17

GASOLINE CHAIN SAW

GUIDE BAR

Reverse the bar occasionally to prevent partial wear.

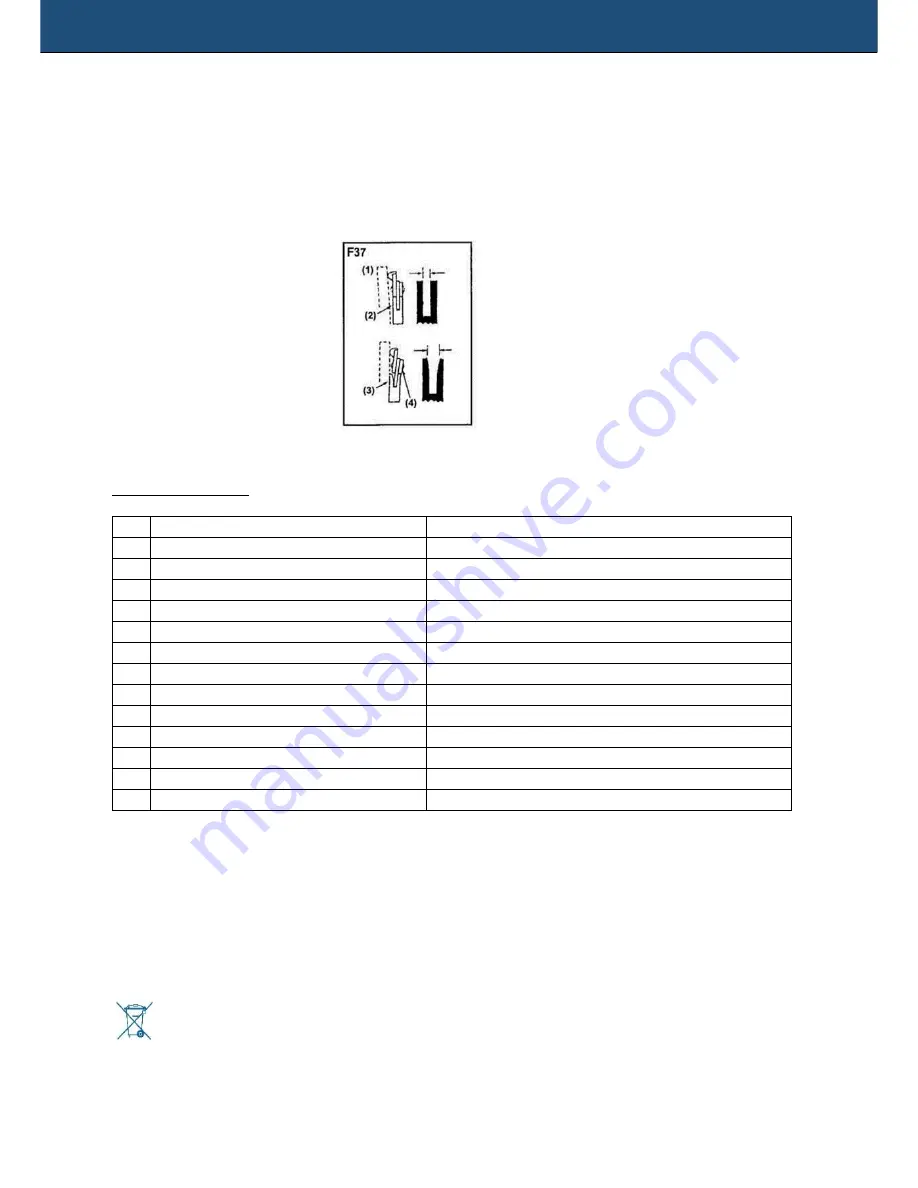

The bar rail should always be a square. Check for wear of the bar rail. Apply a ruler to the bar and the

outside of a cutter. If a gap is observed between them, the rail is worn. Such a bar needs to be corrected

or replaced. (F37)

(1) Ruler

(2) Gap

(3) No gap

(4) Chain tilts

11. SPECIFICATIONS*

1

Displacement (cm

3

)

58

2

Fuel

Mixture (Gasoline 25 : Two-cycle oil 1)

3

Fuel tank capacity (ml)

550

4

Chain oil

Motor oil SAE#10W-30

5

Oil tank capacity (ml)

260

6

Ignition system

Pointless (CDI)

7

Carburetor

Walbro

8

Spark plug

XIAHUI L7T

9

Oil feeding system

Automatic pump with adjuster

10

Sprocket

(Teeth x Pitch): 0.325

11

Guide bar type

Sprocket nose

12

Guide bar size(in)

20”

13

Saw chain pitch (in)

0.325

14

Saw chain gauge (in)

0.058

*Specifications are subject to change without notice.

RECYCLING

Electrical and electronic equipment waste (WEEE) might contain dangerous materials which can have a

negative impact on the environment and human health if not collected separately.

This item is in conformity with the European Directive EU WEEE (2012/19/EU) and is marked with an

electronic and electrical waste logo graphically represented in the image below.

This icon shows that WEEE should not be collected with household waste but separately.

We recommend you to consider the following:

- Materials and components used when manufacturing this item are high quality materials

which can be reused and recycled;