Temperature Control System WHS HE

Installation and Operating Instructions

4

EN

EN

m

Risk from pressurised fittings!

With regard to pressurised fittings, there is a risk of injury from the uncontrolled discharge of media or suddenly deta-

ched parts in case of improper handling, overpressure or defects.

– Once installation is complete, the leak tightness of the internal components of the fitting group and the external

system connections must be checked.

– Always maintain permissible operating pressures during operation.

– Ensure that defective components which are pressurised during operation are immediately replaced by qualified

personnel.

– Always carry out maintenance and dismantling work on the unpressurised system.

m

Risk of burns from hot fittings!

Fitting group parts can become hot during operation and unprotected contract can cause burns.

– Decommission the heating system and allow it to cool down prior to all work (conversion, maintenance, dismantling).

– Wear protective gloves if necessary.

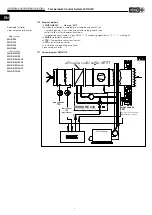

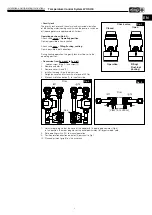

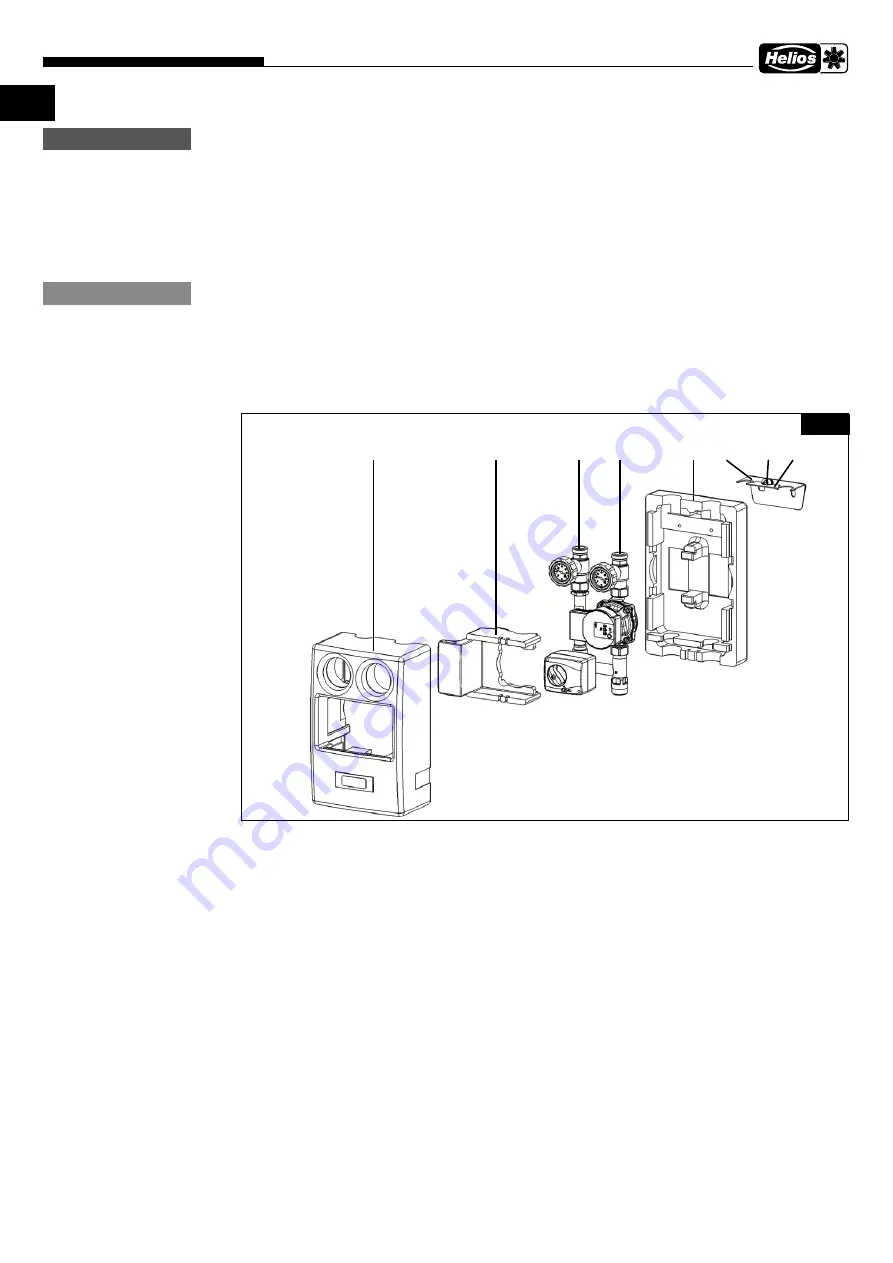

1. Remove the front thermal casing insulation (1) and the insert block (2)

2. Loosen screw (7) on wall bracket (6)

3. Remove the flow (3) and return line (4) of the assembly from the rear casing insulation (5)

4. Determine the position of the assembly on the wall and secure the wall bracket with the supplied screws

TIP: Use the rear insulation as a drill template!

5. Place rear insulation (5) on wall bracket, mount flow and return line in the wall bracket and secure against turning

with the locking plate (8) and screw.

6. Once the work has been completed, carry out the water connections

7. Replace insert block (2) and front casing insulation (1)

m

WARNING

m

CAUTION

1

2

3

4

5

6

7 8

Fig� 2