2 General

6

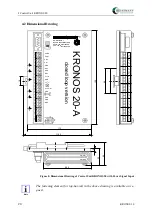

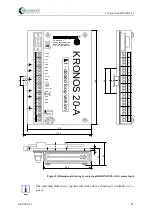

KRONOS 20

Resolution

1250 steps (E-LES 30)

2000 steps (E-LES 50)

3800 steps (E-LES 80)

λ

map

100 points

Calorific value range

4..200 MJ/m³

Gas filter requirement

max. mesh size 50 µm

Admissible concentration of (H

2

S)

hydrogen sulphide

max. 0.1 %

Fuels might not hold any corrosive constituents. If in doubt consult HEINZMANN

See below for detailed specifications of single components.

Performance Range:

E-LES 30-x:

80 kW (landfill gas) ... 250 kW (propane)

E-LES 50-x:

250 kW (landfill gas) ... 800 kW (propane)

E-LES 80-x:

800 kW (landfill gas) ... 2500 kW (propane)

The indicated performance ranges are based on an assumed engine efficiency of 35%.

assumed calorific value (H

u

):

natural gas:

34 MJoule/nm³

landfill gas:

18 MJoule/nm³

propane:

90 Mjoule/nm³

The volume flow rate of the E-LES gas valve depends on the gas mixer and its design. The

indicated performance range is valid only if the gas valve design is done by

HEINZMANN. For applications combined with other gas mixers the volume flow rate can

be 50% lower.

2.5

Operational Principle

The basic components of a conventional gas mixing system are:

•

Gas mixer

•

Main Adjusting Screw (MAS)

•

Zero pressure regulator (ZPR)

Gas-air-fuel-ratio is determined essentially by the configuration of the gas mixer. On con-

dition that the output pressure of the zero governor (ZPR) always corresponds to the air in-

put pressure of the gas mixer, the air-fuel-ratio remains constant for different volume flow

rates or engine loads. In practice, gas bores are chosen slightly greater than theoretically

Summary of Contents for E-LES 30

Page 2: ......

Page 8: ......

Page 104: ...17 Order Form for KRONOS Systems 96 KRONOS 20 17 Order Form for KRONOS Systems...