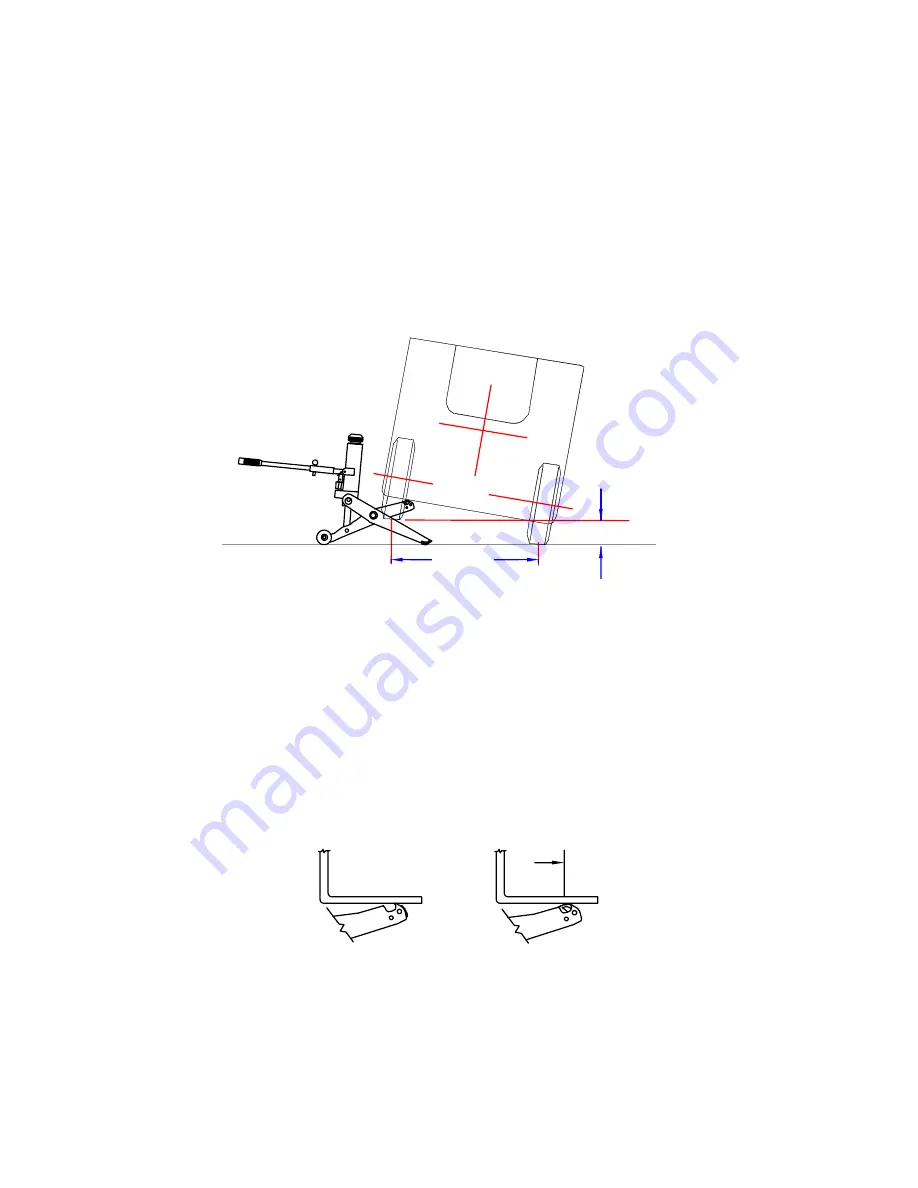

5. Identify a Lift Point, Prepare the Load for Lifting, and Chock Wheels

Before lifting a forklift with the jack, you need to identify a lift point and prepare the load for lifting.

1. Remove any load from the forks of the forklift and lower the forks to the ground.

2. Identify a lift point at the rear or side of the forklift.

WARNING!

When selecting a lift point, it is very important that you consider the following:

• Position the jack so that, as the forklift is lifted, the load will be balanced on the forklift tires that remain on the

ground.

• When raising a forklift from one end, always chock the wheels that will remain on the ground.

• Make sure at least two wheels of the forklift remain in contact with the floor at all times. NEVER raise a 3-wheeled

forklift from the 2-wheeled end or from the side. NEVER use the jack to raise all four wheels of the forklift from the

floor. NEVER raise the forklift higher than 1/4 its tread width (see Figure 4).

Figure 4

Tread Width

Height

3. Examine the lift point carefully and ensure that it is strong enough to resist the lifting force of the jack without

damaging the forklift or machinery.

• If is preferred to lift the forklift at a point where a structural member will be cradled in the lift arm notch at the end

of the lift arm (see Figure 5A).

• If no structural component on the forklift is present at the desired lifting point, weld a steel bar to the forklift to

create a structural member (as in Figure 5A).

• If no structural component exists and one cannot be created, flip the serrated lift pad into an upward position

and choose a lift point at least 3” inward toward the center of the vehicle on a flat surface (see Figure 5B).

Figure 5A Figure 5B

7

3"

Min.