Helmer Scientific Platelet Agitator

Service Manual

360391/A

7

2.4

Placement Leveling and Setup (Stand-alone)

CAUTION

• To prevent damage, do not use trolley or trolley drawer to lift agitator.

• The communication switch is fragile, do not use excessive force when changing the setting.

NOTICE

• When lifting platelet agitator, lift using the ends of the base.

• If the base is not accessible, lift using the ends of the trolley

Notes

• Leveling feet may crack or wear over time. Check leveling feet periodically and replace as needed.

• For setpoint of 72 CPM, rotate the arrow into the center of the green zone. This is the expanded 72 CPM setpoint area.

•

For additional information regarding agitator setup, refer to the Platelet Agitator Pro Operation Manual.

1. Place platelet agitator on sturdy surface.

2. Adjust leveling feet to ensure platelet agitator is level.

3.

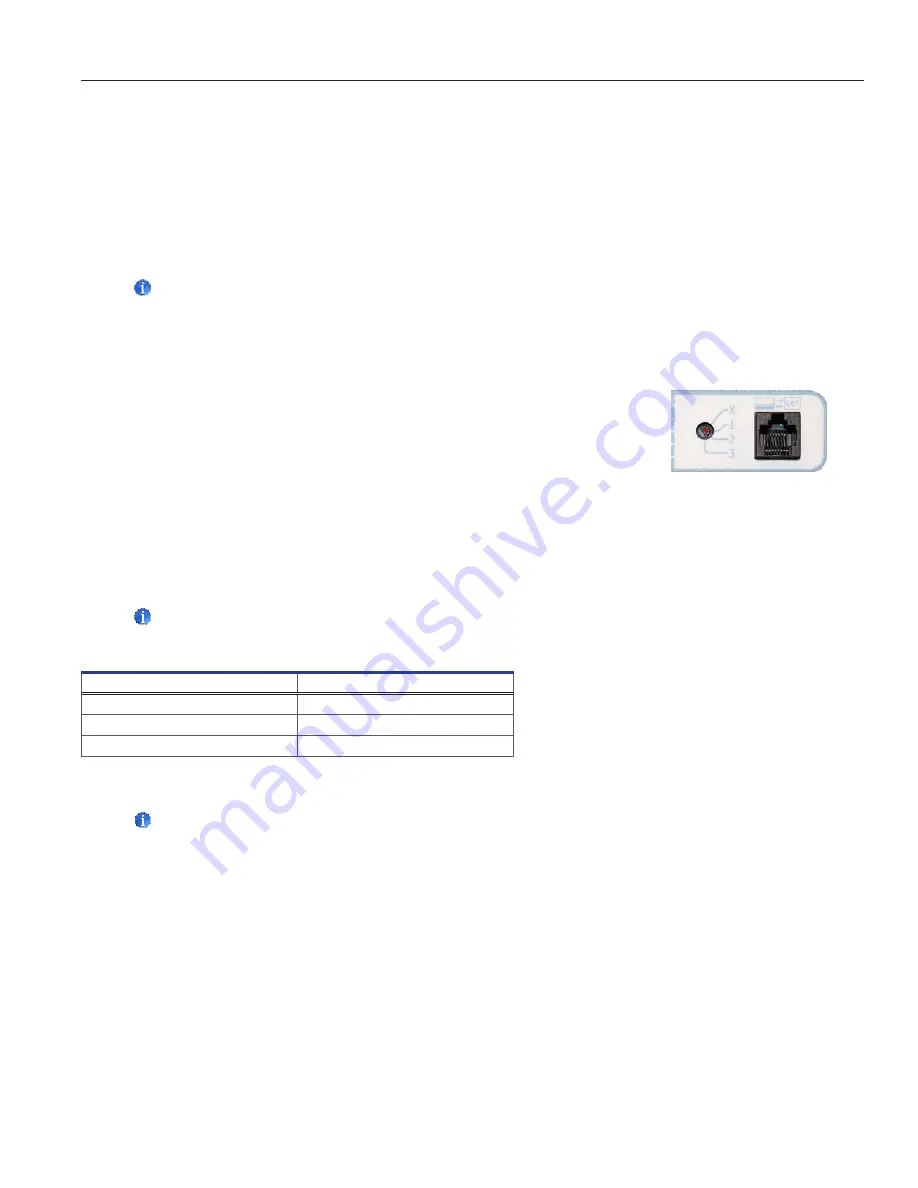

Using a small flathead screwdriver, turn the communication switch to the X position.

Ensure the arrow (shown in red for visibility in the picture) is pointing to the X.

2.5 Configure Platelet Agitator for Use in a Platelet Incubator (Optional)

Pro Series platelet incubators may only be fitted with Pro Series platelet agitators. When installed in a Pro Series platelet incubator,

the Pro Series platelet agitator can be monitored by the platelet incubator’s AgiTrak™ system. The AgiTrak™ system receives

alarm information through a direct connection from the platelet agitator’s alarm system to the platelet incubator’s alarm system.

Platelet Agitator and Platelet Incubator Compatibility

Note

Only Pro Series platelet incubators can monitor Pro Series platelet agitators.

Compatible Helmer Platelet Agitator

Platelet Incubator

PF15-Pro

PC100-Pro

PF48-Pro

PC900-Pro

PF96-Pro

PC1200-Pro

Install a Platelet Agitator in the Platelet Incubator

Notes

•

For additional instruction on configuring a platelet agitator in a platelet incubator, refer to the Platelet Incubator Pro

Operation Manual.

• Ensure data cable is carefully positioned to the right of the agitator to prevent damage caused by agitation motion.

• The agitator communication switch is fragile, do not use excessive force when changing the setting.

• To ensure continuous operation of linearly shifting loads, the location surface must adequately accommodate the full

weight of the incubator with installed agitator when loaded with product.

• Use only the manufacturer supplied coiled DC power cord when installing the Pro series agitator in a Pro series Incubator.

• Ensure the incubator AC power and battery back-up power are switched

OFF

prior to connecting the agitator power

cord to the incubator.

• Installation of agitator anchor brackets is recommended when an installed agitator is set at a speed greater than

72 cycles per minute (CPM). Anchor brackets are included with the agitator.

• The agitator motion alarm switch must be

ON,

and volume turned up to provide audible alarm backup in the event

communication is lost between the agitator and incubator.