24

Problem /

Symptom

Possible Cause

Possible Solution

Vehicle will not turn on

Battery voltage too low

Charge battery

Battery not connected

Re/connect battery

Damaged battery

Replace battery

Transmitter will not

turn on

Battery voltage too low

Charge or change batteries

Battery/ies installed improperly

Correct installation

Short radio range

(Vehicle stops

responding to

transmitter at short

distances)

Damaged or improperly installed receiver

and antenna

Check receiver antenna for damage. Ensure antenna is properly

installed in tube and mount, extending perpendicular from the

ground. Ensure all connections are secure

Receiver is malfunctioning

Replace receiver

Battery voltage too low

Replace or recharge batteries in transmitter and vehicle

Steering not responding

as expected

Trim not set properly

Adjust steering trim

Screws too tight on steering parts

Adjust screws to allow for free motion

Fasteners have become loose

Check and tighten all fasteners to as-new condition, be careful to not

over tighten

Vehicle not responding

as expected to

transmitter

Trims not set properly

Adjust throttle and/or steering trim

Radio system lost bind

Re-bind radio system

Bad electrical connections

Check motor and battery plugs to ensure they are fully connected

Wheels twitch while

vehicle is idle (controls

at neutral)

Transmitter too close to receiver (<1m)

Increase distance between the units

Receiver wire damaged

Inspect antenna for damage and replace if necessary

Receiver antenna not installed in vertical

position

Install in mount with care to not damage antenna wire

Steering will not trim

straight, always has

right or left bias

Binding in steering system

Inspect and correct any binding components or loosen screws if

over tight

Front wheels too tight

Check and adjust wheel nuts to ensure the wheels are not too tight

Vehicle top speed and

acceleration is slow

Battery voltage too low

Charge battery

Drivetrain has too much friction

Check for debris/excessive wear on gears, inspect bearings

Gear mesh too tight

Loosen gear mesh

Pinion gear is loose

Check and tighten set screw on motor pinion

Broken Differential

Check differential and ensure the outdrives are secured and gears

intact. You should not be able to pull them out

Drive pin missing

Check for missing wheel pins (behind wheel hexes), or dogbone pins

ESC not set to transmitter

Follow ESC instructions to set to transmitter

Wheels not spinning

freely

Wheels too tight

Check and adjust wheel nuts

Differentials stripped

Check differentials and replace/repair if necessary

Battery charge stops

lasting as long as it

used to

The battery has become old

Replace battery

Battery not charged completely due to

insufficient charge time

Charge for longer period of time or try a peak detection charger. We

recommend the Radient Primal RDNA0041

Gear mesh too tight

Check and reset gear mesh setting

Charger, battery, wires, or plug has

malfunctioned

Check all connections and wires for damage or excessive wear and

replace if necessary

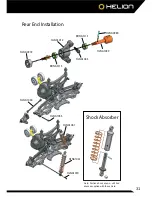

Shocks and/or arms

covered in oil

Shock O-ring seals are worn

Replace O-rings and refill shock with oil

Top shock cap too loose or over tightened

Check tightness (finger tight), refill shock oil

Bottom shock cap dislodged

Check installation, refill shock oil

Spur gears stripping

Gear mesh too loose

Tighten gear mesh for proper backlash

Fasteners loose or missing

Check for loose fasteners and bad bearings.

Pinion gear too worn out

Replace pinion gear

Summary of Contents for conquest 10MT XB

Page 41: ...www Helion RC com ...