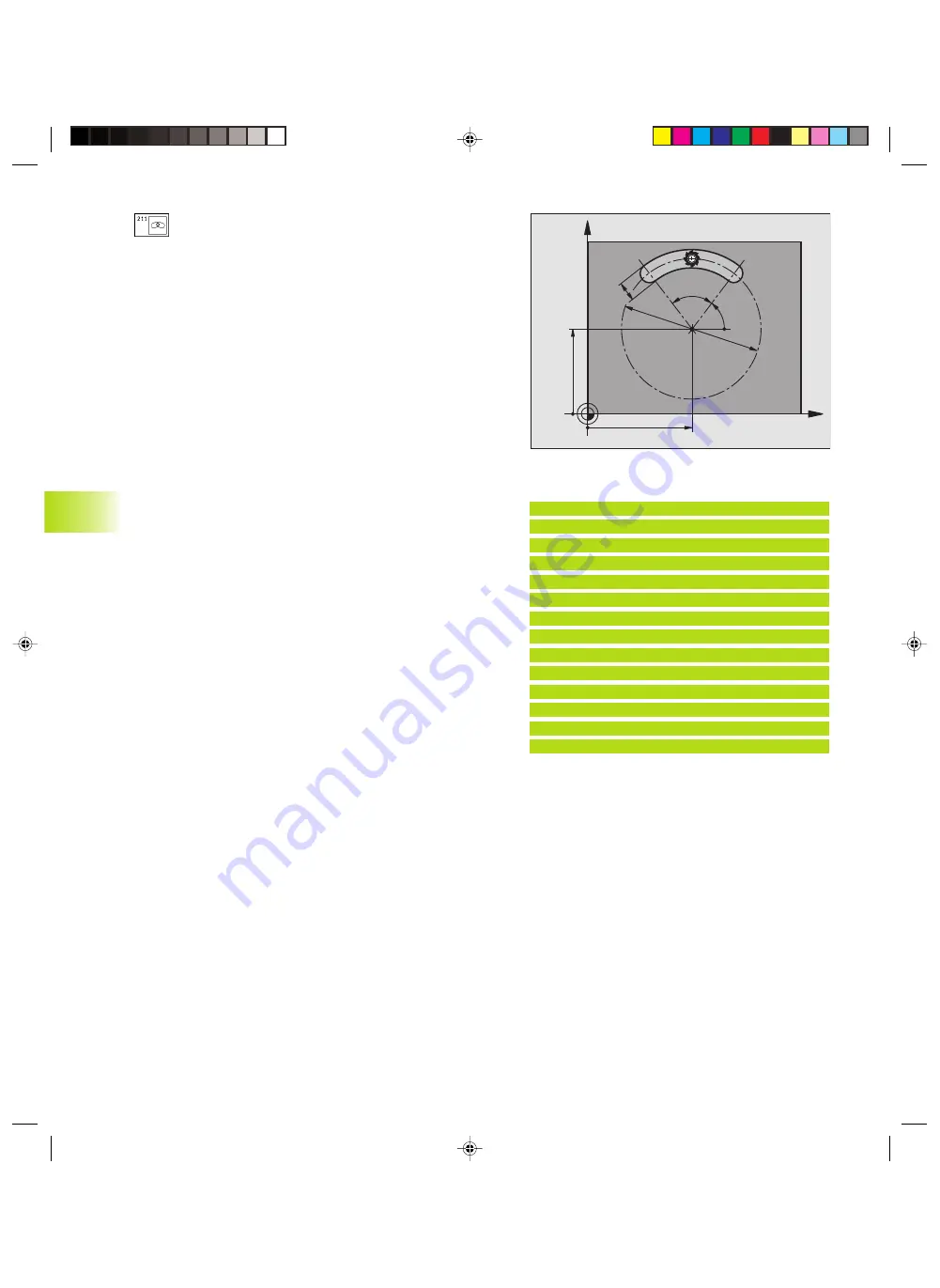

X

Y

Q217

Q216

Q248

Q245

Q219

Q244

ú

Set-up clearance Q200 (incremental value): Distance

between tool tip and workpiece surface.

ú

Depth Q201 (incremental value): Distance between

workpiece surface and bottom of slot

ú

Feed rate for milling Q207: Traversing speed of the

tool in mm/min while milling.

