EN

EN

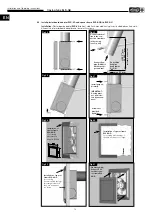

Casing type ELS-GU

Installation and Operating Instructions

4

Extract air lines must be leak-proof, stable and made from fireproof material class A according to DIN 4102 for more

than two full floors. They must be provided or thermally insulated so that no condensation damage occurs. A sufficient

number of cleaning openings with leak-proof closures must be positioned so that the extract air lines can be cleaned

easily. Screwable cleaning openings are not permitted.

The main line should be straight and vertical with a constant cross-section. In case the main line is not vertical, it must

be mathematically verified that the requirements according to DIN 18017, pt.3, section 3.1.3 are fulfilled. When meas-

uring the main line, it is required that all fans are simultaneously operated at full output. Throttle devices are not per-

mitted.

The diameter of the main line can be determined from the dimensioning diagram (Helios main catalogue). In this respect,

it should be noted that there are increased pressure losses for a discharge line length over 1.5 m and a floor height over

2.75 m, which must be compensated for with a larger main line cross-section.

The Helios ELS software can be used for dimensioning. Available via the Helios website:

www�heliosventilatoren�de

.

Maximum two ELS fan units per floor can be connected to a common main line. The ventilation of other rooms in an

apartment must not take place via the same fan that is used to ventilate the bathroom and toilet. Observe minimum

bending radius of connecting lines R = DN.

The design and installation of ventilation system must comply with the building acoustics regulations (DIN 4109 sound

insulation in building construction).

2�9 General information

a.) If the casings are used in highly resonant lining boards (e.g. chipboard, gypsum or fibre silicate boards), then the

transmission of structure-borne sound must be prevented with elastic spacers.

b.) Supply air feed: Each room for ventilation must have a non-closable air vent opening of 150 cm

²

free cross-section.

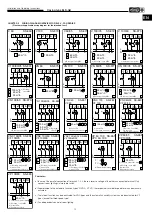

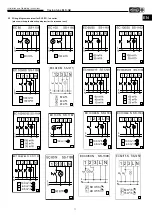

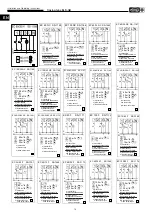

2�10 Electrical connection

The unit must be fully isolated from the power supply before all maintenance and installation work or before

opening the terminal compartment! The electrical connection must only be carried out by an authorised elec-

trician according to the information in the enclosed wiring diagrams�

Observe the yellow label stick in the casing!

The relevant standards, safety regulations (e.g. DIN VDE 0100) and the technical connection regulations of the ener-

gy supply companies must be observed. An all-pole mains switch/isolator, with at least a 3 mm contact opening (VDE

0700 T1 7.12.2 / EN 60335-1) is mandatory. The rated voltage and frequency must be consistent with the information

on the type plate. The power cable must be introduced so that, in case of water exposure, water entry along the pow-

er-supply cable is impossible. The cable must never be placed over sharp edges. The units are protection type IPX5 (jet

water-proof ) and correspond to protection class II.

The electrical connection is carried out at the connection terminals in the casing. The corresponding wiring diagram

for the respective fan type and casing must be observed. A control unit parallel to the light is recommended in rooms

without windows (exceptions: ELS-VF, ELS-VP).

The electrical connection must be fully isolated from the mains power supply until final assembly!

2�11 Spare parts

Spare permanent filter ELF-ELSD

Ref� no� 8190

Spare filter Packaging unit: 2 pcs, washable

Spare air filter for second room intake unit ELS-ZS

Ref� no� 3042

1 kit = 5 pcs

Spare filters can be ordered online at

www�ersatzluftfilter�de

2�12 Approval

General technical approval, DIBt (German Institute for Structural Engineering).

Approval number:

Z-51�1-193

NOTE

m

DANGER

NOTE