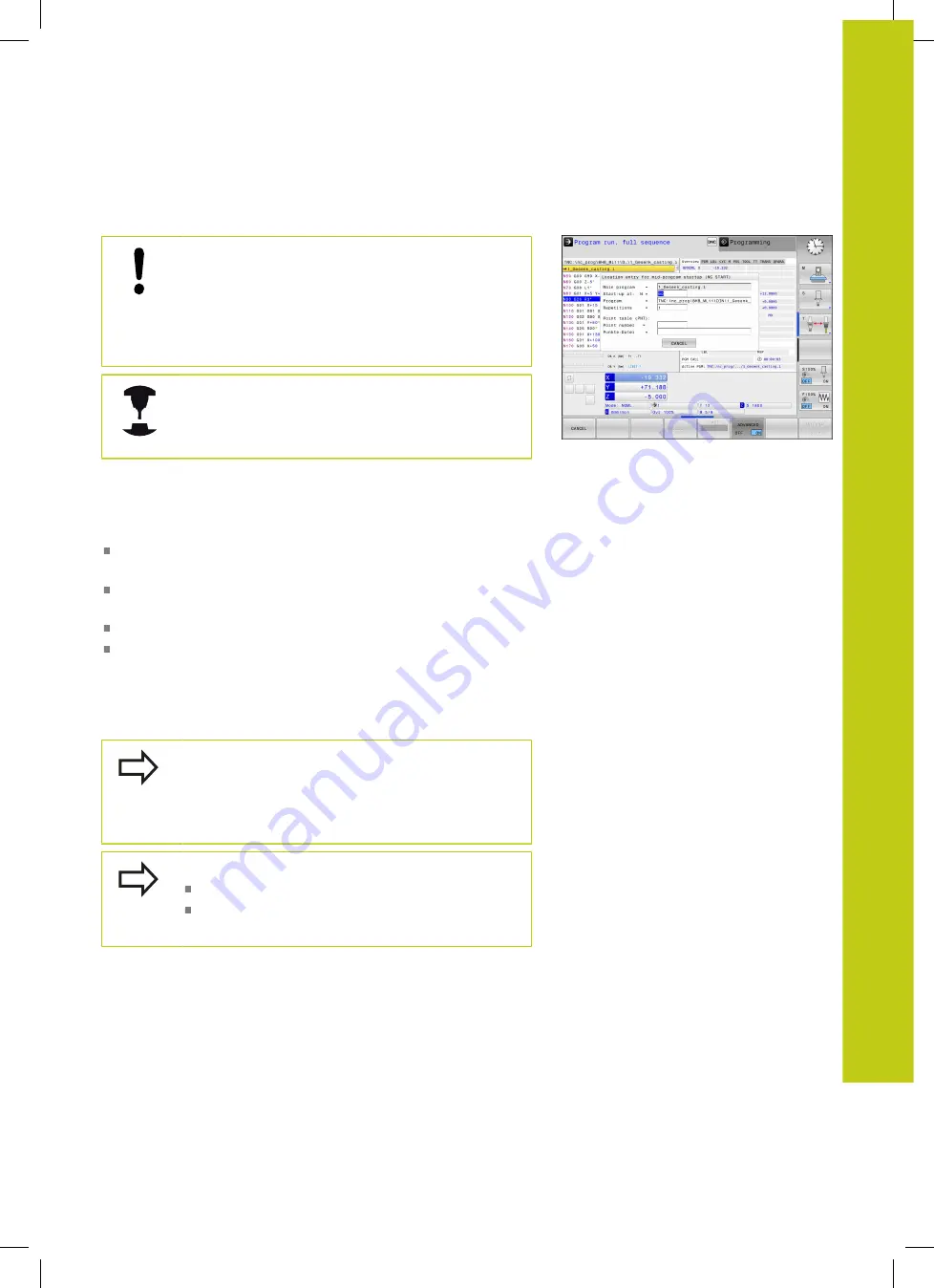

Program run 16.5

16

HEIDENHAIN | TNC 620 | ISO Programming User's Manual | 9/2016

581

Any entry into program: Mid-program startup

Danger of collision!

If you use the

GOTO

key and the number of the NC

block for going into a program, neither the TNC nor

the PLC will execute any functions that ensure a safe

start.

For safe entry, always use the

BLOCK SCAN

function.

The

BLOCK SCAN

function must be enabled and

adapted by the machine manufacturer. Refer to your

machine manual.

With the

BLOCK SCAN

function you can start an NC program at any

desired NC block. The control factors workpiece machining up to

this NC block into the calculations.

You can run the mid-program startup in the following ways:

Mid-program startup in the main program, with repetitions if

necessary

Multi-level mid-program startup in subprograms and touch probe

cycles

Mid-program startup in a point table

Block scan in pallet programs

At the start of mid-program startup the control resets all data,

as with a selection of the NC program. During the mid-program

startup you can change between

Program run full sequence

and

Program run single block

.

The TNC skips all touch probe cycles in a

midprogramstartup. Result parameters from these

cycles might therefore remain empty. If you wish to

continue working with the results of a touch probe

cycle, use the multi-level mid-program startup.

You must not use mid-program startup if you:

The stretch filter is activated

use the touch probe cycle G55 in the search

phase of the mid-program startup

Summary of Contents for TNC 620 Programming Station

Page 4: ......

Page 5: ...Fundamentals ...

Page 28: ...Contents 28 HEIDENHAIN TNC 620 ISO Programming User s Manual 9 2016 ...

Page 57: ...1 First Steps with the TNC 620 ...

Page 77: ...2 Introduction ...

Page 110: ......

Page 111: ...3 Fundamentals file management ...

Page 166: ......

Page 167: ...4 Programming aids ...

Page 194: ......

Page 195: ...5 Tools ...

Page 234: ......

Page 235: ...6 Programming contours ...

Page 284: ......

Page 285: ...7 Data transfer from CAD files ...

Page 304: ......

Page 305: ...8 Subprograms and program section repeats ...

Page 323: ...9 Programming Q parameters ...

Page 384: ......

Page 385: ...10 Miscellaneous functions ...

Page 407: ...11 Special functions ...

Page 433: ...12 Multiple axis machining ...

Page 475: ...13 Pallet management ...

Page 480: ......

Page 481: ...14 Manual Operation and Setup ...

Page 549: ...15 Positioning with Manual Data Input ...

Page 554: ......

Page 555: ...16 Test Run and Program Run ...

Page 590: ......

Page 591: ...17 MOD Functions ...

Page 622: ......

Page 623: ...18 Tables and Overviews ...