HEINZMANN

®

Fehler! Verweisquelle konnte nicht gefunden werden.

Fehler! Verweisquelle konnte nicht gefunden werden.

40

KRONOS 20

7

Parameter Settings for Control Unit KRONOS 20

The software for the HEINZMANN digital controllers conceived so that parametrizing can be

done either by the engine manufacturer or by the final customer if the necessary instruments

(communications tool) are available. Only a few basic parameters are pre-set in the

HEINZMANN factory. This means that the digital governor usually gets its definitive set of

data from a source external to HEINZMANN.

An exception is made for control units delivered in greater numbers. If HEINZMANN has

been provided in advance with a definitive set of data, this data can be trasferred to the units

in the factory.

As a principle, initial programming should always be conducted by experienced personnel and

must be checked before first commissioning the engine.

How parameter are adjusted and what meaning they have is explained in detail in the manual

"Basic information 2000".

The following sections describe the possibilities of parametrizing the control unit:

7.1

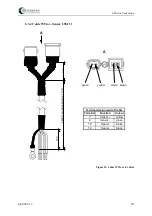

Parametrization with the Hand Held Programmer 3

All parametrization can be done by means of the hand held programmer ‘Programmer 3’.

This handy device is particularly suited for development and series calibration as well as

for servicing. This unit needs no external power supply.

7.2

Parametrization with the PC / Laptop

Parametrization can also be conducted using a PC and the comfortable HEINZMANN

communication software DcDesk 2000. As compared with the hand held programmer, it

offers the great advantage of having various curves graphically represented on the screen

and being at the same time able to introduce changes as well as of having time diagrams

displayed without an oscilloscope when commissioning the control unit on the engine. Fur-

thermore, the PC offers a better overview as the PC programme has a menu structure and

allows to have several parameters continuously displayed.

Besides, the PC programme permits to save and download the operational data to and from

data mediums. Additional there is the following usefull application:

Once parameterization has been completed for a specific engine type and its application,

the data set can be stored to disk. For future applications of similar type, the data sets

can be downloaded and re-used with the new control units.

Summary of Contents for E-LES 30

Page 2: ......

Page 8: ......

Page 104: ...17 Order Form for KRONOS Systems 96 KRONOS 20 17 Order Form for KRONOS Systems...