360094-1/M

6

General Information

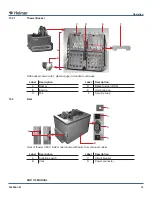

6 Installation

6 .1

Location Requirements

►

Has a sturdy, level surface

►

Has a grounded outlet meeting national electric code (NEC) and local electrical requirements

►

Is clear of direct sunlight, high temperature sources, and heating and air conditioning vents

►

Minimum 8” (203 mm) above

►

Access to a water supply

►

Adjacent to a sanitary drain or waste water container

►

Meets limits specified for ambient temperature and relative humidity

NOTE

If possible, drain or waste container should be located on same side as drain

port.

6 .1 .1 Placement

!

CAUTION

►

Ensure chamber has been drained before moving.

►

Unplug unit from AC power before moving.

6 .2

Install External Thermometer (Optional)

Install the external thermometer according to the manufacturer’s documentation. If using a Helmer DT1

digital thermometer, refer to the instructions on the CD shipped with the plasma thawer.

7

Maintenance Schedule

Maintenance tasks should be completed according to the following schedule. Refer to the service manual

for more detail on the various tasks.

NOTE

These are recommended minimum requirements. Regulations for your

organization or physical conditions at your organization may require maintenance

items to be performed more frequently, or only by designated service personnel.

Task

Frequency

Weekly

Quarterly

Annually As Needed

Clean the chamber and basket (DH2) or baskets

(DH4 and DH8).

Clean the exterior.

Clean the fan (100 V DH8).

Lubricate moving parts.

Check temperature calibration for the temperature

controller readout. Recalibrate if necessary.

Test the high temperature alarm.

Check the bearings on each basket for wear.

Replace if necessary.