Path contours – Polar coordinates

6.5

6

HEIDENHAIN | TNC 620 | ISO Programming User's Manual | 9/2016

265

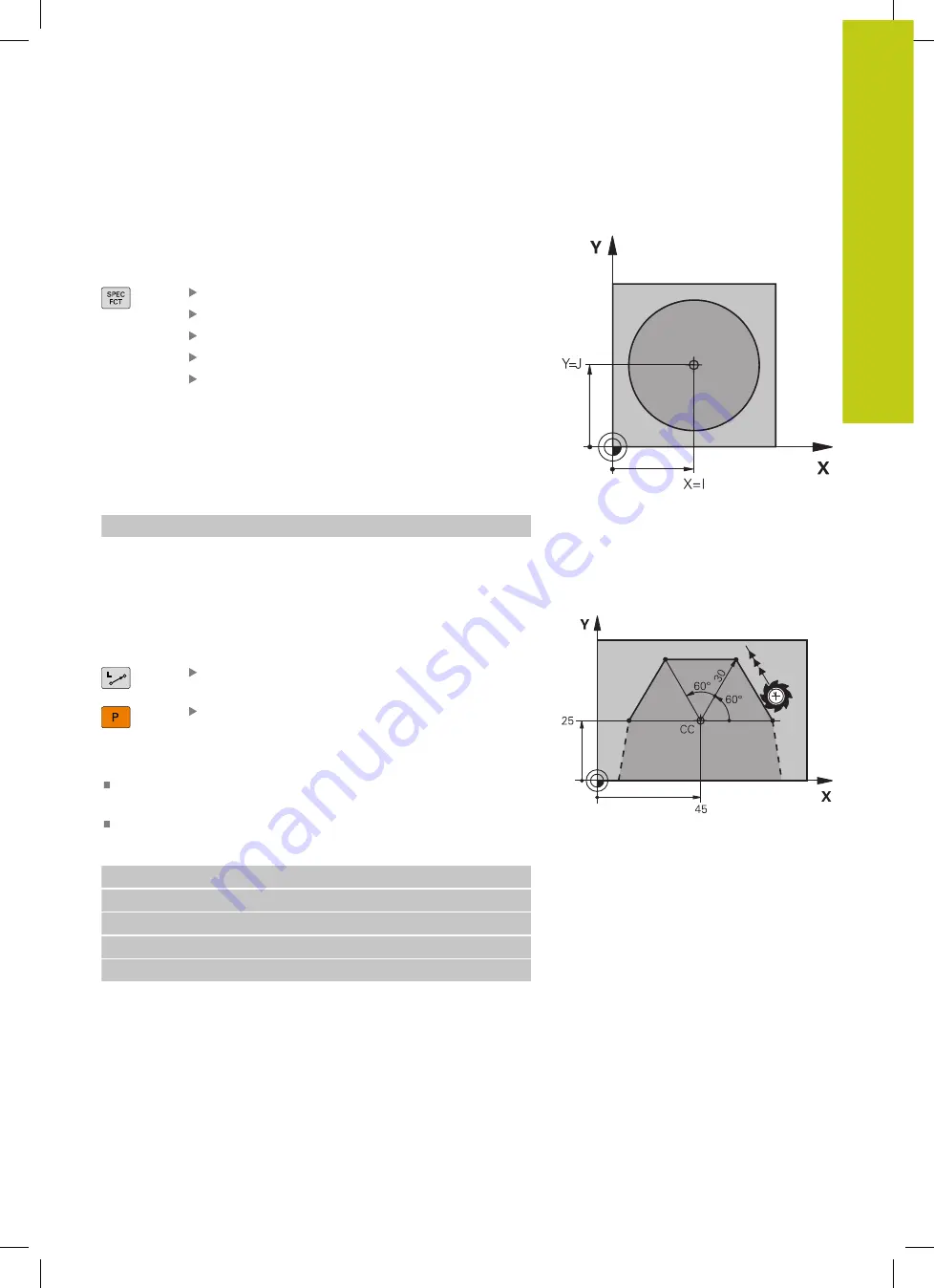

Zero point for polar coordinates: pole I, J

You can set the pole (I, J) at any point in the machining program,

before indicating points in polar coordinates. Set the pole in the

same way as you would program the circle center.

To program a pole, press the

SPEC FCT

key.

Press the

PROGRAM FUNCTIONS

soft key

Press the

DIN/ISO

soft key

Press the

I

or

J

soft key

Coordinates

: Enter Cartesian coordinates for the

pole or, if you want to use the last programmed

position, enter

G29

. Before programming polar

coordinates, define the pole. You can only define

the pole in Cartesian coordinates. The pole

remains in effect until you define a new pole.

Example NC blocks

N120 I+45 J+45*

Straight line in rapid traverse G10 or straight line

with feed rate F G11

The tool moves in a straight line from its current position to the

straight-line end point. The starting point is the end point of the

preceding block.

Polar coordinate radius R

: Enter the distance

from the pole CC to the straight-line end point.

Polar coordinate angle H

: Angular position of the

straight-line end point between –360° and +360°

The sign of

H

depends on the angle reference axis:

If the angle from the angle reference axis to

R

is

counterclockwise:

H

>0

If the angle from the angle reference axis to

R

is clockwise:

H

<0

Example NC blocks

N120 I+45 J+45*

N130 G11 G42 R+30 H+0 F300 M3*

N140 H+60*

N150 G91 H+60*

N160 G90 H+180*

Summary of Contents for TNC 620 Programming Station

Page 4: ......

Page 5: ...Fundamentals ...

Page 28: ...Contents 28 HEIDENHAIN TNC 620 ISO Programming User s Manual 9 2016 ...

Page 57: ...1 First Steps with the TNC 620 ...

Page 77: ...2 Introduction ...

Page 110: ......

Page 111: ...3 Fundamentals file management ...

Page 166: ......

Page 167: ...4 Programming aids ...

Page 194: ......

Page 195: ...5 Tools ...

Page 234: ......

Page 235: ...6 Programming contours ...

Page 284: ......

Page 285: ...7 Data transfer from CAD files ...

Page 304: ......

Page 305: ...8 Subprograms and program section repeats ...

Page 323: ...9 Programming Q parameters ...

Page 384: ......

Page 385: ...10 Miscellaneous functions ...

Page 407: ...11 Special functions ...

Page 433: ...12 Multiple axis machining ...

Page 475: ...13 Pallet management ...

Page 480: ......

Page 481: ...14 Manual Operation and Setup ...

Page 549: ...15 Positioning with Manual Data Input ...

Page 554: ......

Page 555: ...16 Test Run and Program Run ...

Page 590: ......

Page 591: ...17 MOD Functions ...

Page 622: ......

Page 623: ...18 Tables and Overviews ...