US

DE

Automation Instructions CPK • 10-2015 •106-29009

Program interface

29

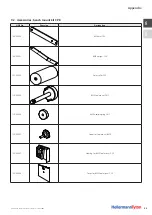

7 .7 Accessories

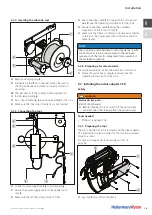

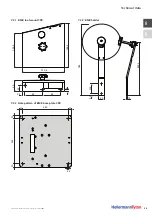

7 .7 .1 Bandoleer cutter CPK

1

2

1 Bandoleer cutter CPK

2 3/2-way directional-control valve

The circuit diagram shown here is an example.

The directional-control valve is not included in the scope of

supply.

Pneumatic pressure

6 bar, filtered air

Pneumatic connection

PK-4

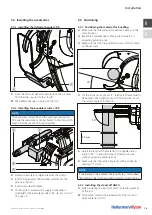

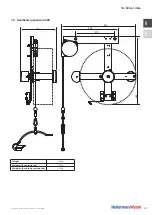

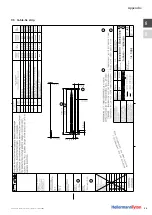

7 .7 .2 Stand-off HH20

45

40

13

55

24

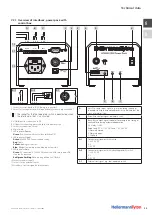

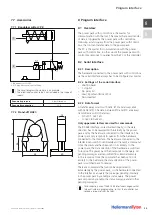

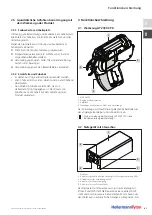

8 Program interface

8 .1 Overview

The power pack with control box is the master for

communication with the tool. This means that every transfer

of data is triggered by the power pack with control box.

Following a status query from the power pack with control

box, the tool can transfer data to the power pack.

The PC is the master for communication with the power

pack with control box, in other words the power pack with

control box responds to queries from the PC or the controller.

8 .2 Serial interface

8 .2 .1 Description

The hardware connected to the power pack with control box

via the serial interface always has to be configured as master.

8 .2 .2 Settings of the serial interface

• 256000 baud

• 1 stop bit

• No parity bit

• Least Significant Bit sent first

• Non-inverted

8 .2 .3 Data format

A transfer always starts with 0x02 (STX) and always ends

with 0x03 (ETX). The data between STX and ETX are always

transmitted as ASCII characters:

• 0: 0x30 1: 0x31 etc.

• A: 0x41 B: 0x42 etc.

Only uppercase letters are used for commands .

The RS-485 interface is used bi-directionally, so the data

direction has to be reversed both internally by the power

pack and by the hardware connected to the interface. The

power pack only responds to queries from the hardware

connected to the interface. The hardware connected to the

interface can switch to send mode and transmit a command.

Once the command has been sent in its entirety to the

power pack, the data direction of the hardware is switched

to receive. The power pack then responds to the query. All

pending messages are transmitted from internal memory

in this response. Once the command has been sent in its

entirety to the hardware, the data direction of the power

pack is switched back to receive.

There are commands that cannot be responded to

immediately by the power pack, so the hardware connected

to the interface can query the messages pending internally

in the power pack by sending a status query. The power

pack responds by sending the status message and all other

pending messages.

For bi-direction use of the RS-485 interface changeover has

to be activated in programming, so that the controller can

receive a response from the tool.

Summary of Contents for Autotool 2000 CPK

Page 1: ...A u t o t o o l 2 0 0 0 TOC Cover Automation Instructions Automatisierungsanleitung...

Page 2: ...2 US English DE Deutsch Automation Instructions 3 Automatisierungsanleitung 37...

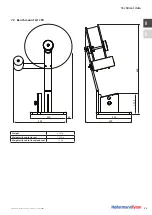

Page 36: ...US DE Automation Instructions CPK 10 2015 106 29009 Appendix 36 9 5 Cable tie strip...

Page 70: ...US DE Automatisierungsanleitung CPK 10 2015 106 29009 Anhang 70 9 5 Bandkette...

Page 71: ......