Programming Q parameters

9.12 Programming examples

9

378

HEIDENHAIN | TNC 620 | ISO Programming User's Manual | 9/2016

9.12

Programming examples

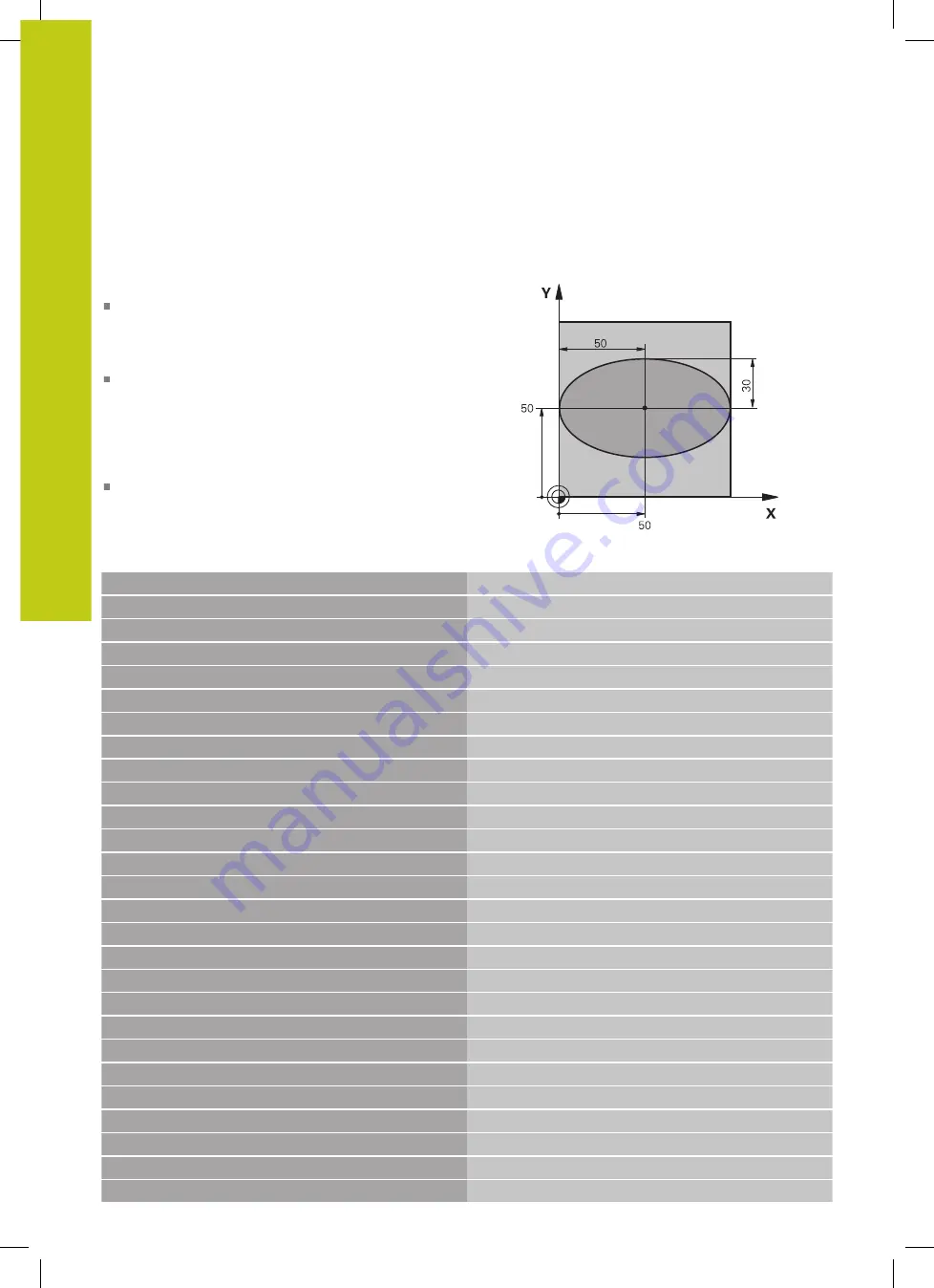

Example: Ellipse

Program run

The contour of the ellipse is approximated by many

short lines (defined in Q7). The more calculation

steps you define for the lines, the smoother the curve

becomes.

The milling direction is determined with the starting

angle and end angle in the plane:

Machining direction is clockwise:

Starting angle > end angle

Machining direction is counterclockwise:

Starting angle < end angle

The tool radius is not taken into account

%ELLIPSE G71 *

N10 D00 Q1 P01 +50*

Center in X axis

N20 D00 Q2 P01 +50*

Center in Y axis

N30 D00 Q3 P01 +50*

Semiaxis in X

N40 D00 Q4 P01 +30*

Semiaxis in Y

N50 D00 Q5 P01 +0*

Starting angle in the plane

N60 D00 Q6 P01 +360*

End angle in the plane

N70 D00 Q7 P01 +40*

Number of calculation steps

N80 D00 Q8 P01 +30*

Rotational position of the ellipse

N90 D00 Q9 P01 +5*

Milling depth

N100 D00 Q10 P01 +100*

Feed rate for plunging

N110 D00 Q11 P01 +350*

Feed rate for milling

N120 D00 Q12 P01 +2*

Set-up clearance for pre-positioning

N130 G30 G17 X+0 Y+0 Z-20*

Workpiece blank definition

N140 G31 G90 X+100 Y+100 Z+0*

N150 T1 G17 S4000*

Tool call

N160 G00 G40 G90 Z+250*

Retract the tool

N170 L10.0*

Call machining operation

N180 G00 Z+250 M2*

Retract the tool, end program

N190 G98 L10*

Subprogram 10: Machining operation

N200 G54 X+Q1 Y+Q2*

Shift datum to center of ellipse

N210 G73 G90 H+Q8*

Account for rotational position in the plane

N220 Q35 = ( Q6 - Q5 ) / Q7

Calculate angle increment

N230 D00 Q36 P01 +Q5*

Copy starting angle

N240 D00 Q37 P01 +0*

Set counter

N250 Q21 = Q3 * COS Q36

Calculate X coordinate for starting point

N260 Q22 = Q4 * SIN Q36

Calculate Y coordinate for starting point

Summary of Contents for TNC 620 Programming Station

Page 4: ......

Page 5: ...Fundamentals ...

Page 28: ...Contents 28 HEIDENHAIN TNC 620 ISO Programming User s Manual 9 2016 ...

Page 57: ...1 First Steps with the TNC 620 ...

Page 77: ...2 Introduction ...

Page 110: ......

Page 111: ...3 Fundamentals file management ...

Page 166: ......

Page 167: ...4 Programming aids ...

Page 194: ......

Page 195: ...5 Tools ...

Page 234: ......

Page 235: ...6 Programming contours ...

Page 284: ......

Page 285: ...7 Data transfer from CAD files ...

Page 304: ......

Page 305: ...8 Subprograms and program section repeats ...

Page 323: ...9 Programming Q parameters ...

Page 384: ......

Page 385: ...10 Miscellaneous functions ...

Page 407: ...11 Special functions ...

Page 433: ...12 Multiple axis machining ...

Page 475: ...13 Pallet management ...

Page 480: ......

Page 481: ...14 Manual Operation and Setup ...

Page 549: ...15 Positioning with Manual Data Input ...

Page 554: ......

Page 555: ...16 Test Run and Program Run ...

Page 590: ......

Page 591: ...17 MOD Functions ...

Page 622: ......

Page 623: ...18 Tables and Overviews ...