Helmer Scientific i.Series

®

and Horizon Series

™

Refrigerator - Pass-Thru

Service and Maintenance Manual

360429/A

38

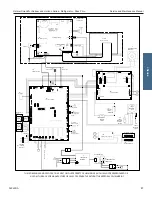

8.2 iPR Models; 226 and 458 Configurations with i.Lock

™ Interlock

i.C3 DISPLAY BEZEL

CLEAN ROOM SIDE

C

O

M

2

N

.C

. 2

i.C3 Power PCBA

(iD)

N/L2

L1

F4

Battery

BYPASS

ON

Magnetic Lock

Access Control

(AXb)

C

O

M

2

N

.C

. 2

C

O

M

2

N

.C

. 2

C

O

M

2

N

.C

. 2

Magnetic Lock

Access Control

(AXb)

Magnetic Lock

Access Control

(AXb)

Magnetic Lock

Access Control

(AXb)

MAG #2

MAG #4

DBL DR ONLY

MAG #1

MAG #3

DBL DR ONLY

SW #1

SW #3

DBL DR ONLY

SW #2

SW #4

DBL DR ONLY

ANTE ROOM SIDE

RIGHT SIDE

LEFT SIDE

E

D

I

S

T

F

E

L

E

D

I

S

T

H

G

I

R

FROM

PSU +V

TO

MAG +V

FROM

PSU GND

TO

SW COM 2

FROM CLEAN ROOM SIDE

SW N.C.2

TO ANTE ROOM SIDE

MAG 0v

MAG-1

MAG-2

MAG-3

MAG-4

PSU +V

0v

+V

0v

+V

0v

+V

0v

+V

MAG-4

MAG-2

MAG-3

MAG-1

FROM ANTE ROOM SIDE

SW N.C.2

TO CLEAN ROOM SIDE

MAG 0v

DBL DR ONLY

DBL DR ONLY

DBL DR ONLY

DBL DR ONLY

KEY SWITCH

+VDC

GND

Ante Room

Clean Room

THESE DRAWINGS AND SPECIFICATIONS ARE THE SOLE PROPERTY OF HELMER INC. AND SHALL NOT BE REPRODUCED OR

USED AS THE BASIS FOR MANUFACTURE OR SALES OF APPARATUS WITHOUT THE APPROVAL OF HELMER INC.

SW-1

SW-2

SW-3

SW-4

PSU 0V

MAG-1

SW-2

MAG-3

SW-4

SW-1

MAG-2

SW-3

MAG-4

1

2

3

4

5

6

1

2

3

4

1

2

3

4

1

2

3

4

5

6

i.Series