INSTALLATION INSTRUCTIONS

Fan Coils: FEM4X, FEM4P, REM4X, FXM4X

8

496 01 5503 02

Specifications are subject to change without notice.

ELECTRICAL CONNECTIONS

These Fan Coils do not have a printed circuit board (PCB), they

have a low voltage circuit protective fuse (3 amp) inline on the

wire harness. Speed selections are made at the fan motor with

the Blue wire. The motor is pre

−

programmed with the

time

−

delay circuit on some of the speed taps. (See Page 9,

Section D)

Before proceeding with electrical connections, make certain

that supply voltage, frequency, phase, and circuit ampacity are

as specified on the unit rating plate. See unit wiring label for

proper field high and low voltage wiring.

!

WARNING

ELECTRICAL SHOCK or UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or unit damage.

If a disconnect switch is to be mounted on unit, select a

location where drill and fasteners will not contact electrical

or refrigeration components.

Make all electrical connections in accordance with the NEC

and any local codes or ordinances that may apply. Use

copper wire only. The unit must have a separate branch

electric circuit with a field

−

supplied disconnect switch located

within sight of and readily accessible from the unit.

NOTE:

When a pull

−

out type disconnect is removed from the

unit, only the Load side of the circuit is de

−

energized. The

Line side remains live until the main (remote) disconnect is

turned off.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Turn off the main (remote) disconnect device before

working on incoming (field) wiring.

Incoming (field) wires on the line side of the disconnect

found in the fan coil unit remain live, even when the

pull

−

out is removed. Service and maintenance to

incoming (field) wiring cannot be performed until the main

disconnect switch (remote to the unit) is turned off.

A. LINE VOLTAGE CONNECTIONS

Fan Coils installed without electric heat require the use of a

factory

−

authorized Power Plug Kit (accessory part number

EBAC01PLG). This kit provides the electrical connections

necessary to supply the unit with 208/230V power when

electric heat is not present. For units without electric heat:

1. Connect 208/230V power leads from field disconnect

to yellow and black stripped leads on Power Plug

(accessory part number EBAC01PLG).

2. Connect ground wire to unit ground lug.

3. When installing an electric heater, remove and discard

power plug (if equipped) from fan coil and connect

male plug from heater to female plug from unit wiring

harness. (See Electric Heater Installation

Instructions.)

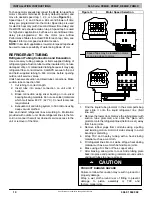

B. 24V CONTROL SYSTEM

Connection to Unit

Wire low

−

voltage in accordance with wiring label on the

blower (also refer to

). Use 18

AWG color

−

coded, insulated (35

°

C minimum) wire to make

the low

−

voltage connections between the thermostat, the

unit, and the outdoor equipment. If the thermostat is located

more than 100 feet from the unit (as measured along the low

voltage wire), use 16 AWG color

−

coded, insulated (35

°

C

minimum) wire. All wiring must be NEC Class 1 and must be

separated from incoming power leads. Refer to outdoor unit

wiring instructions for additional wiring recommendations.

Heater Staging

If electric heat staging is required, a multi

−

stage heating

room thermostat is required. Consult your equipment

supplier for a suitable thermostat.

Manufactured Housing

In manufactured housing applications, the Code of Federal

Regulations, Title 24, Chapter XX, Part 3280.714 requires

that supplemental electric heat be locked out at outdoor

temperatures above 40

_

F (4

_

C), except for a heat pump

defrost cycle. Refer to

for typical low

−

voltage

wiring with outdoor thermostat.

Figure 9

Wiring Layout

−

Air Conditioning

Unit (Cooling Only)

R

G

W

Y

THERMOSTAT

RED

GRY

WHT

BLU

VIO

BRN

WHT

R

G

W

2

W

3

E

C

FAN COIL

(CONTROL)

C

Y

AIR COND.