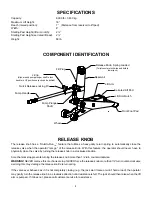

REPLACEMENT PARTS

(refer to page 12 & 13)

Not all components of the jack are replacement items, but are illustrated as a convenient reference of location and

position in the assembly sequence. When ordering parts, give model number, part number and parts description. Call

or write for current pricing: Hein-Werner Customer Support, 10939 N. Pomona Ave. Kansas City, MO 64153. Phone:

(816)891-6390; E-mail: customerservices@heinwerner-automotive.com

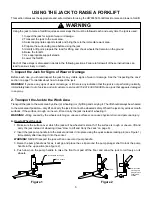

Replacement Parts for HW93659 Frame

Figure 9 - Parts Illustration for HW93659 Frame

Grease pin and clevis at assembly before

installing power unit and roll pin.

16

17

6

21

23

22

24

1

5

1 4

9

1

3

12

11

3

19

10

1

18

5

2

20

4

7

8

Item

Part#

Description

Qty.

1

239603

Handle Assembly

1

2

239604

Pump Handle Weldment

1

3

239605

Handle Lock and Hooks

1

4

239606

Retaining Ring, E, 3/8”

4

5

239607

Handle Pivot Shaft, 3/8”

1

6

239608

Hydraulic Unit

1

7

239609

Link

2

8

239610

Pump Pin

2

9

239611

Roll Pin, 1/4”Dia x 1-3/8”L

1

10

239612

Capscrew, Self- Locking

1/2-20UNFx1 1/2L

1

11

239613

Trunnion

2

12

239614

Retaining Ring, E, 3/4”

2

Item

Part#

Description

Qty.

13

239615

Washer, 1” OD

2

14

239616

Wheel, 3” Dia.

2

15

239617

Axle, 3/4”Dia

2

16

239618

Lift Pad

1

17

239619

Frame

1

18

239620

Lift Pad Pin 9/16D x3 3/8L

1

19

239627

Quick Release Pin, 5/16D

1

20

239602

Pipe Plug, 1/8”

1

21

239628

Knob

1

22

239601

Roll Pin, 1/8D x 1 5/8L

1

23

239625

Roll Pin, 5/32D x 3/4L

1

24

239626

Spring, Modified Torsion

1

-

239893

Label Kit

-

12