...GENERAL CARE AND MAINTENANCE CONTINUED...

13

1/10th SCALE 4x4

ELECTRIC SHORT

COURSE TRUCK

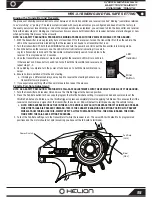

ii. Check how much movement is allowed (backlash) of the spur gear before the pinion gear moves (this is mostly feel, not

visual). Check this movement in multiple places by rotating the spur gear approximately 1/6 rotation and rechecking.

iii. If the spur gear is allowed to move more than a very small amount, or if it there is no backlash, the gear mesh must be

adjusted. If there is a lot of movement, it is recommended to attempt to tighten the mesh. Attempted adjustment should

only improve the situation; if the mesh was correct to begin with, you will know what that feels like, and if it wasn’t cor-

rect, it will be when you are done after following these procedures.

iv. Setting the gear mesh.

01). Loosen the top screw securing the motor plate to the motor mount, only enough to allow the plate to move.

Check and ensure there is no debris in the gears affecting the mesh.

02). Slide the top of the motor plate away from the center of the chassis, insert a strip of notebook paper between the

pinion and spur gear, then slide the motor plate back until there is no backlash. You will have to push relatively

hard to ensure the paper is pressed all the way into the teeth.

03). Hold the motor snugly in position while retightening the screw.

04). Rotate the spur gear to feed the paper out of the mesh, re-check the gear mesh and adjust again if necessary.

v. Re-install the spur gear cover.

WARNING: Never operate your vehicle with the spur gear cover removed. Severe injury, damage to electrical components,

and excessive wear and tear on drivetrain may result.

4. Slipper Clutch Adjustment: The slipper clutch is used to limit the maximum torque that is transferred from the motor to the

wheels, and thus the ground. This is setting varies for different surfaces and thus is important to get correct for each surface

that you operate your vehicle on. Setting the slipper clutch properly will allow for maximum traction and acceleration. Over

tightening the slipper clutch can lead to excessive drivetrain wear and eventually damage. Running a setting that is too loose

will cause the vehicle to under-perform and could cause the clutch to overheat and cause damage to the spur gear.

a. General guidelines for setting the slipper clutch.

i. When running on a surface with a lot of traction or when running a faster motor, the clutch should be tightened.

ii. When running on a surface with low traction or when running a slower motor, the clutch should be loosened.

iii. If the slipper clutch has been run with a setting that is too loose, the slipper pads will experience excessive wear and

may need replacement. See the spare parts guide at the back of this manual for assistance with locating the parts you

need to service your vehicle.

iv. If the slipper clutch is set too tight on high traction surfaces, the front of the wheels may come off the ground, produc-

ing a “wheelie”. While this looks impressive, we caution you to readjust the slipper to prevent the “wheelie” since you

cannot turn the vehicle to avoid collisions when the front wheels are in the air.

5. Shocks: Periodically inspect the shocks for smooth motion, leaking oil and dirt residue build up around the shaft.

a. Do not allow dirt to build up around the shock shaft and bottom of the shock. Doing so will reduce the life of the shock and

cause a shock to leak oil. Be sure to clean the shocks regularly with a clean and dry soft bristle brush and/or rag.

b. Signs to look out for determining if your shock needs to be maintained or rebuilt.

i. Oil around the shaft means the oil leaked from inside and needs to be replaced.

ii. Persistent oil around the shock shaft or lower portion of the shock typically points to damaged O-rings which will need

replacing. See your local hobby dealer for replacement parts.

iii. Refilling your shocks:

01). Remove shock from vehicle, remove spring and top cap.

02). With shock shaft extended, add oil to top of body (use only 100% silicone oil).

03). Slowly compress the shock shaft 50% of travel using a towel or paper napkin to clean up overflowed oil.

04). Slowly reinstall the shock cap and check for free motion of shock.

05). It is normal for the shock to rebound (with the spring removed) after full compression and release.

iv. Replacing the O-rings:

01). Disassemble shock and remove shaft from the body.

02). Carefully remove lower cap by unscrewing from the shock body.

03). Remove the O-rings and spacer and replace with genuine replacement parts.

04). Re-assemble the shock following the refilling instructions above.

6. Tires and wheels:

a. Inspect the tires to ensure they are properly glued to the wheels. The tires on your vehicle come pre-glued from the factory;

however after running your vehicle it is possible for the glue to come loose in some areas.

i. To reattach the tire to the wheel, use hobby grade Cyanoacrylate (CA) glue and apply small amounts (one drop at a

time) between the tire and wheel. Allow the glue to fully dry before operating your vehicle.