DXF converter (option 42)

7.3

7

HEIDENHAIN | TNC 620 | ISO Programming User's Manual | 9/2016

291

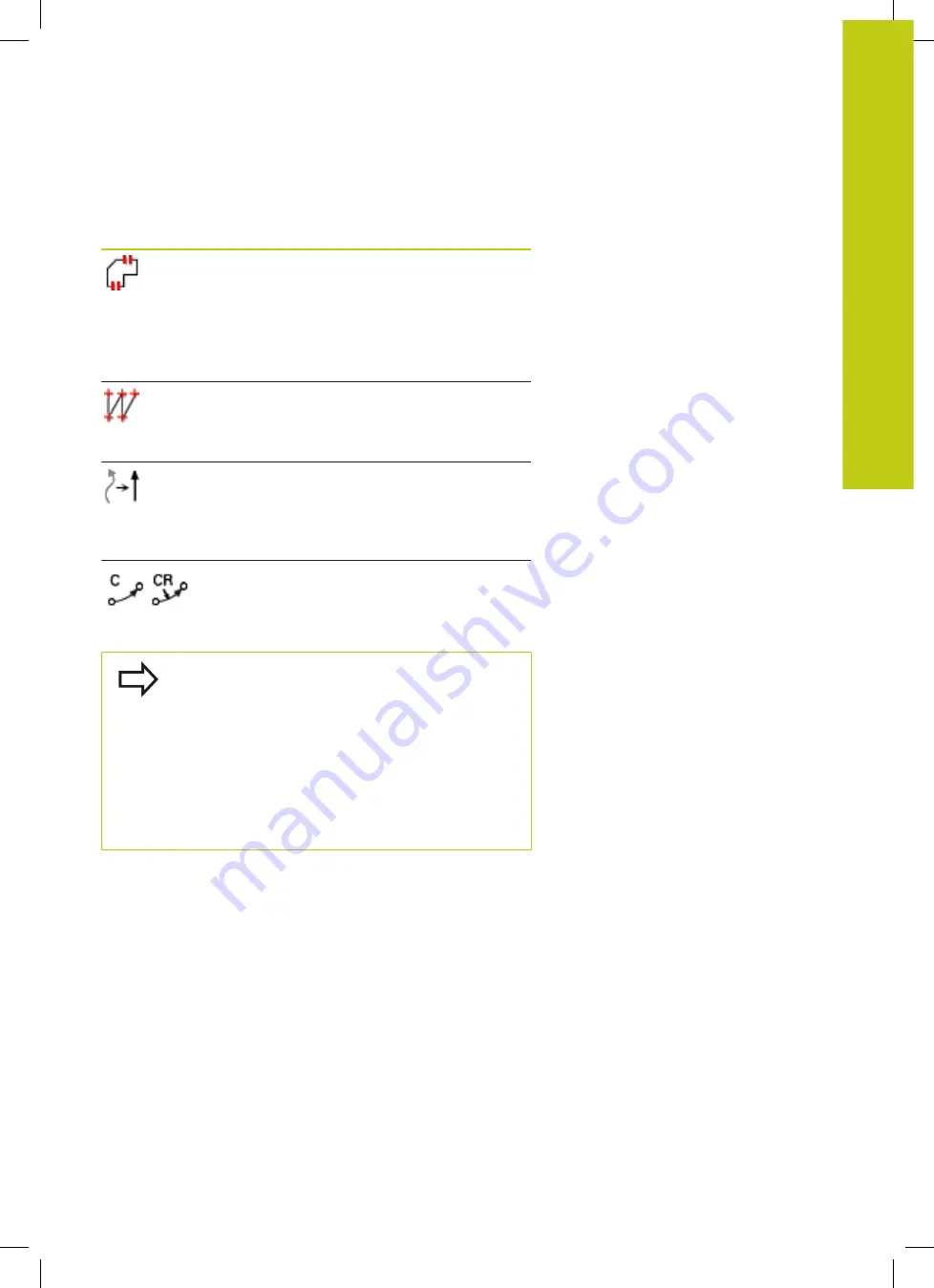

The following icons are displayed by the TNC only in certain modes.

Icon

Setting

Contour assumption mode:

The tolerance specifies how far apart

neighboring contour elements may be from

each other. You can use the tolerance to

compensate for inaccuracies that occurred

when the drawing was made. The default

setting is 0.001 mm

Point assumption mode:

Specify whether the TNC should display the

tool path as a dashed straight line during

selection of machining positions

Path optimization mode:

The TNC optimizes the tool traverse movement

to give the shortest traverse movements

between the machining positions. Optimization

is reset with repeated actuations

Arc mode:

Arc mode determines whether circles should

be produced in C format or CR format, e.g. for

cylinder coat interpolations in the NC program.

Please note that you must set the correct unit of

measurement, since the DXF file does not contain

any such information.

If you want to generate programs for older TNC

controls, you must limit the resolution to three

decimal places. In addition, you must remove the

comments that the DXF converter inserts into the

contour program.

The TNC displays the active basic settings in the

footer of the screen.

Summary of Contents for TNC 620 Programming Station

Page 4: ......

Page 5: ...Fundamentals ...

Page 28: ...Contents 28 HEIDENHAIN TNC 620 ISO Programming User s Manual 9 2016 ...

Page 57: ...1 First Steps with the TNC 620 ...

Page 77: ...2 Introduction ...

Page 110: ......

Page 111: ...3 Fundamentals file management ...

Page 166: ......

Page 167: ...4 Programming aids ...

Page 194: ......

Page 195: ...5 Tools ...

Page 234: ......

Page 235: ...6 Programming contours ...

Page 284: ......

Page 285: ...7 Data transfer from CAD files ...

Page 304: ......

Page 305: ...8 Subprograms and program section repeats ...

Page 323: ...9 Programming Q parameters ...

Page 384: ......

Page 385: ...10 Miscellaneous functions ...

Page 407: ...11 Special functions ...

Page 433: ...12 Multiple axis machining ...

Page 475: ...13 Pallet management ...

Page 480: ......

Page 481: ...14 Manual Operation and Setup ...

Page 549: ...15 Positioning with Manual Data Input ...

Page 554: ......

Page 555: ...16 Test Run and Program Run ...

Page 590: ......

Page 591: ...17 MOD Functions ...

Page 622: ......

Page 623: ...18 Tables and Overviews ...