US

DE

Automation Instructions CPK • 10-2015 •106-29009

Servicing

19

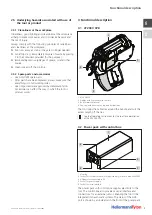

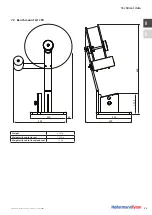

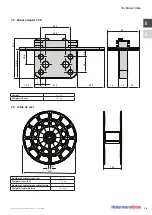

5 .5 .3 Geometries of materials for bundling

Diameter

max. 20 mm

Rectangle sizes

max. 12 mm x 27 mm

Square sizes

max. 13.8 mm x 13.8 mm

Distance between material

for bundling and flat

min. 42 mm

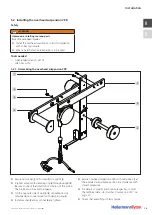

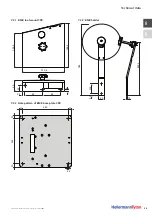

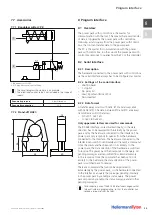

5 .6 External material stock monitoring

An external sensor is needed for monitoring the end of the

material. The sensor connects to the power pack with

control box and is incorporated into the on-tool display. A

message shows on the on-tool display to draw attention to

the end of the material,

„Overview of interfaces, power

pack with control box“ on page 23.

The external sensor is not included in the scope of supply.

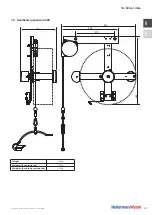

5 .7 Check of applied cable ties

The HellermannTyton components cannot perform the

check of the applied cable ties. An external monitoring

system (e.g. camera monitoring) is required for this check.

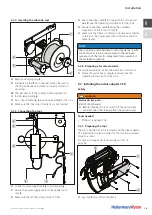

6 Servicing

6 .1 Important notes

Regular servicing is essential in order to ensure that the tool

remains in safe working order (see the maintenance schedule

in the Operating Instructions for the tool)

.

CAUTION

Crush hazard when jaws close.

f

Do not insert finders between top and bottom jaws.

f

Do not keep fingers on the trigger.

f

Always keep the power pack switched OFF while

servicing is in progress.

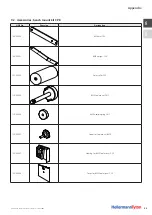

6 .2 Spare parts

Spare parts and accessories can be ordered directly from

your national HellermannTyton representative,

à

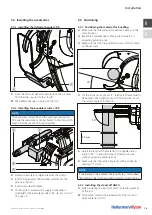

6 .3 General servicing operations

The operations involved in servicing the tool and the power

pack are described in the Operating Instructions for the tool

(see the section entitled "Servicing" in the Operating

Instructions for the tool).

f

Check the tool and the accessories regularly to make

sure that everything is in full working order.

f

Dispose of waste material at regular intervals.

f

Check the compressed-air lines for leaks (see the

operating instruction for the compressed-air equipment).

The compressed-air equipment is not included in the scope

of supply.

f

Have faulty compressed-air lines replaced immediately.

f

Check electrical lines for damage.

f

Have faulty electrical lines replaced immediately.

Summary of Contents for Autotool 2000 CPK

Page 1: ...A u t o t o o l 2 0 0 0 TOC Cover Automation Instructions Automatisierungsanleitung...

Page 2: ...2 US English DE Deutsch Automation Instructions 3 Automatisierungsanleitung 37...

Page 36: ...US DE Automation Instructions CPK 10 2015 106 29009 Appendix 36 9 5 Cable tie strip...

Page 70: ...US DE Automatisierungsanleitung CPK 10 2015 106 29009 Anhang 70 9 5 Bandkette...

Page 71: ......