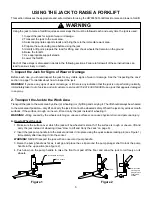

B. How to Lift and Carry the Jack

1. Identify the proper lift points on the jack (see Figure 3). The jack should be lifted using both the toe lift point and

the rear frame lift point.

WARNING!

NEVER use the pump handle to lift the jack. The pump handle is not a properly balanced leverage

point for lifting the jack. In addition, a pump handle that is not properly pinned into the socket (with the quick

release locking pin) may slip out of the socket and cause the jack to fall.

2. Lift and carry the jack. Whenever possible, have someone else help you lift and carry the jack.

• The jack weighs 68 lb. (30.8 kg).

WARNING!

DO NOT attempt to lift the jack if you have any physical condition that prevents you from safely

lifting this amount of weight. If you weigh less than 150 pounds, NEVER lift the jack without assistance.

• ALWAYS lift using proper lifting techniques—squat, keep your back straight, and use your legs to do the lifting.

WARNING!

NEVER bend your back or lift the jack with your back.

3. Select Appropriate Support Stands and Bring Them to the Immediate work Area

It is important that appropriate support stands are used. Hein-Werner manufactures support stands that are made

specifically for forklifts.

WARNING!

Use appropriate stands to support the load immediately after lifting. NEVER use the jack to support a load.

Failure to follow all of these instructions can result in jack instability and loss of a load.

4. Prepare the Surrounding Area Before Using the Jack

It is important that the surrounding area be prepared properly before raising a load.

WARNING!

Failure to follow all of these instructions can result in jack instability and loss of a load:

• Use the jack only on hard, level surfaces capable of safely supporting the load.

• The jack’s front footpad and rear wheels must ALWAYS remain in direct contact with the floor.

• NEVER attempt to lift from a polished or greasy floor.

• Clear the surrounding area of personnel, tools, equipment, and make sure appropriate support stands and chocks

are available for use in the immediate area.

If these conditions cannot be met, move the forklift and jack to an area where the lift can be performed safely.

Figure 3

Toe Lift Point

Rear Frame Lift Point

Quick Release Locking Pin

Pump Handle

6