Issued September 2017

Compressed Natural Gas (CNG) Option

Copyright 2017, Heil Environmental

Printed in U.S.A.

174

INSPECTION/PREVENTIVE CARE SCHEDULE

Table 1. Inspection/Preventive Care Schedule

ITEM

FREQUENCY

Storage System:

Leak Test with

Methane Detector*

Every month

Component

Inspection*

Every month

Drain Filter

Every 10,000 miles

Replace Filter

Element

Every 40,000 miles

Drain Vent Lines

Every month (or immediately if

blue vent cap is missing)

Cylinders*

Inspect compressed gas cylinders

as outlined by cylinder

manufacturer

* To be completed by a qualified and trained person.

PREPARATION BEFORE MAINTENANCE

It is necessary to prepare the truck to be serviced. A

mechanic’s initial focus while preparing the vehicle for

service should be safety. The primary preparation involves

relieving the pressure within the system BEFORE

performing any maintenance procedures.

Follow the steps as outlined to ensure that no pressure

remains.

1. Leave the Fuel Management Module Manual Shut-

Off Valve in the ‘ON’ position.

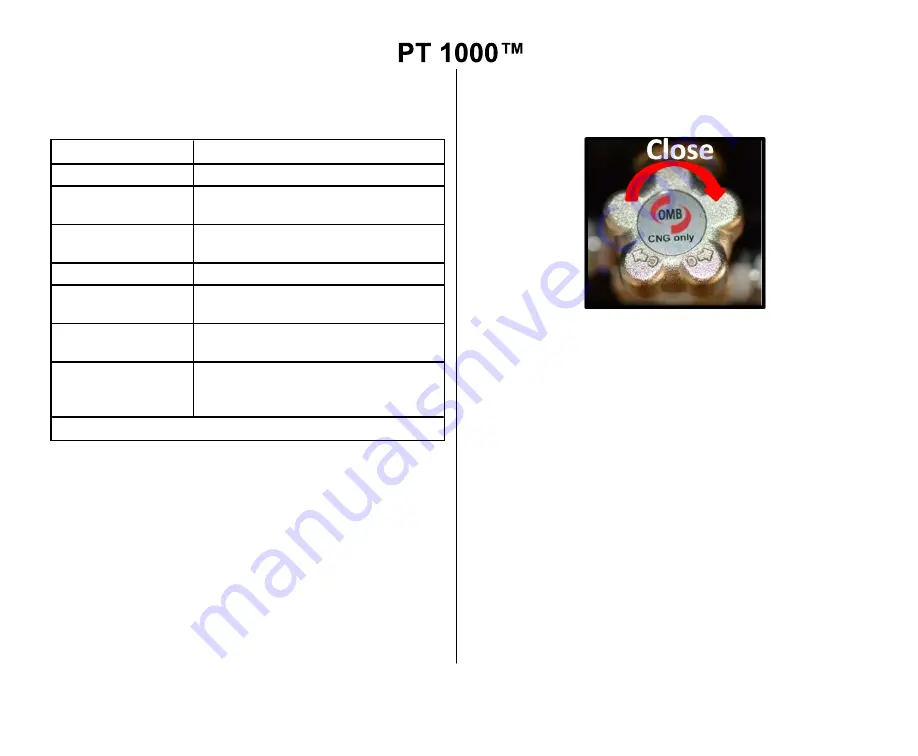

2. Turn OFF each supply tank’s valve(s) inside CNrG

Tailgate.

Figure 86. Tank Valve

3. Start the vehicle's engine, allowing it to run until the

engine shuts off. This will ensure that all CNG in the

lines has been consumed.

4. As an added safety precaution, open the system

purge valve to ensure no latent pressure remains.

5. Ensure the high pressure gauge on the fuel control

module reads 0 psi.

6. Turn off the power supply if an electrical component

of the system requires service.

7. Perform any maintenance ONLY after completing

these instructions.

See the

Compressed Natural Gas (CNG)

section of your

Service Manual for additional maintenance information.

Summary of Contents for PT 1000

Page 8: ...NOTES...

Page 10: ...NOTES 2...

Page 36: ...NOTES 28...

Page 64: ...NOTES 56...

Page 68: ...NOTES 60...

Page 84: ...NOTES 76...

Page 90: ...NOTES 82...

Page 150: ...NOTES 142...

Page 154: ...NOTES 146...

Page 158: ...NOTES 150...

Page 162: ...NOTES 154...

Page 200: ...NOTES 192...