ú

Plunging depth Q202 (incremental value): Total extent

by which the tool is fed in the tool axis during a

reciprocating movement.

ú

Machining operation (0/1/2) Q215:

Define the extent of machining:

0

: Roughing and finishing

1

: Roughing only

2

: Finishing only

ú

Workpiece SURFACE COORDINATE Q203 (absolute

value): Coordinate of the workpiece surface

ú

2nd set-up clearance Q204 (incremental value): Z

coordinate at which no collision between tool and

workpiece (clamping devices) can occur.

ú

Center in 1st axis Q216 (absolute value): Center of the

slot in the main axis of the working plane

ú

Center in 2nd axis Q217 (absolute value): Center of the

slot in the secondary axis of the working plane

ú

Pitch circle diameter Q244: Enter the diameter of the

pitch circle

ú

Second side length Q219: Enter the slot width. If you

enter a slot width that equals the tool diameter, the

TNC will carry out the roughing process only (slot

milling).

ú

Starting angle Q245 (absolute value): Enter the polar

angle of the starting point.

ú

Angular length Q248 (incremental value): Enter the

angular length of the slot

Example NC blocks:

52 CYCL DEF 211 CIRCULAR SLOT

Q200=2

;SET-UP CLEARANCE

Q201=-20

;DEPTH

Q207=500

;FEED RATE FOR MILLING

Q202=5

;PLUNGING DEPTH

Q215=0

;MACHINING OPERATION

Q203=+0

;SURFACE COORDINATE

Q204=50

;2. SET-UP CLEARANCE

Q216=+50

;CENTER IN 1ST AXIS

Q217=+50

;CENTER IN 2ND AXIS

Q244=80

;PITCH CIRCLE DIAMETER

Q219=12

;2ND SIDE LENGTH

Q245=+45

;STARTING ANGLE

Q248=90

;ANGULAR LENGTH

kkap8.pm6

30.06.2006, 07:03

182

www.EngineeringBooksPdf.com

Summary of Contents for TNC 426 B

Page 3: ...BAUSKLA PM6 30 06 2006 07 03 2 www EngineeringBooksPdf com ...

Page 4: ...BAUSKLA PM6 30 06 2006 07 03 3 www EngineeringBooksPdf com ...

Page 6: ...CINHALT PM6 30 06 2006 07 03 2 www EngineeringBooksPdf com ...

Page 16: ...CINHALT PM6 30 06 2006 07 03 12 www EngineeringBooksPdf com ...

Page 17: ...Introduction 1 Dkap1 pm6 30 06 2006 07 03 1 www EngineeringBooksPdf com ...

Page 29: ...Manual Operation and Setup 2 Dkap2_3 pm6 30 06 2006 07 03 13 www EngineeringBooksPdf com ...

Page 83: ...Programming Tools 5 Fkap5 pm6 30 06 2006 07 03 67 www EngineeringBooksPdf com ...

Page 106: ...Fkap5 pm6 30 06 2006 07 03 90 www EngineeringBooksPdf com ...

Page 107: ...Programming Programming Contours 6 Gkap6 pm6 30 06 2006 07 04 91 www EngineeringBooksPdf com ...

Page 165: ...Hkap7 pm6 30 06 2006 07 03 150 www EngineeringBooksPdf com ...

Page 166: ...Programming Cycles 8 kkap8 pm6 30 06 2006 07 03 151 www EngineeringBooksPdf com ...

Page 253: ...kkap8 pm6 30 06 2006 07 04 238 www EngineeringBooksPdf com ...

Page 265: ...LKAP9 PM6 30 06 2006 07 04 250 www EngineeringBooksPdf com ...

Page 266: ...Programming Q Parameters 10 MKAP10 PM6 30 06 2006 07 04 251 www EngineeringBooksPdf com ...

Page 297: ...MKAP10 PM6 30 06 2006 07 04 282 www EngineeringBooksPdf com ...

Page 298: ...Test Run and Program Run 11 NKAP11 PM6 30 06 2006 07 04 283 www EngineeringBooksPdf com ...

Page 312: ...MOD Functions 12 Okap12 pm6 30 06 2006 07 04 297 www EngineeringBooksPdf com ...

Page 332: ...Tables and Overviews 13 Pkap13 pm6 30 06 2006 07 04 317 www EngineeringBooksPdf com ...