Cattle clipper Xperience

31

1.5 - 2 mm

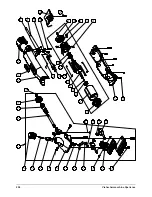

Fig. 9

Install the new lower blade. Align it so that the

polished surface of the lower blade protrudes

approx. 1.5 - 2 mm beyond the tips of the upper

blade.

Tighten the comb plate screws.

NOTE

►

Work only with sharp clipping blades and replace dull blades and blades with missing

teeth. Proper sharpening of clipping blades is only possible by an expert using

specialised equipment. When faced with the need to sharpen the blades, contact your

service centre.

6.6 Lubrication

Fig. 10

To obtain a well-clipped animal and to increase the

life of the device including the clipping head, it is

necessary to apply a thin coat of oil between the

upper and lower blades. All other moving parts of

the clipping head must also be lubricated.

Apply some drops of oil onto the clipping blades

and into the lubrication opening.

NOTICE

Possible damage to the clipper!

Insufficient oiling of the clipping head will lead to warming and will shorten the life of the

clipper and its blades.

►

Oil the clipping blades adequately during the clipping session, at least once every 15

minutes, so that they do not run dry.

►

Use only the special oil supplied or a paraffin oil meeting the ISO VG 15 specification.