Positioning with Manual Data Input

15.1 Programming and executing simple machining operations

15

552

HEIDENHAIN | TNC 620 | ISO Programming User's Manual | 9/2016

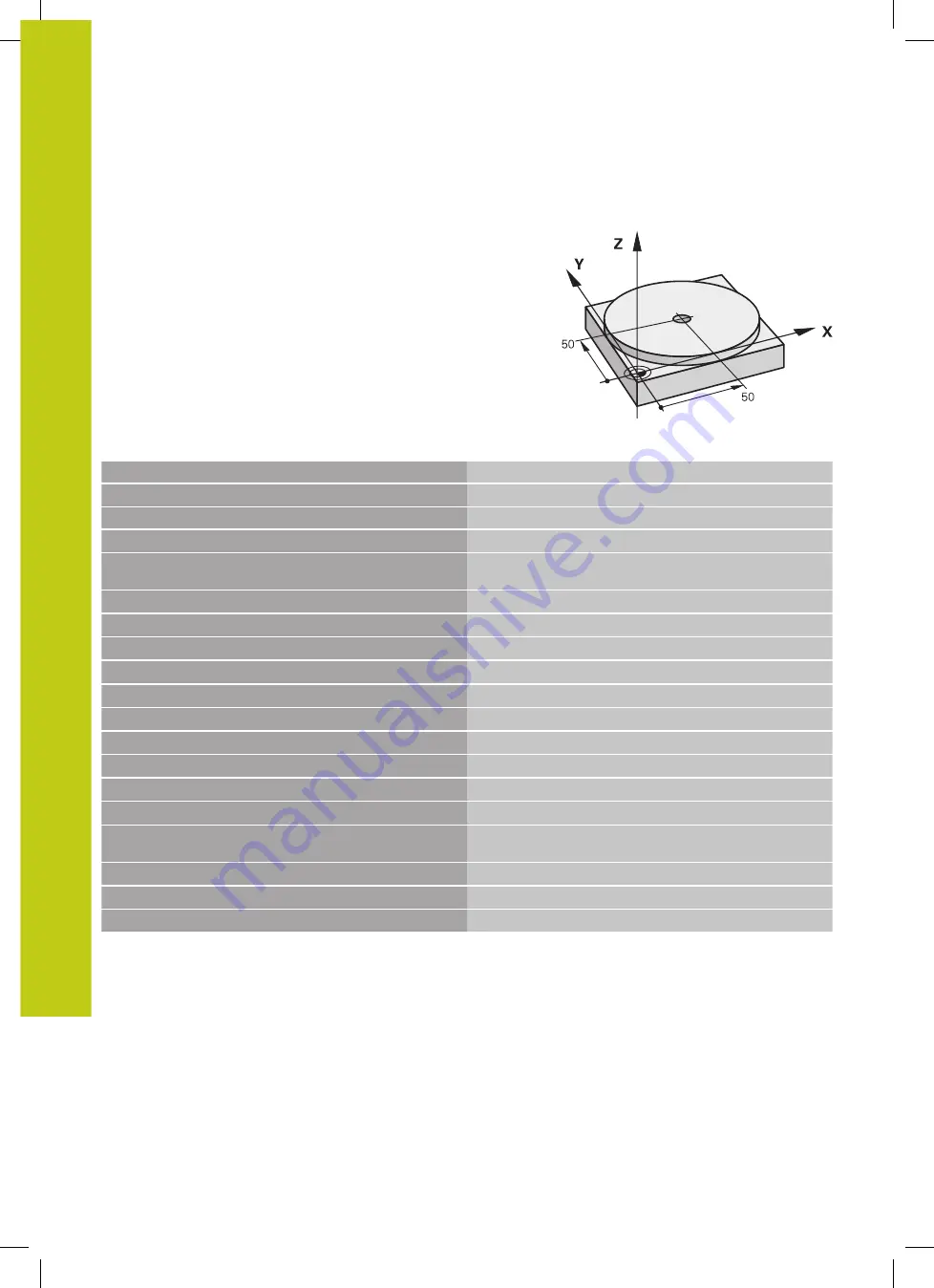

Example 1

A hole with a depth of 20 mm is to be drilled into a single

workpiece. After clamping and aligning the workpiece and setting

the datum, you can program and execute the drilling operation with

a few lines of programming.

First you pre-position the tool above the workpiece with straight-

line blocks and position with a safety clearance of 5 mm above the

hole. Then drill the hole with Cycle

G200

.

%$MDI G71 *

N10 T1 G17 S2000*

Call the tool: tool axis Z,

spindle speed 2000 rpm

N20 G00 G40 G90 Z+200*

Retract the tool (rapid traverse)

N30 X+50 Y+50 M3*

Move the tool at rapid traverse to a position above the hole.

Spindle on.

N40 G01 Z+2 F2000*

Position the tool to 2 mm above the hole

N50 G200 DRILLING

Define Cycle G200 DRILLING

Q200=2

;SET-UP CLEARANCE

Set-up clearance of the tool above the hole

Q201=-20

;DEPTH

Hole depth (algebraic sign=working direction)

Q206=250

;FEED RATE FOR PLNGNG

Feed rate for drilling

Q202=10

;PLUNGING DEPTH

Depth of each infeed before retraction

Q210=0

;DWELL TIME AT TOP

Dwell time at top for chip release (in seconds)

Q203=+0

;SURFACE COORDINATE

Workpiece surface coordinate

Q204=50

;2ND SET-UP CLEARANCE

Position after the cycle, with respect to Q203

Q211=0.5

;DWELL TIME AT DEPTH

Dwell time in seconds at the hole bottom

Q395=0

;DEPTH REFERENCE

Depth referenced to the tool tip or the cylindrical part of the

tool

N60 G79*

Call Cycle G200 PECKING

N70 G00 G40 Z+200 M2*

Retract the tool

N9999999 %$MDI G71 *

End of program

Straight-line function:

Summary of Contents for TNC 620 Programming Station

Page 4: ......

Page 5: ...Fundamentals ...

Page 28: ...Contents 28 HEIDENHAIN TNC 620 ISO Programming User s Manual 9 2016 ...

Page 57: ...1 First Steps with the TNC 620 ...

Page 77: ...2 Introduction ...

Page 110: ......

Page 111: ...3 Fundamentals file management ...

Page 166: ......

Page 167: ...4 Programming aids ...

Page 194: ......

Page 195: ...5 Tools ...

Page 234: ......

Page 235: ...6 Programming contours ...

Page 284: ......

Page 285: ...7 Data transfer from CAD files ...

Page 304: ......

Page 305: ...8 Subprograms and program section repeats ...

Page 323: ...9 Programming Q parameters ...

Page 384: ......

Page 385: ...10 Miscellaneous functions ...

Page 407: ...11 Special functions ...

Page 433: ...12 Multiple axis machining ...

Page 475: ...13 Pallet management ...

Page 480: ......

Page 481: ...14 Manual Operation and Setup ...

Page 549: ...15 Positioning with Manual Data Input ...

Page 554: ......

Page 555: ...16 Test Run and Program Run ...

Page 590: ......

Page 591: ...17 MOD Functions ...

Page 622: ......

Page 623: ...18 Tables and Overviews ...