9

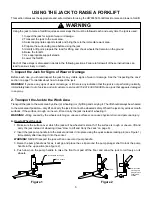

7. Use Appropriate Support Stands

WARNING!

This jack is a lifting device only! Use appropriate stands to support the load immediately after lifting. NEVER use

the jack to support a load. NEVER allow any part of your body under the raised load until it is properly supported by stands.

1. When the forklift has been raised to the desired height, place appropriate support stands under the forklift to support

it according to the forklift manufacturer’s recommendations. Hein-Werner manufacturers support stands for this

purpose. Also, read and follow all instructions and warnings provided with the support stands.

2. Lower the forklift onto the stands by slowly turning the release knob on the jack counterclockwise.

3. Remove the jack and move it away from the work area before starting work.

4. Chock the wheels that will remain on the ground.

8. Lower the Forklift

WARNING!

To avoid serious injury or death, NEVER drive the forklift off the jack or attempt to move a forklift that it is

elevated by the jack

.

1. Use the instructions from Step 5 (Raise the Forklift) to raise the forklift off the jack stands.

2. Carefully remove the stands from beneath the forklift and place them away from the work area.

3. Slowly turn the release knob counterclockwise to lower the forklift to the floor.

WARNING!

Turn the release knob slowly to prevent the possibility of the jack from kicking out from under the forklift.

4. Lower the jack completely and move the jack and chocks away from the work area.

INSPECTING THE JACK

The owner must inspect, or appoint a knowledgeable person to inspect the jack for signs of damage, corrosion,

excessive wear, abnormal operation, or any other potential problem. Inspection should be performed before each

use.

NEVER use a jack that appears to be damaged in any way. If any irregularities or problems are detected during

an inspection, the jack must be removed from service immediately and repaired. Contact customer service at the

address and numbers shown on the back cover of this manual to report any problems.

If a jack is subjected to an abnormal shock or load, it must immediately be removed from service and inspected for

damage.

!

WARNING

Use the following procedures to inspect the jack for wear or damage:

• Inspect the serrated lift pad regularly, and remove a jack from service if it is cracked, chipped, rusted, or shows signs

of wear.

• The jack should raise and lower smoothly through its full range. Inspect the lift arm for damage such as bends and /

or twists.

• Check the wheels to make sure that they are not damaged and that they rotate freely.

• Make sure that all components are present on the jack and are in good operating condition.

• Replace any missing or damaged components or decals before putting the jack back into service.